What is Supplier Lifecycle Management?

Key Takeaways:

Supplier lifecycle management is more than a process.

It’s a strategy that helps procurement teams manage each supplier relationship in a way that maximizes value for the entire organization.

From onboarding and segmentation to information and performance management, every step matters.

In this guide, we’ll explore how to master the full lifecycle, and drive cost savings, innovation, and overall success.

Eager to counter supplier risks and unlock new opportunities?

Let’s jump right into it.

Supplier lifecycle management (SLM) is a process that covers all aspects of a supplier’s engagement with the organization.

It involves a range of activities which help organizations optimize supplier relationships to get the most value out of them while mitigating emerging risks.

In the video below, you can see the essential parts of supplier lifecycle management:

Source: MeRLIN Sourcing on Youtube

If this sounds a lot like supplier relationship management (SRM), there’s a good reason why.

Both processes focus on relationship-building and overall supplier impact to help organizations prioritize the most impactful partnerships and address any issues proactively.

However, SLM is a broader concept.

As the name implies, it spans the entire supplier lifecycle, from initial onboarding to offboarding, and includes everything in between that will impact either contract renewal or termination.

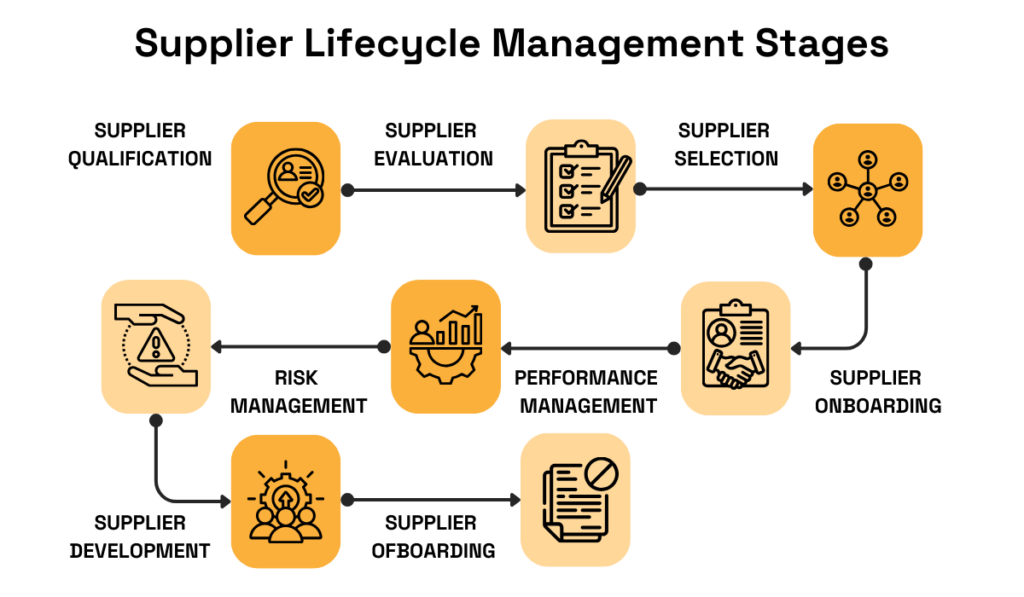

Keep in mind that there are different opinions about where lifecycle management begins and how the key processes are best grouped together.

Depending on the source, the number of distinct stages in SLM can range from five to eight, with many experts identifying supplier discovery and selection as the critical starting point.

Source: Veridion

Moreover, supplier development is sometimes used interchangeably with relationship management.

With that in mind, let’s break down the six most frequently mentioned stages:

| Onboarding | Integrating new suppliers, aligning expectations, and setting up communication channels. |

| Segmentation | Categorizing suppliers into different priority segments based on key factors like spend, risk, or strategic importance. |

| Performance Management | Evaluating supplier output against agreed KPIs to meet quality standards and ensure compliance. |

| Risk Management | Ongoing monitoring, analyzing, and mitigating supplier-related risks. |

| Development | Improving supplier capabilities, re-aligning and/or addressing gaps. |

| Offboarding | Terminating contracts and removing supplier’s access to your systems, data, and infrastructure. |

Now that we’ve established the basics, it’s time to explore how supplier lifecycle management can benefit your organization.

Besides giving organizations more control over their supplier relationships, robust SLM practices carry additional advantages.

