6 Types of Procurement Strategies You Need to Know About

An effective procurement strategy outlines all the activities and procedures necessary to achieve your procurement, as well as overall business goals.

Historically, these strategies have primarily focused on financial performance and cost savings, but today, things are changing.

That’s why we’ve dedicated this article to six types of procurement strategies you should be aware of.

Each section will describe one specific strategy, outline key tactics commonly associated with it, and provide some real-life examples so you can see these strategies in action.

Plus, we’ll reveal one secret ingredient for the success of each of these strategies, no matter which tactics you choose to employ.

Let’s start with the one you’re probably already familiar with: the cost reduction strategy.

Cost reduction strategies focus on slashing expenses associated with the acquisition of products and services while maintaining the quality of said goods and the efficiency of operations.

This strategy has long been the most common procurement strategy out there.

Pierre Laprée, CPO at SpendHQ, a procurement software company, explains why that is the case.

Illustration: Veridion / Quote: SpendHQ

Indeed, year after year, study after study, the data tells the same story: cost saving should be procurement’s main concern.

For instance, The Hackett Group’s 2024 The CPO Agenda report reveals that CPOs’ number one priority for the year is improving their spend cost reduction, surpassing various other goals like ensuring supply chain continuity.

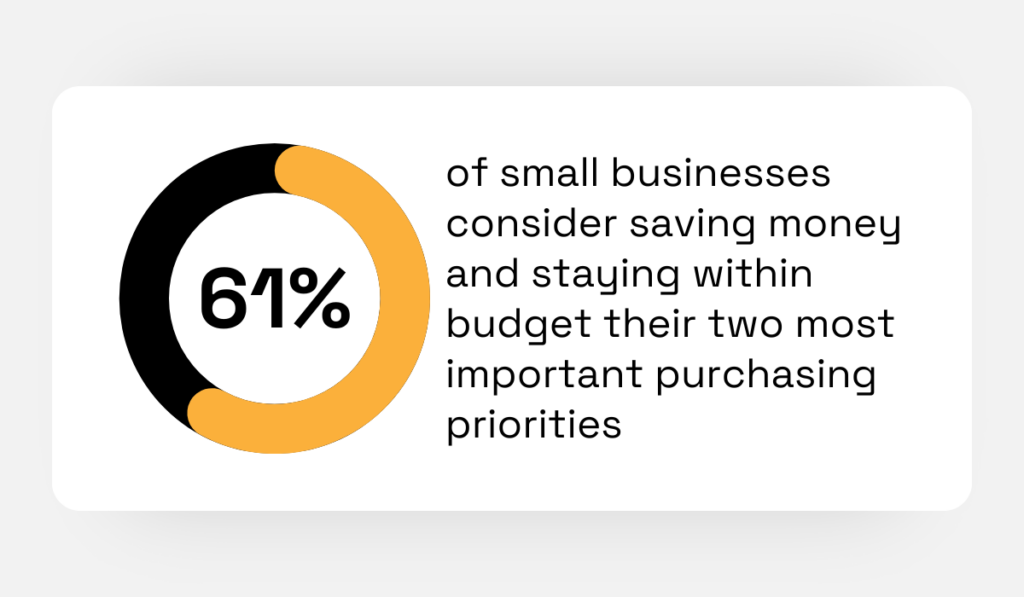

A 2023 Amazon Business survey reveals some interesting insights, too.

As it turns out, 61% of small businesses consider finding ways to save money and staying within budget their two most important purchasing priorities.

Illustration: Veridion / Data: Amazon Business

No wonder procurement professionals feel the pressure to maximize these savings.

But how do they achieve them, and what do cost reduction strategies typically entail?

Well, they are usually a mix of tactics, such as strategic sourcing, negotiations, process automation, and more.

Walmart, for example, diversified its supplier network to cut down the procurement costs.

In 2023, instead of depending solely on China, they started to import more from India, where the cost of importing was significantly lower.

As their Executive Vice President of Sourcing, Andrea Albright, points out, relying on a single supplier or area is quite limiting.

