Procurement Strategy Matrix: Everything You Need to Know

Over many decades, various tools have been developed to make procurement more strategic, efficient, and capable of yielding better results.

One such tool is the procurement strategy matrix.

In this article, we’ll dive into everything you need to know about the matrix, from its components to its applications, as well as some limitations.

By the end, you’ll be more than well-equipped to categorize items with precision using this tool and develop your own winning procurement strategies.

Let’s start with the basics.

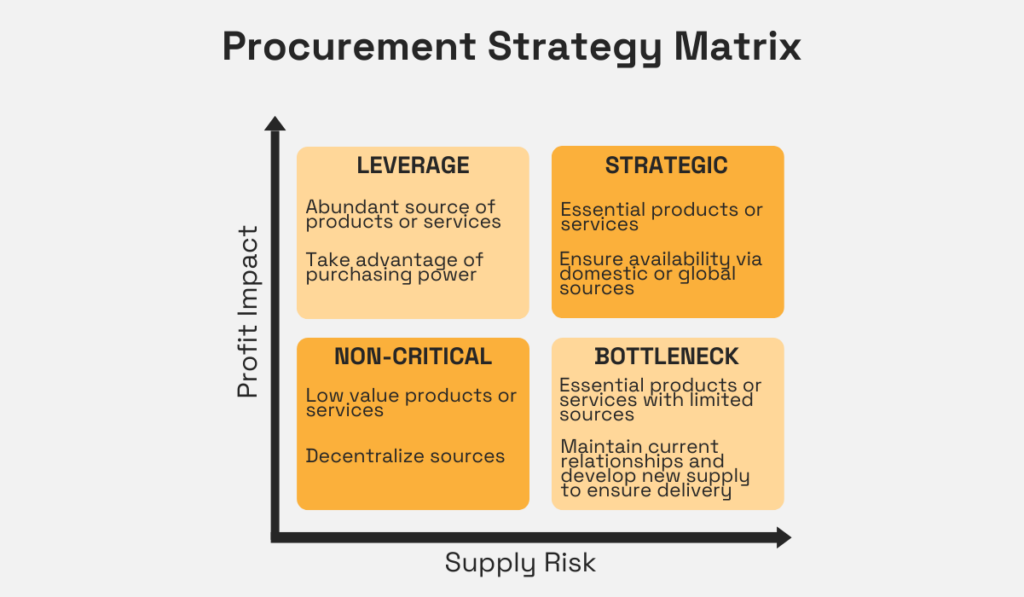

Developed in 1983 by Peter Kraljic, the procurement strategy matrix (or Kraljic matrix) is a tool used by procurement professionals to develop strategies for sourcing various goods based on their profit impact and supply risk.

It consists of four categories or quadrants, which you can see outlined below.

Source: Veridion

Now, let’s break each of them down.

Non-critical, or routine items are both low in impact on profit and low in supply risk.

Think office supplies, maintenance, repair, and operations (MRO) items, or various consumables.

These items don’t have a considerable influence on the company’s overall profitability and are readily available from many different suppliers.

This means there’s minimal risk involved in their purchasing.

However, the procurement of these goods still needs to be properly managed.

This isn’t because their absence would cause significant operational inefficiency, but because the handling costs can easily accumulate if you’re not careful enough.

Sure, that $30 case of paper might not seem like a huge financial investment, but the hidden administrative expenses of ordering, receiving, and processing payments can quickly add up, especially if done multiple times a year.

Ultimately, the process of ordering paper ends up costing more than the paper itself.

That’s why strategies for procuring routine items usually prioritize boosting process efficiency and cost savings, mostly through automation.

Miguel Galeti, Procurement and Commercial Operations Director at an HR services company Em Transição de Carreira, agrees that implementing various procurement software is definitely the way to go in this context.

Illustration: Veridion / Quote: LinkedIn

They help streamline many cumbersome, yet critical processes, saving you both time and money.

This way, you free up the procurement team to focus on more strategic, high-impact activities, while simultaneously ensuring these products are always available when you need them.

Leverage items have a high impact on the bottom line but, due to the abundance of supply, there’s minimal risk involved in their sourcing.

Items that belong in this category are commodities such as steel, aluminum, or basic chemicals that are all necessary for production, but can be sourced from multiple suppliers.

Here, you’ll find the biggest opportunities for cost savings.

In fact, this quadrant is often dubbed a “buyer’s market” because, essentially, the buyers hold all the power and dictate the terms.