Supplier lifecycle management creates a strong foundation for businesses to evaluate both their existing supplier base and potential additions.

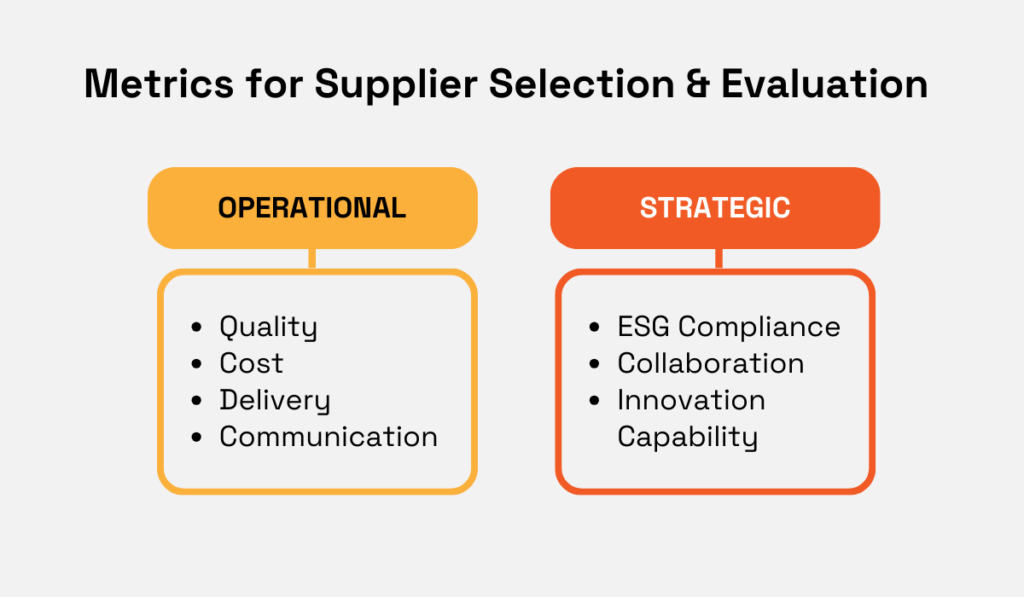

In a nutshell, the SLM provides an effective supplier selection framework by incorporating several elements, including structured criteria that go beyond cost, quality, and compliance.

Source: Veridion

If you’re wondering how this is any different from regular selection, the answer is consistency and level of detail.

Supplier lifecycle management leverages real-time and historical data, enabling you to identify both the operational excellence and strategic, long-term value of each supplier.

For example, an organization using SLM would rely on detailed selection scorecards and risk assessment frameworks to shortlist the best supplier profiles.

On the other hand, an organization that doesn’t invest in SLM is more likely to rely on incomplete and outdated information, creating an unrealistic picture of the supplier’s capabilities.

The evaluation process itself is less standardized, which means that the criteria aren’t always applied equally across all suppliers.

This can easily lead to oversights and biased decision-making.

All in all, supplier lifecycle management offers a structured approach that enables smarter decisions for selecting suppliers.

Comprehensive supplier lifecycle management enables businesses to discover and make full use of cost-saving opportunities.