Illustration: Veridion / Quote: Reuters

Not only does it mean missing out on potential savings, but it also exposes you to significant risk.

But no matter which tactics you choose to include in your cost reduction plan, one thing is crucial for its success: staying well-informed.

Understanding your spend data, total cost of ownership (TCO), supplier performance, and market trends is an absolute must.

This information will direct you toward the most cost-effective decisions and pinpoint areas for improvement.

Paul Goydan, Senior Partner and Managing Director at The Boston Consulting Group adds tracking supplier price increases to that list as well.

Illustration: Veridion / Quote: Industry Dive

This can help you understand what’s fair and what to expect, in turn empowering you to negotiate better prices and avoid being taken advantage of.

Now, although cost reduction has been the most prominent strategy for a very long time now, CPOs are slowly starting to take a more strategic approach to purchasing and focus on long-term objectives.

This has brought many other procurement strategies into the spotlight.

Let’s explore what they are.

Risk management identifies and mitigates risks associated with the procurement process, all with the goal of protecting the company from financial loss, noncompliance, and other similar issues.

Given the increasing complexity of supply chains, such strategies are crucial for businesses to survive in today’s market.

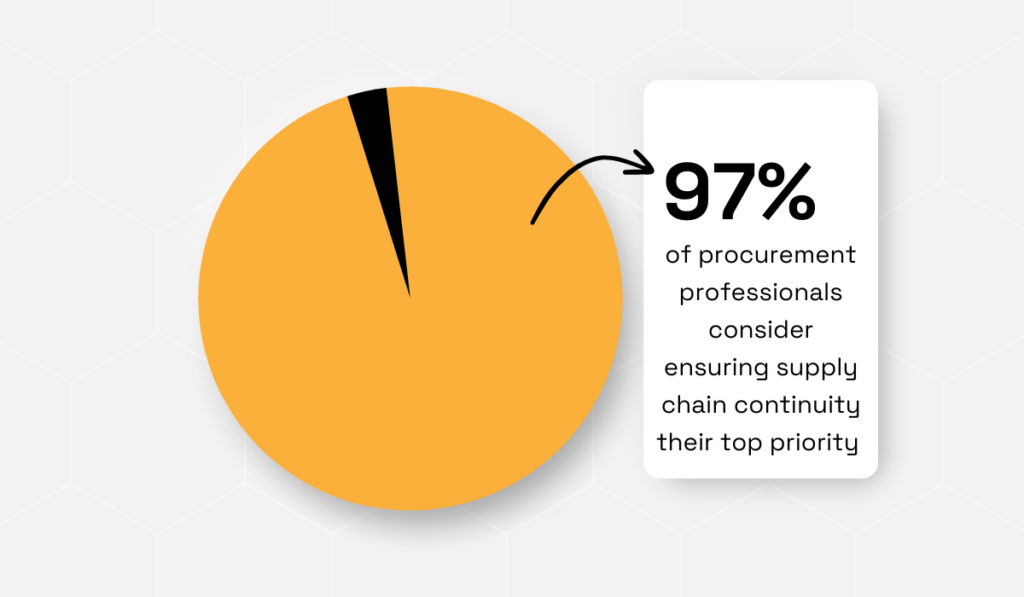

Perhaps it’s unsurprising, then, that 97% of CPOs consider ensuring supply chain continuity their top priority, according to a 2022 study by Ivalua.

Illustration: Veridion / Data: Ivalua

The lessons learned from the COVID-19 pandemic have made it crystal clear just how fragile supply chains can be and highlighted the importance of preparing for the unexpected.

That’s where risk management comes in.

Employing various measures—such as diversifying suppliers or conducting frequent audits—it ensures the necessary goods are procured with minimal disruption.

Procter & Gamble, for example, leverages technology and automation for this very purpose.

Over the past decades, they have heavily invested in e-commerce systems as well as data analytics tools, and the investment certainly paid off.

Their former CIO, Vittorio Cretella, elaborates.

Illustration: Veridion / Quote: Forbes

The tools help them analyze current market trends and conditions, along with their own performance, in order to optimize procurement decisions.