When procuring these items, companies use strategies like bulk purchasing, competitive bidding, or switching suppliers to secure the best possible prices.

Historically, very aggressive negotiations were common in this context, too, although this is now slowly changing.

More and more procurement professionals are turning to strategic procurement and sourcing, moving away from securing quick, one-sided wins and trying to unlock more long-term value.

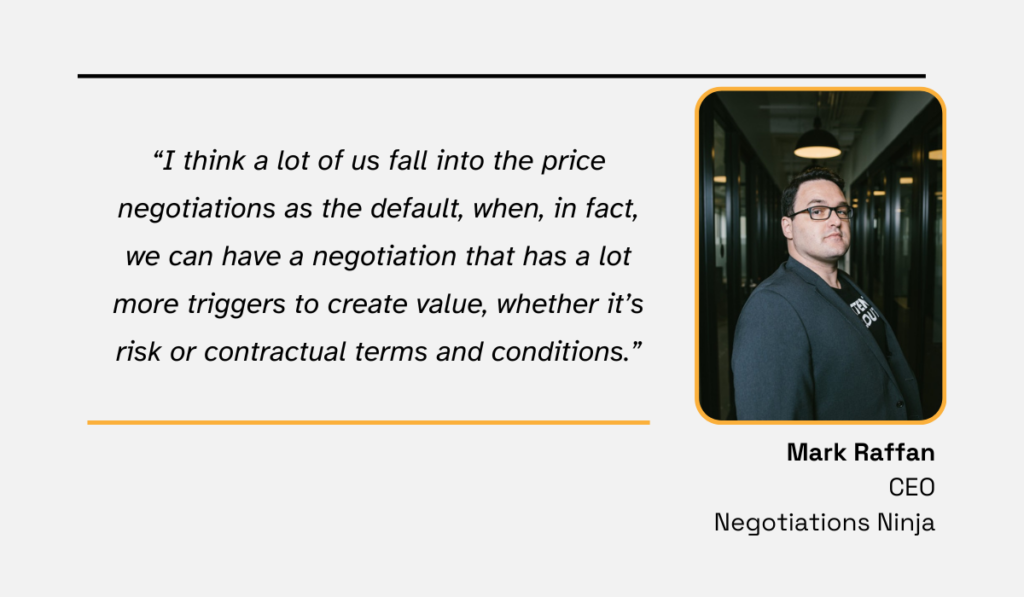

And negotiation is a great way to achieve that added value, points out Mark Raffan, CEO of the negotiation and communication training company, Negotiations Ninja.

Illustration: Veridion / Quote: Art of Procurement

Of course, procurement teams still leverage their power when buying these items, but now, they have adopted a much more strategic mindset.

It isn’t just about finding ways to save money anymore.

Rather, it’s about extracting every ounce of value from buyer-supplier relationships—in a way that benefits both parties involved.

Bottleneck items, in contrast, are where the suppliers have the upper hand.

These items have a low impact on profit, but their risk is high due to limited sources of supply.

Consequently, this quadrant is prone to frequent price increases and can take up more of the buyers’ time than any other category—hence the name “bottleneck.”

When procuring such goods, organizations usually focus on two things:

Thanks to global sourcing, the latter tactic is increasingly gaining traction.

Sjoerd Goedhart, Owner of Goedhart Interim Management & Consultancy, explains why that might be.

Illustration: Veridion / Quote: Procurement Tactics

Basically, procurement departments can now use advanced, AI-powered platforms like Veridion to browse suppliers worldwide and potentially unlock better prices and product quality.