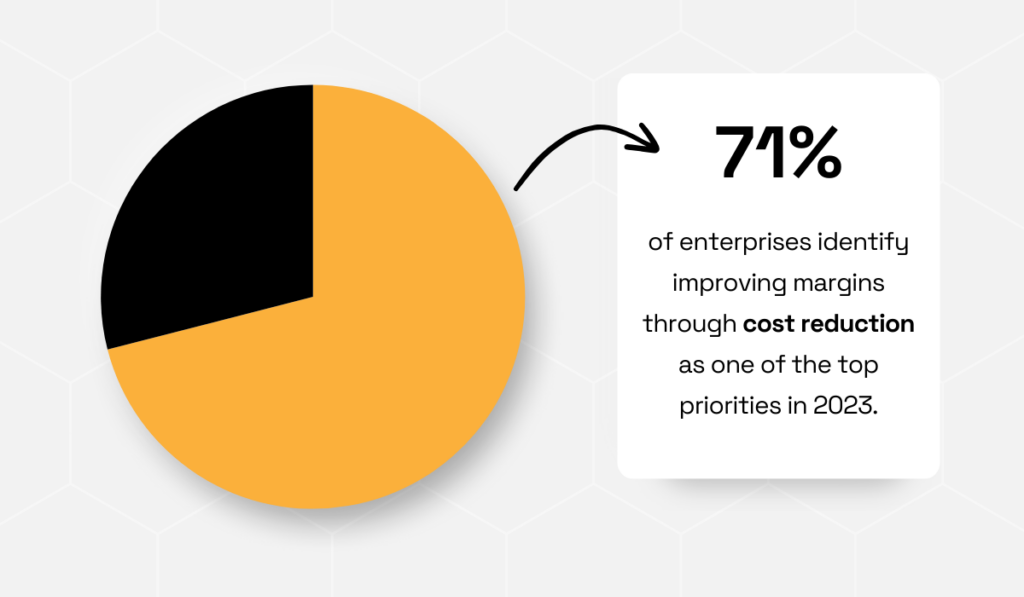

Cutting costs is a perpetual priority for organizations of all sizes and profiles, and Deloitte’s global CPO survey confirms this once again.

Namely, 71% of surveyed procurement leaders identified cost reduction as a top priority in 2023.

Illustration: Veridion / Data: Deloitte

The CPOs cost reduction strategies will inevitably differ, but there’s a strong case for incorporating supplier lifecycle management in them.

SLM helps reduce procurement costs and uncover savings by identifying supply chain inefficiencies and helping organizations optimize resources.

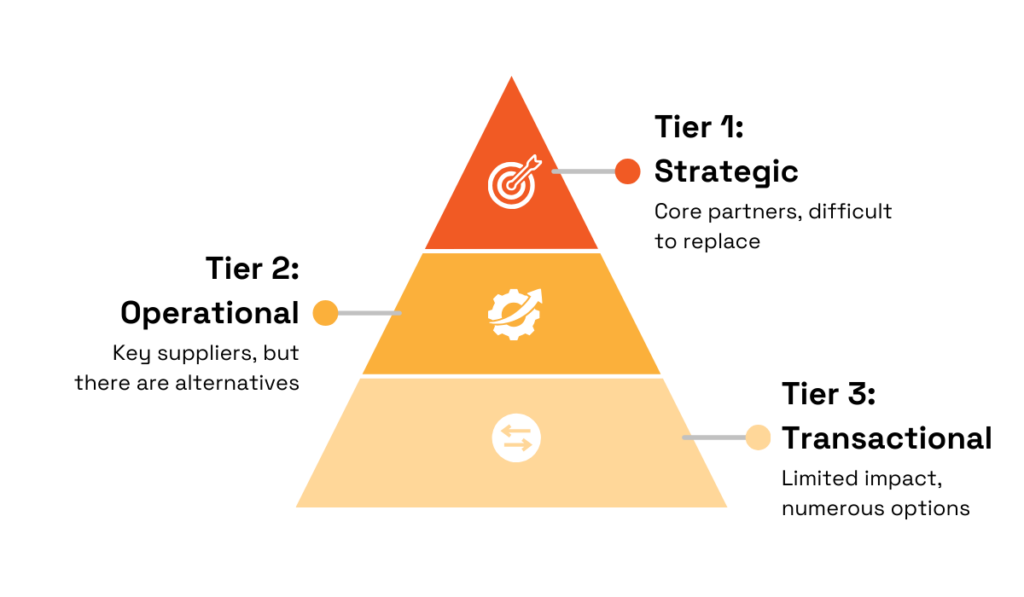

For example, this can be done by introducing a simple supplier segmentation framework to determine which relationships are crucial to your business, as opposed to merely transactional.

The pyramid method is one of the ways to do that.

Source: Veridion

This approach defines very broad supplier segments, but it helps guide contract negotiations and ensure you won’t be wasting resources on suppliers with minimal impact.

Of course, most of the inefficiencies are uncovered through proactive supplier performance monitoring.

SLM relies on several essential metrics to objectively evaluate and rank suppliers based on their performance, ensuring your decisions are data-driven and fully aligned with priorities.

By doing so, you can quickly identify cost-saving opportunities.

By integrating supplier lifecycle management processes, businesses can flag potential supplier-related risks very early in the process.

Financial instability or non-compliance are among the common procurement risks, and mitigating them on time is critical when considering how public and damaging they can be.

The fast fashion giant Shein experienced this firsthand after uncovering cases of child labor among suppliers.

Source: Guardian

Although Shein came forward with these cases, it’s safe to say that the episode will put another dent in its already shaky reputation.