In turn, they know exactly what and how much to procure, minimizing the risk of overstocking and ensuring continuous customer satisfaction.

This brings us to the secret ingredient of a successful risk management strategy: being able to respond promptly to issues.

We’ve seen this with the P&G example, too.

If you can detect a potential problem early on, you’re left with enough time to do something about it and prevent it from getting worse.

But you don’t have to be a multinational consumer goods corporation with a huge tech budget to achieve this level of responsiveness.

There are plenty of affordable procurement-specific solutions available that’ll do the trick.

And chances are, you’re probably already using some of them.

For instance, sourcing enabler tools like Veridion can be incredibly efficient in detecting supplier risk.

Veridion keeps a vigilant eye on your supplier data, updating your Supplier Master Record (SMR) in real-time and alerting you if any risks, such as supplier bankruptcy, are detected.

Source: Veridion

You can then put your contingency plan into action and avoid larger problems, keeping your operations running smoothly.

And that’s precisely what effective risk management is all about.

Supplier optimization strategies prioritize developing long-term relationships with suppliers and boosting their performance to maximize the value they provide in terms of cost and quality.

Judging from recent research, these strategies are increasingly gaining traction.

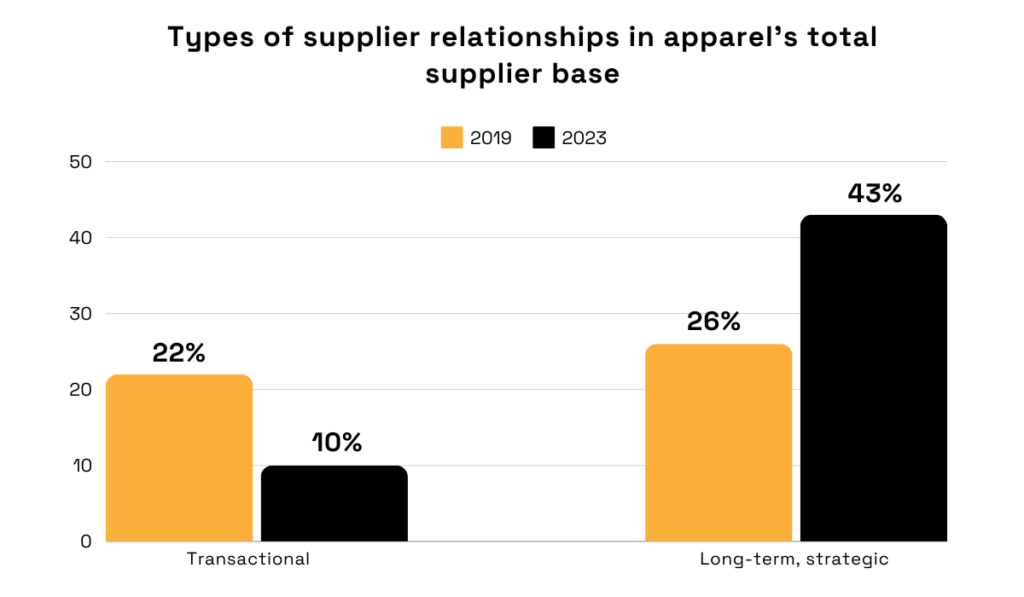

For example, a McKinsey survey of CPOs in the apparel industry shows that the amount of deeper relationships with suppliers has increased from 26% in 2019 to 43% in 2023.

At the same time, purely transactional relationships have declined from 22% to 10%.

Illustration: Veridion / Data: McKinsey&Company

This only goes to show that organizations are finally starting to realize just how valuable of an asset a strong supplier-buyer relationship can be.

They open the door to better pricing, as well as help mitigate supply chain risk.

Who wouldn’t want that?

But the question is, how exactly do you master supplier optimization?

Like with any other strategic initiative, there’s a range of tactics at your disposal.

Some businesses rigorously measure supplier performance using KPIs and detailed scorecards, while others implement thorough, targeted training programs.