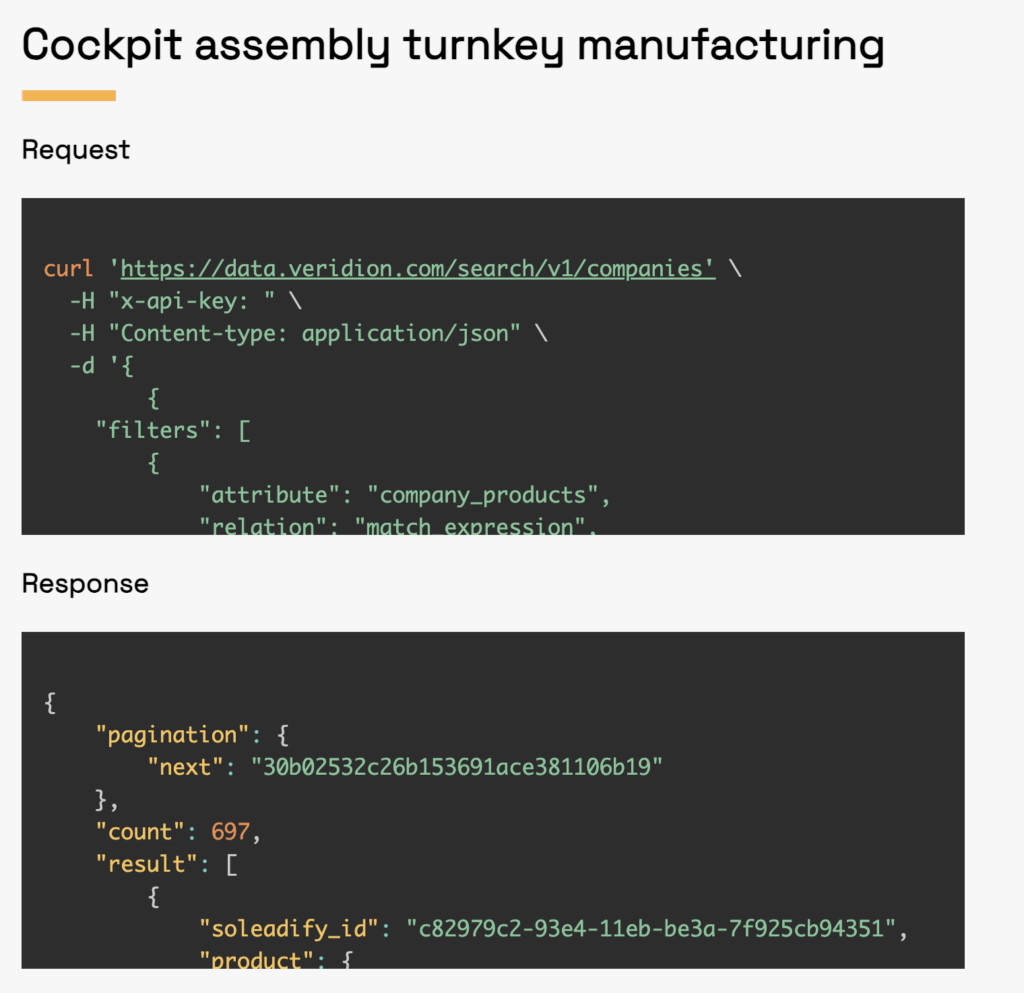

With Veridion’s Search API, users can filter suppliers based on their own criteria, from general information like location to specific ESG metrics, until they find exactly what they’re looking for.

Source: Veridion

No need to rely only on local vendors anymore!

This way, they can expand their supplier base quickly and easily, as well as reduce dependency on certain bottleneck suppliers.

Strategic or critical items have a high impact on the bottom line and involve high supply risk.

They are the lifeblood of your operations: crucial for success but often challenging to come by, especially because they have no suitable substitutes.

To ensure the successful procurement of such goods, having reliable partners is a must, no two ways about that.

These partners will always deliver and maybe even prioritize you during shortages, ensuring a consistent, risk-free supply of those strategic items.

This is why critical item purchasing strategies frequently focus on supplier-buyer collaboration.

Take Jabil, a multinational manufacturing company, for example.

Their relationship with Vishay, a supplier of passive components and semiconductors, perfectly illustrates the type of partnership you should aim for.

As per Jabil’s own website:

“Vishay advises Jabil on where we may want to upgrade components to provide lower cost and more readily available components. This helps us weather disruptions and better serve our customers when the market tightens up, like in the case of component shortages and COVID-19.”

When you have partners like that, you definitely never have to worry about running out of critical components.

Now that we’re a bit more familiar with the matrix itself, let’s explore some of its applications and use cases.

The procurement strategy matrix analyzes risks associated with items in every quadrant and helps develop appropriate risk mitigation strategies for each of them.

For non-critical items, for instance, this can involve automating processes to minimize costs and time spent on ordering, receiving, and processing orders.

CPO Karl Poulsen explains how this is done in Hiscox, an insurance company he works for:

“AI can be used to cut down some of the manual processes that exist in procurement. One example is to flag that there is a difference between the order and what has been received. You could then build a bit of code that says, ‘Well, we only ordered 10. If the supplier sent us 15 or something, maybe that’s their fault.”

Or, for bottleneck and critical items, the strategy might include diversifying suppliers to prevent shortages that could cause operational inefficiencies and delays.

Vanilla is an excellent example of an item where such a strategy could be quite effective.