Luckily, avoiding these and similar scenarios is entirely possible.

SLM is rooted in robust supplier risk management and promotes both strict evaluation and regular assessments that are essential for preventing reputational and financial harm.

In addition to establishing strong frameworks, managing suppliers builds trust and strengthens ongoing relationships.

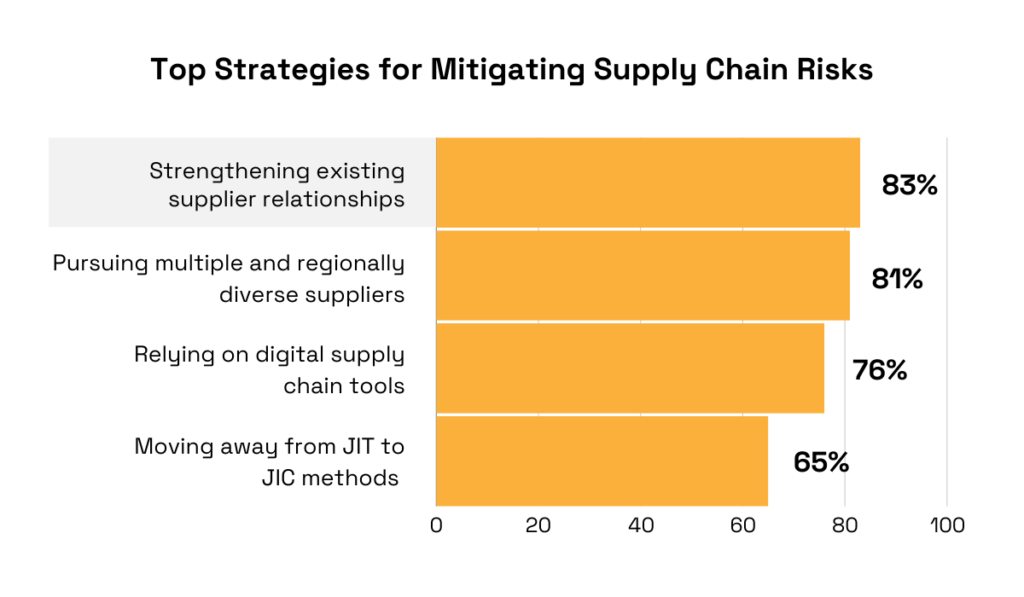

This is particularly important since research by Deloitte revealed that strengthening supplier relationships is the top strategy for mitigating supply chain risks.

Illustration: Veridion / Data: Deloitte

The surveyed executives highlighted that relationship management skills become critical in volatile environments, enabling organizations and suppliers to work together on adjusting strategies and managing costs.

To sum up, SLM’s benefits go beyond operational efficiency, and into active mitigation of key supplier-related risks.

For all its benefits, supplier lifecycle management is not without its challenges.

In this section, we’ll be zooming into three of them.

Data quality quickly becomes a cause for concern even for companies who don’t manage that many suppliers.

Outdated, inconsistent, or simply inaccurate data complicates supplier evaluations, which in turn impacts decision-making.

What’s worse is that organizations don’t always realize they’re relying on poor-quality data.