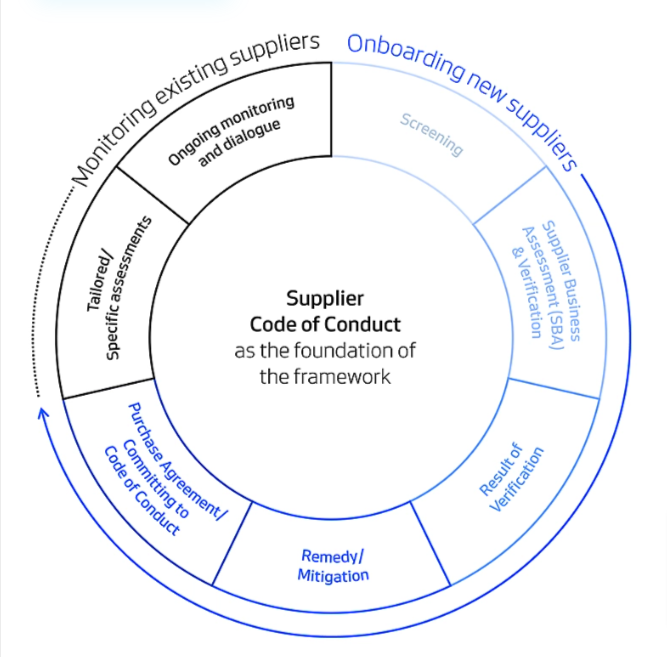

Vestas, the largest wind turbine manufacturer in the world, starts optimizing suppliers right from the onboarding process.

At the center of their strategy is the Supplier Code of Conduct, which outlines all the expectations suppliers need to meet and details every step of the onboarding process, ensuring complete alignment from the get-go.

You can see what this onboarding process looks like below.

Source: Vestas

Such thoroughness and clearly defined standards allow Vestas to work with only the most dependable partners and lay the groundwork for long-term collaboration.

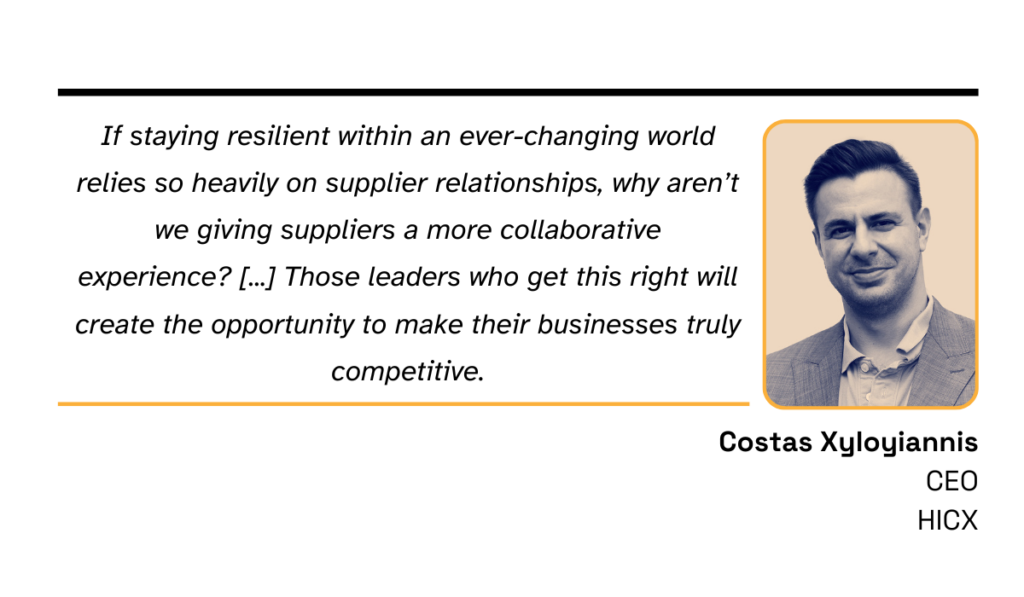

Now, if there’s one thing that guarantees the success of your supplier optimization strategy, it’s supplier involvement and communication.

This simple, yet often neglected element of supplier relationships ensures mutual understanding, promotes effective coordination, and makes problem resolution so much faster.