As a staple for many food and beverage businesses, running out of vanilla would spell a major disaster.

However, Prossy Tumushabe, Executive Director of the Association of Vanilla Exporters in Uganda Limited, explains that through diversification, such risk can be significantly decreased.

Illustration: Veridion / Quote: Supply Chain Dive

The bottom line?

Any risk management strategy in procurement relies heavily on the insights gained from the matrix.

It helps you diagnose possible risks within each category, along with their severity and probability of occurrence.

As a result, you become much better equipped to come up with successful contingency plans and keep your supply chain disruption-free.

The Kraljic matrix doesn’t only help minimize risks, though.

It also aids in developing effective procurement strategies tailored to a company’s specific needs and the criticality of the items it procures.

For example, here’s how Marijn Overvest, CEO and Founder of Procurement Tactics, a company providing training for procurement professionals, used the matrix for this very purpose:

“I focused on measuring our dependence on suppliers along the horizontal axis, considering factors such as product criticality and availability of alternatives. This helped us tailor negotiation strategies based on supplier dependence and margin contribution, optimizing our procurement efforts for efficiency and value.”

Essentially, the matrix gives you insights into the criticality of each item, enabling you to adjust your strategies accordingly.

This entails allocating more resources to critical items, nurturing relationships with suppliers that add more long-term value, and, of course, creating contingency plans for those risk-prone categories.

That way, you can ensure critical products and services are always in supply, while non-critical ones don’t cause budget overruns and unnecessary operational disruptions.

The matrix helps you gauge your purchasing power related to each quadrant, allowing you to fine-tune your procurement strategy for the best financial outcomes.

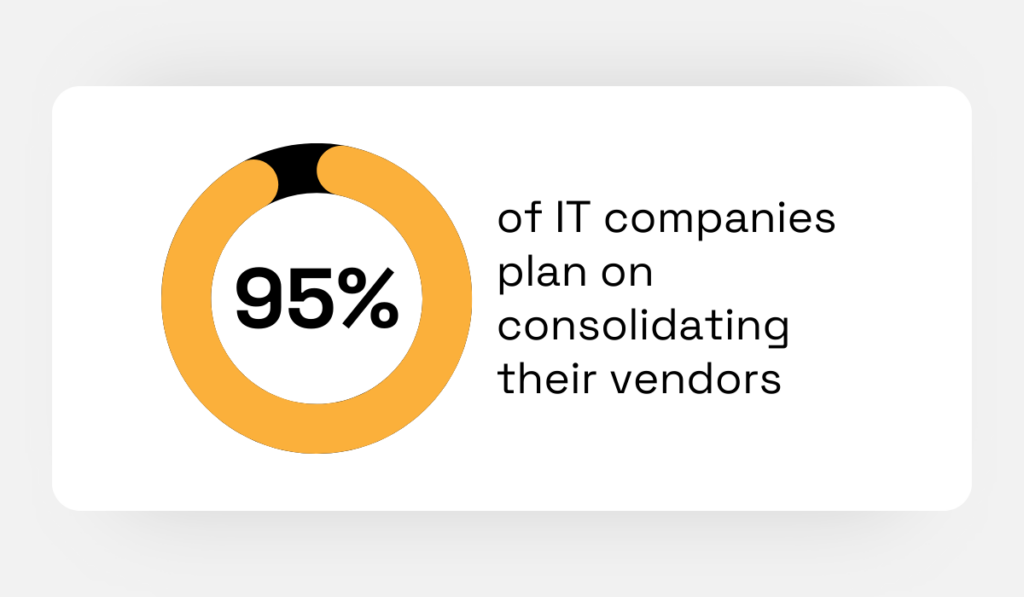

For instance, for items where you have high purchasing power, you might achieve direct cost savings through negotiations or by consolidating purchases with fewer suppliers.

After all, suppliers are much more inclined to offer a discount for larger orders, right?

According to CIO research, this tactic has become something of a go-to in the IT sector, with 95% of IT purchasing executives planning on employing this approach.

Illustration: Veridion / Data: CIO

It makes sense, really.

Not only does this give them more purchasing power, but also significantly simplifies supplier management.

Now, on the flip side, for categories where your purchasing power is low, chasing significant cost savings isn’t always possible.

So, instead, you might want to focus on minimizing supply chain disruptions and associated financial risks.

This can involve securing long-term contracts, coming up with robust contingency plans, and strengthening supplier relationships to increase their reliability.

Overall, in procurement, there are countless different ways to reduce costs and boost profits.