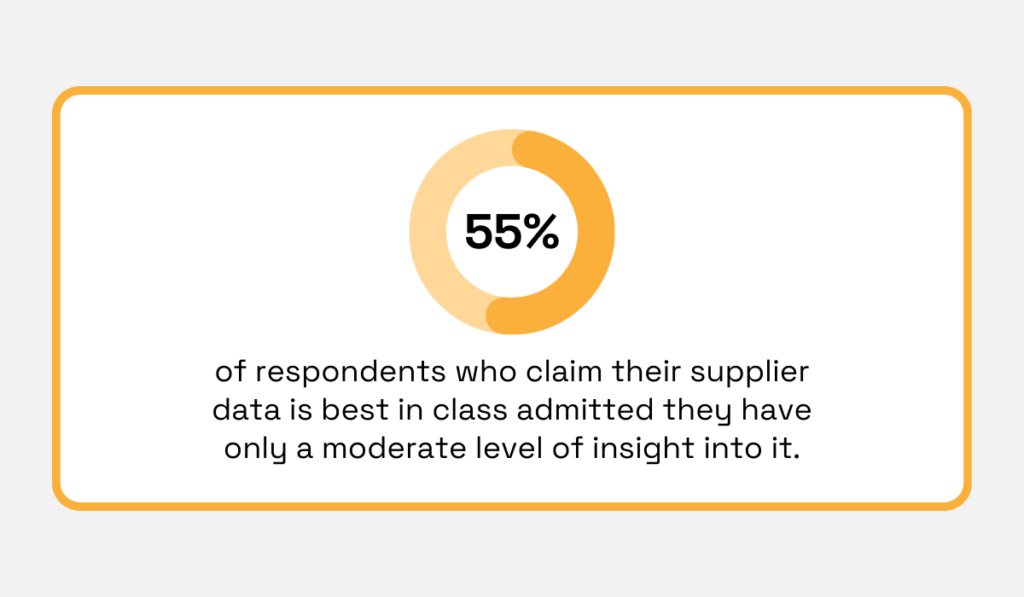

In fact, a recent study by HICX shows that over half of respondents have only a moderate level of insight into their data.

Illustration: Veridion / Data: HICX

When organizations lack visibility and oversight, it’s hard to assess the quality of their data.

As a result, they often assume there are no issues simply because they can’t see them.

Omera Khan, a leader in supply chain risk management, warns that these blind spots come with serious consequences.

Illustration: Veridion / Quote: HICX

Beyond harming performance, poor supplier data management exposes organizations to risks like fraud, non-compliance, and other vulnerabilities.

The aforementioned report by HICX highlights that procurement teams collect lots of data as part of the due diligence process.

However, the problems start when data is stored in isolated legacy systems or Excel sheets, which makes it difficult to use or update supplier data.

One way for businesses to overcome these challenges is by investing in supplier performance management software like Supplios which has automated tracking and reporting features.

Source: Supplios

SLM processes depend on accurate data, and overcoming data challenges is essential for building resilient and efficient supplier relationships.

Adopting SLM processes or related technologies requires stakeholder buy-in, but getting it may be challenging.

Major changes tend to create resistance and supplier lifecycle management is no different.

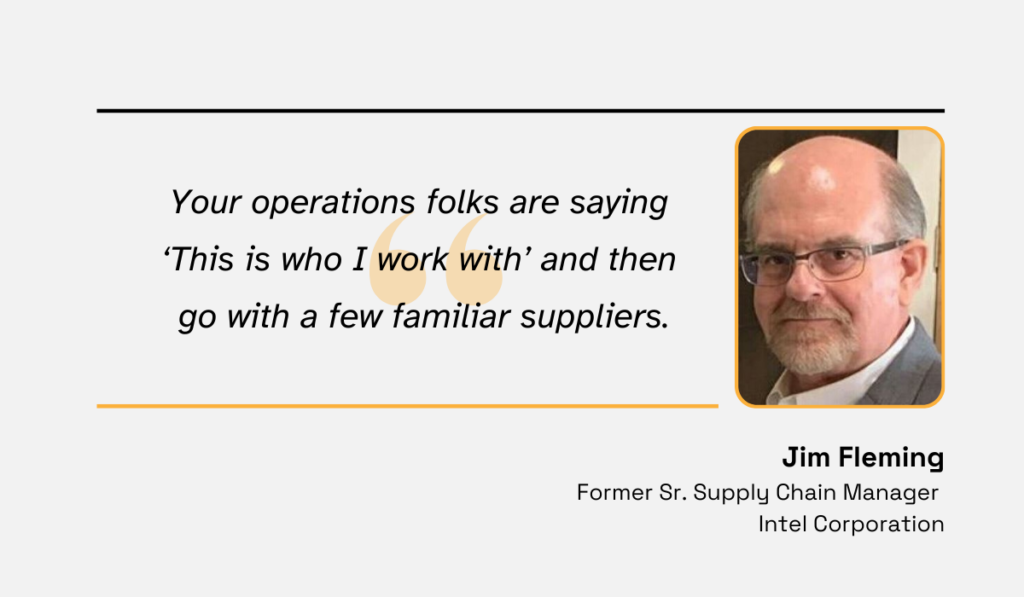

Jim Fleming, a senior associate at the Institute for Supply Management and former supply chain manager at Intel, explains that most stakeholders find it easier to stick with what they know.

Illustration: Veridion / Quote: ISM World

In other words, changing old mindsets and habits is grueling work, even when there’s no active resistance.