Costas Xyloyiannis, CEO of HICX, the supplier experience management platform, certainly seems to agree.

Illustration: Veridion / Quote: Procurement Magazine

So, be sure to clearly convey your expectations—just like they do at Vestas—as well as give and ask for feedback every once in a while.

This will help you transform your suppliers from vendors to strategic partners that shield your business from risks and fuel growth.

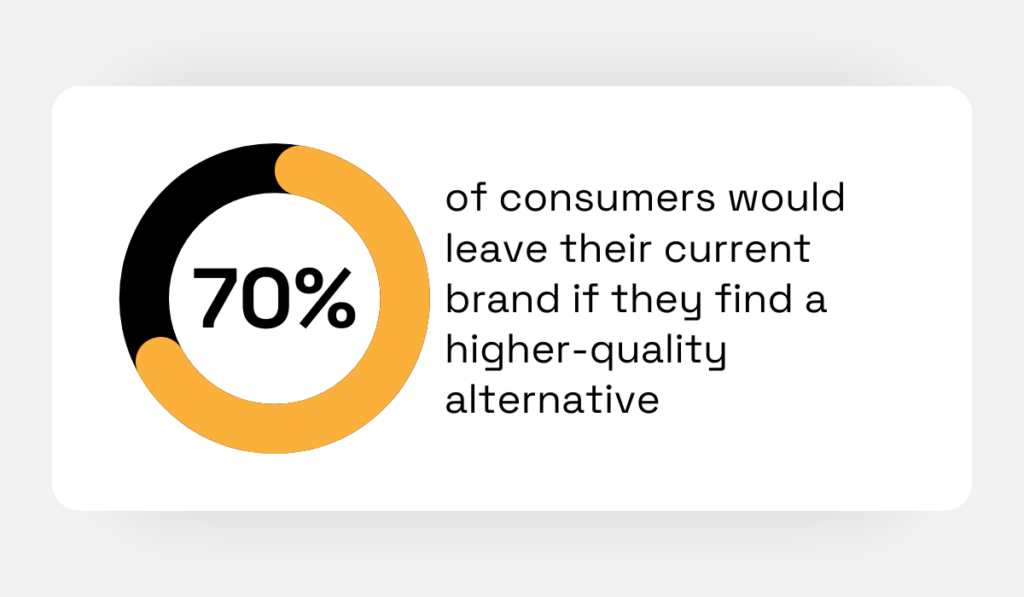

Total quality management (TQM) is aimed at assessing and managing the quality of goods and services you procure to ensure they adhere to specified standards and prevent purchase issues.

So, why should you care about this particular strategy?

Well, TQM has a large role to play in ensuring customer satisfaction and loyalty.

Did you know that, according to a 2024 Forbes Advisor study, 70% of consumers would switch brands for better product quality?

Illustration: Veridion / Data: Forbes Advisor

That’s right, quality matters. And TQM helps maintain it.

That’s why procurement departments often implement measures such as:

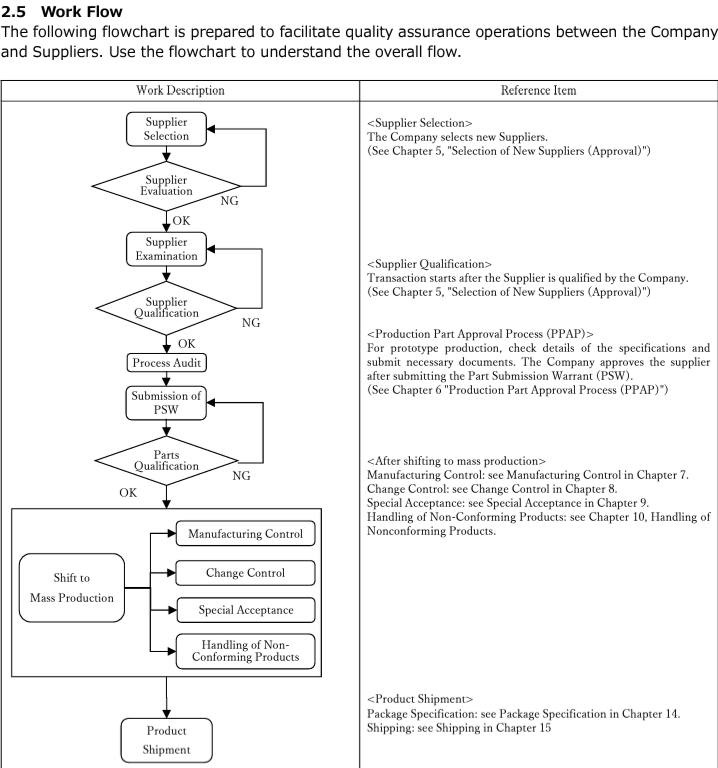

A good example of effective TQM implementation is MinebeaMitsumi, a Japanese multinational manufacturer of mechanical components and electronic devices.

Their website features a detailed Supplier Quality Assurance Manual outlining in great detail their quality assessment workflow, along with all the requirements their suppliers must meet.

Source: MinebeaMitsumi

With MinebeaMitsumi, there’s certainly no room for ambiguity when it comes to quality.

And they’re not alone: any company that’s serious about receiving the best product needs a similar document in its TQM toolkit.

So, to make your TQM strategy truly effective, you need to establish precise metrics that help monitor and gauge the quality of received products from the start.

Some relevant KPIs to consider include:

In a way, they act as an early warning system, alerting you to any dips in quality so you can address issues promptly—perhaps with supplier training or other corrective actions.

Remember, you need to be the one who notices the problem first, not your customers.

Integrating clear KPIs into your TQM will help you achieve just that, ensuring the highest quality standards and keeping customers happy.

Green purchasing strategies are all about buying eco-friendly products and reducing the overall environmental impact of the procurement process.

This is yet another strategy that has become increasingly important in ensuring customer satisfaction.

Emily Cromwell, Climate Change and Sustainability Lead for the Consumer Industry at Deloitte, explains that today’s consumers are more environmentally conscious than ever and expect businesses to follow suit.

Illustration: Veridion / Quote: Deloitte

Those who do so, in turn, enjoy benefits such as increased customer loyalty and a broader customer base.

Green purchasing strategies encompass all sorts of tactics: from developing “green” criteria that evaluate products based on factors such as recyclable content to working with ESG-compliant suppliers.

Take, for example, Scania Group, a vehicle manufacturing company.

In 2023, they started their own sustainable procurement initiative that aims for “100% green purchases of steel, batteries, aluminum and cast iron for its European operations by 2030.”

As their CEO Christian Levin says, this will be a real game-changer in the world of sustainable transport.

Illustration: Veridion / Quote: Scania

Supplier engagement and collaboration have a significant role in this initiative.

For instance, they partnered up with Northvolt, a Swedish battery developer:

“Scania and Northvolt have developed a battery cell specifically designed for heavy-duty transportation with world-class performance and a uniquely low carbon footprint.”

See?

With suppliers that see things your way, your green purchasing strategy can truly flourish.

But here’s the catch: the strategy must align with broader company goals to be effective.

So, if a company prioritizes financial performance, your strategy should support, and not clash with this objective.

This could mean driving cost savings through energy efficiency or boosting sales by enhancing the brand’s eco-friendly image.

As Matias Pollmann-Larsen aptly points out, business success and sustainability are not at odds.

Illustration: Veridion / Quote: Procurement Magazine

In fact, they can and will complement each other beautifully, but only with a thoughtfully designed green purchasing strategy.

Just like regular sourcing, global sourcing aims to procure the goods and services a company needs in the most cost-effective and efficient manner.

The key difference?

Global sourcing taps into the worldwide market, rather than limiting itself to domestic suppliers.

This global reach offers businesses access to a broader range of vendors, increasing opportunities for cost savings, discovering new products, and ensuring higher product quality.

As our CEO, Florin Tufan, says, gone are the days of being limited to just a few suppliers:

“If you had three suppliers for one highly important thing, you’d much rather spend a lot of time strengthening that relationship and putting better protection in place. There was no easy way to ask about others and question whether you were working with the right ones while finding out if you had enough resiliency. Now, you want to work with the best ones so that you’re covered and get on with the work no matter what.”