But without the matrix, you simply can’t know which way is the right one for each particular item category.

Let’s not forget that the matrix was developed some 40 years ago.

Since then, procurement has changed drastically, so it’s only natural that the matrix will display certain limitations.

Let’s explore what those are.

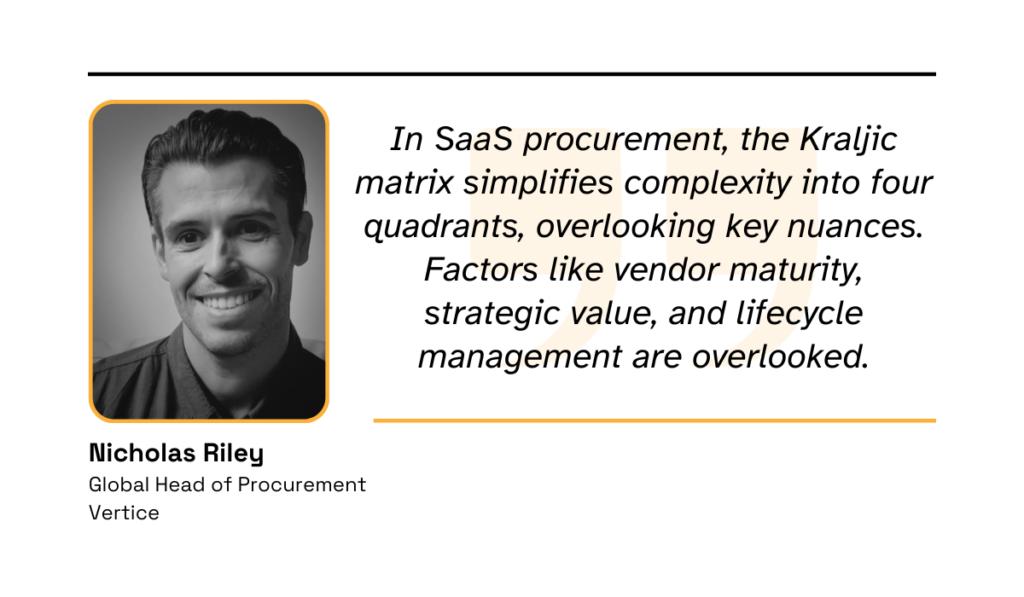

Reducing category analysis to only two dimensions—profit impact and supply risk—isn’t always enough to capture the complexity and nuances present in real-life purchasing.

According to Nicholas Riley, Global Head of Procurement at a spend optimization platform Vertice, there are many other factors procurement professionals need to take into account.

Illustration: Veridion / Quote: LinkedIn

And this is true for any sector, not just SaaS.

Elements such as product quality, supplier’s innovation potential, regulatory requirements, and ESG criteria, all have a role to play in modern-day procurement decision-making.

So, to fix this problem, consider revising and updating the matrix every once in a while.

You can add new dimensions to your matrix or even create subcategories within each quadrant to align better with your own specific needs and circumstances.

At the end of the day, this tool was designed to help you develop effective procurement strategies.

What good does it do if it can’t be adapted to actual, real-life situations?

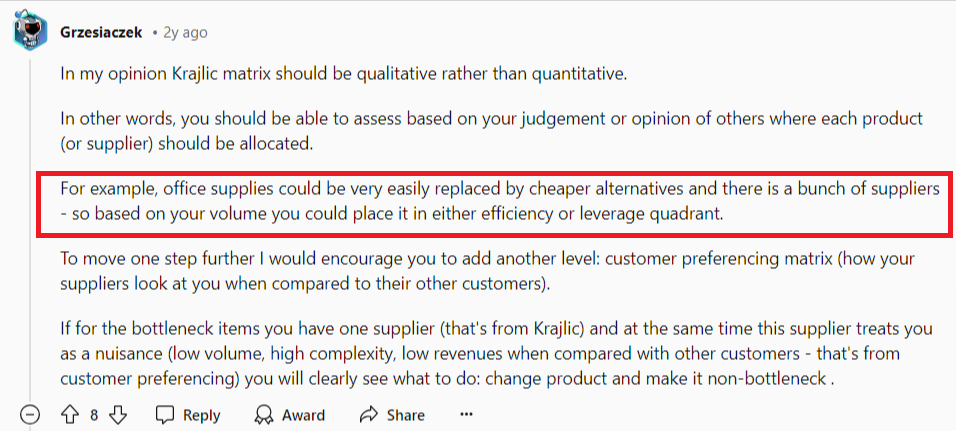

The matrix relies heavily on the qualitative assessment of the people using it.