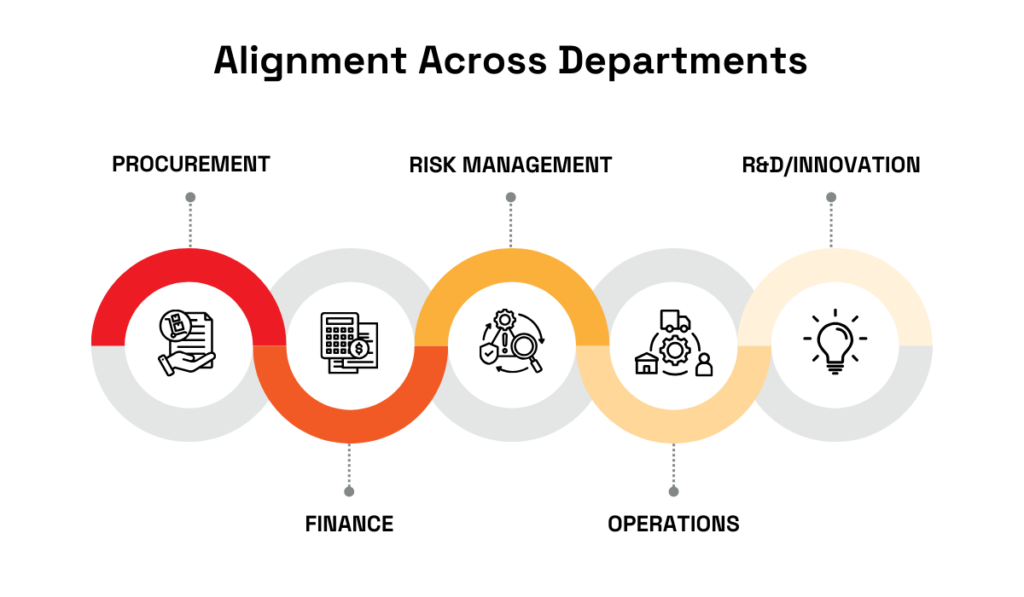

Another important factor here is that procurement teams need to stay aligned with several departments to make the most of SLM.

Source: Veridion

If you’re wondering what’s the one thing you can do to implement SLM practices, it’s to be aware that there are no shortcuts.

Eroding stakeholder resistance will take time, but with proper training, clear communication, and concrete results, the new supplier lifecycle management system will eventually fall into place.

SLM processes help strengthen supplier relationships, but collaborating with suppliers can be tricky at times.

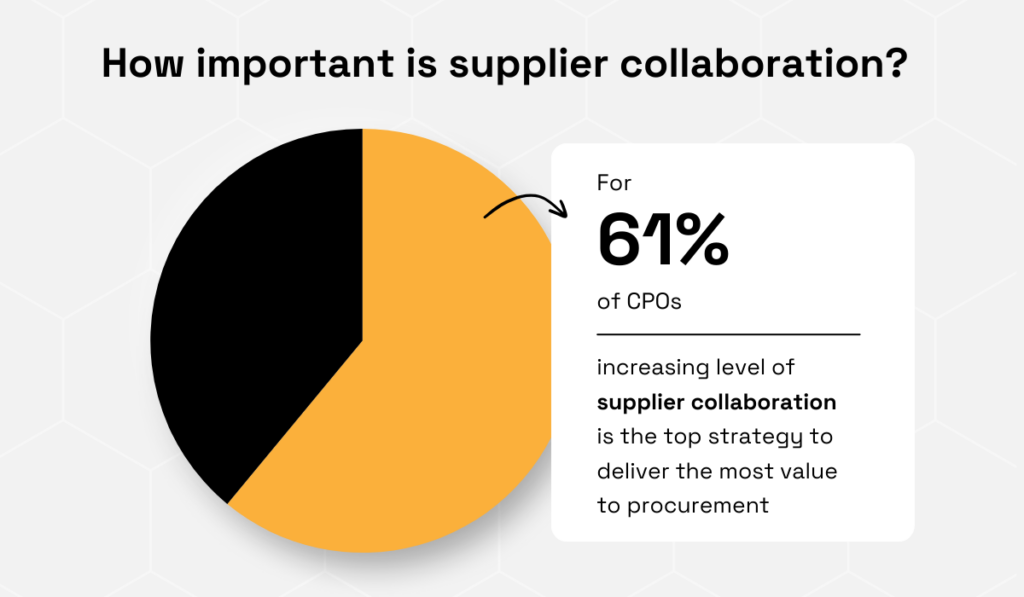

Deloitte’s 2023 Global CPO survey revealed that 61% of CPOs see great value in increasing supplier collaboration, but getting there requires significant effort.