Thanks to global sourcing, you now have the freedom to collaborate with anyone you want.

Now, implementing global sourcing strategies takes a lot of work.

You first need to conduct thorough research to identify potential international partners and then analyze global market trends, currency fluctuations, and geopolitical factors.

And let’s not forget about assessing the cost-benefit of sourcing from different regions.

Yet, the payoff is significant.

Mission Produce, the global leader in fresh avocado distribution, can attest to that.

Working with suppliers across 25 countries allows them to keep delivering the product their partners and customers expect, says Diana McClean, their Director of Marketing and Communications.

Illustration: Veridion / Quote: Blue Book

Regardless of the season, bad weather, or local disruptions, everybody knows that Mission Produce will deliver, every single time.

Considering how complex global sourcing can be, the key factor for its success is the ability to find reliable suppliers quickly and easily.

How do you achieve that?

You guessed it: technology.

Big data platforms like Veridion let you tap into their extensive global database of millions upon millions of suppliers and find partners that perfectly fit your needs.

Using Veridion’s Search API, you define criteria that are relevant to you, and the system quickly presents you with a shortlist of potential suppliers.

Source: Veridion

Just how quick is it, you ask?

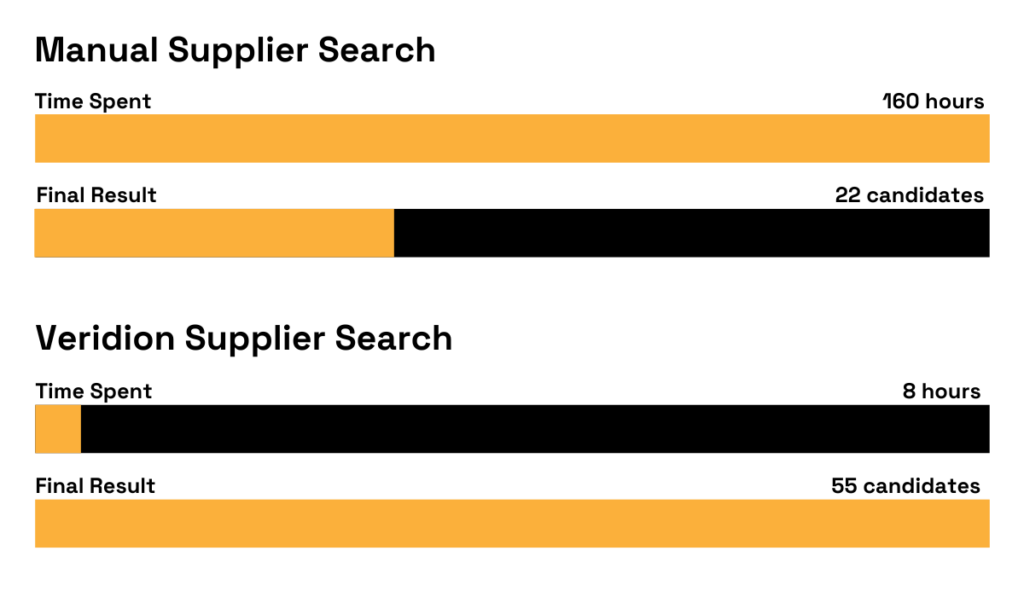

Take a look at the image below.

Source: Veridion

This graph compares supplier discovery done manually by two full-time employees to a Veridion-powered search by one of our data analysts.

As you can see, with Veridion, you get much better results in only a fraction of the time.

It’s the perfect tool for anyone wanting to take their global sourcing strategy to the next level.

At the end of the day, procurement is about so much more than just cutting costs.

It can contribute to the company’s resilience or sustainability goals, and even help boost its reputation—all with the right strategy in place.

With a well-thought-out strategy, you not only deliver great financial results, but can also position the procurement function as a strategic partner to the company, bringing real, long-term benefits to the table.

After all, isn’t that the essence of being a true procurement leader