This means that each individual may look at the category criteria through their own lens, leading to inconsistent and overly subjective categorization of items.

This Reddit user shares an example that perfectly illustrates this point.

Source: Reddit

And if the team cannot agree on the category an item belongs to, coming up with a successful procurement strategy becomes extremely difficult, if not downright impossible.

But, how can you increase objectivity then?

Try defining clear, measurable KPIs for each dimension.

For instance, for supply risk, focus on suppliers’ financial health, price fluctuations for key materials, or the percentage of suppliers meeting all regulatory standards.

For profit impact, track the contribution of procured items to overall revenue, or the number of quality-related issues and returns.

Although some degree of subjectivity is inevitable no matter what, this will provide a standardized framework for evaluating suppliers across different categories.

Having to focus on concrete, consistent data points instead of subjective opinions will help your team stay as objective as possible.

The matrix provides a rather static analysis of purchasing portfolios, failing to account for frequent changes in market dynamics.

Factors such as fluctuating customer demand, new technologies, and geopolitical events can all significantly impact businesses.

Yet, the matrix categorizes items without considering any of these changes.

This can leave procurement professionals unable to respond to these shifts quickly enough, in turn exposing companies to all sorts of risks.

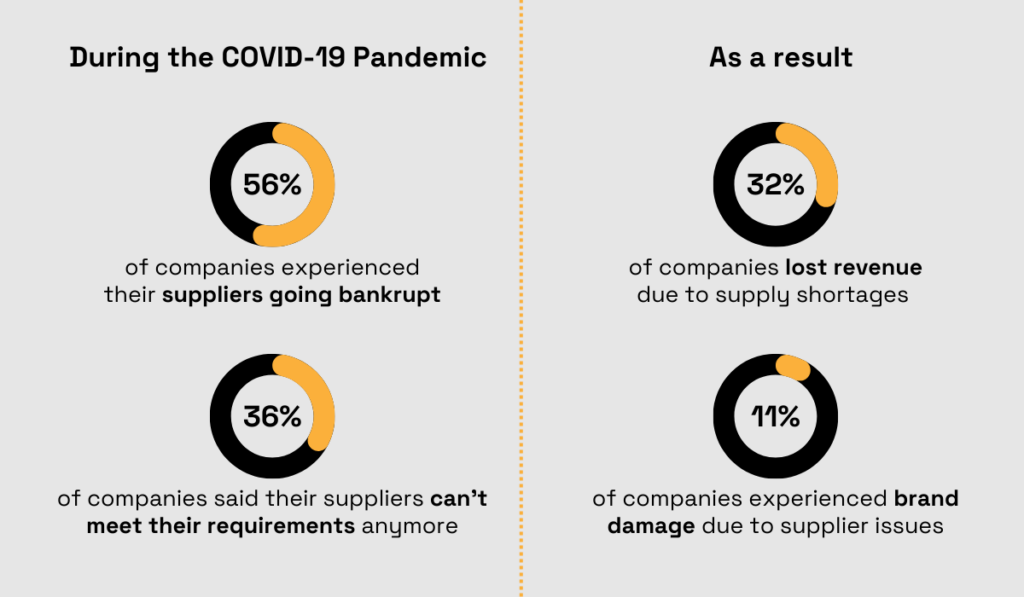

Those who witnessed firsthand the COVID-19 pandemic’s effect on the supply chain, know that even low-risk suppliers can turn into high-risk ones practically overnight.

Surveys reveal that many businesses experienced supplier bankruptcies or unmet requirements during these times, leading to revenue loss or brand damage.

Illustration: Veridion / Data: Deloitte

This only goes to show how important it is to stay on top of the changes in market conditions.

Because of that, performing analysis using the procurement strategy matrix shouldn’t be considered a one-time task.

Instead, try to establish a schedule for periodic reassessment of each item using the latest market intelligence to ensure your strategies stay up-to-date and agile.

All in all, despite its limitations, the Kraljic matrix can still be a highly valuable tool for developing efficient and cost-effective procurement strategies.

Its true strength lies in its adaptability—you can customize and expand it to fit your unique needs and evolving market conditions.

This flexibility allows you to more precisely categorize various items and develop tailored action plans for their procurement, helping you dodge supply chain risks and boost profitability.

So, if you haven’t already, give this tool a try.

It just might surprise you how effective it can be.