Illustration: Veridion / Data: Deloitte

This is especially true when priorities or communication styles differ.

Even smaller misalignments on goals, expectations, or performance metrics can create friction, complicating lifecycle management and ultimately reducing the effectiveness of the partnership.

To give you an example, let’s say you’re expecting a key delivery within 30 days.

The supplier, however, interpreted the timeline as 30 business days instead of 30 calendar days, leading to delays.

As a result, you will perceive the supplier as unreliable, while the supplier might feel unfairly blamed for what they see as a miscommunication.

Small missteps like these can erode trust and impact critical processes such as performance evaluations and future negotiations.

So, what’s the only surefire strategy in such cases?

Danielle Salyers, the VP of Strategic Sourcing at Allied Solutions LLC, believes that promoting accountability for all is the best course of action.

Illustration: Veridion / Quote: Graphite Connect

Showing that you hold both sides to the same standards will help you find common ground and inspire mutual trust.

Ultimately, fostering a more collaborative approach through SLM takes up significant time and effort, but is one of the surest ways of building strong long-term partnerships.

As we’ve already established, access to quality supplier data is a key ingredient for successful supplier lifecycle management.

But how can you ensure the data you’re using is accurate and reliable?

One solution is to leverage cutting-edge services like those offered by Veridion, a leading provider of AI-powered business data.

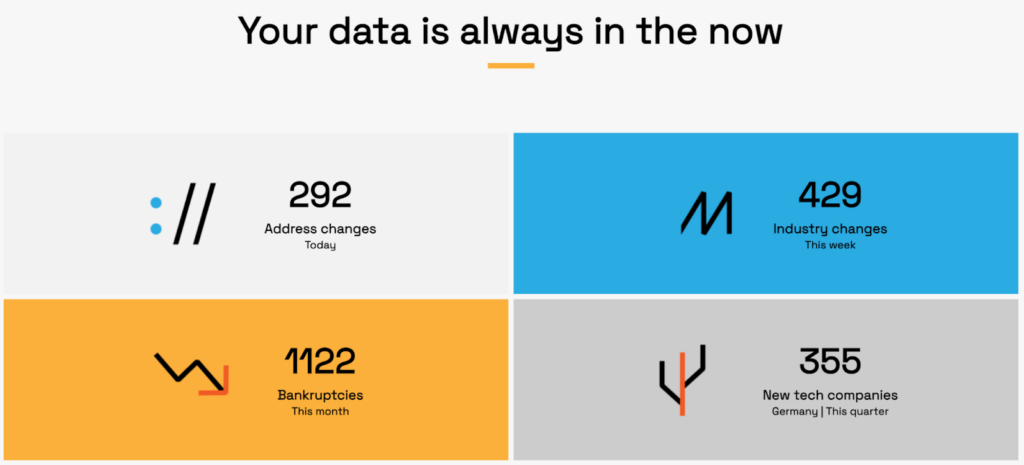

Veridion empowers organizations by offering weekly updated supplier intelligence.

Source: Veridion

With access to global supplier networks, organizations can make smarter decisions across all stages of SLM, from accelerating supplier discovery to gaining deeper performance insights.

Veridion also provides crucial risk management insights.

By capturing real-time data on supplier stability, compliance, ESG factors, and more, businesses can identify potential supplier risks and mitigate any disruptions before they escalate.

Source: Veridion

With Veridion’s global coverage and decision-grade data, organizations are equipped to enhance supplier relationships and ensure seamless SLM operations.

In a nutshell, accurate supplier data is the backbone of effective SLM.

Fortunately, new technologies give you access to that data, enabling more strategic decisions and stronger supplier partnerships.

Supplier lifecycle management fuels procurement success.

By optimizing each stage of SLM, you’ll reap numerous benefits, from stronger partnerships and cost efficiency to proactive risk mitigation.

You’ll inevitably face challenges along the way, but they’re easier to overcome with the right mindset and reliable data.

Remember: incorporating SLM practices into your strategy is just the first step.

Stay proactive and adaptable, keep innovating, and you’ll turn obstacles into opportunities in no time.