9 Types of Supplier Sourcing You Need to Know About

Supplier sourcing is one of the key functions of procurement.

It’s all about securing the best products from the most reliable suppliers at the best prices—while also ensuring timely deliveries to keep the operations running smoothly.

But did you know there’s more than one way to do this?

In this article, we explore nine supplier sourcing strategies you need to be aware of.

We’ll go over each type’s advantages and challenges, and share real-world examples and statistics to give you a fuller picture of how these strategies work.

So, get ready to discover some new sourcing techniques that could elevate your own sourcing strategy to the next level.

Some companies prefer to have complete control over production so they handle everything internally, while others choose to delegate all responsibilities to external parties.

This results in two distinct approaches to supplier sourcing based on resource allocation: insourcing and outsourcing.

Let’s break them down.

Insourcing is when companies use their own resources, employees, and infrastructure to perform tasks and produce goods that would otherwise be outsourced to third-party providers.

Instead of relying on external suppliers, the company manages its supply chain needs internally.

Business leaders love this approach because it offers greater control over processes, which can result in higher product quality.

This is exactly why CERN recently began insourcing the production of its beryllium beam pipes.

Source: CERN Courier

After their last supplier discontinued production, CERN decided to build its own manufacturing facility to make the pipes in-house.

As per CERN Courier, this move gives CERN “direct control of the manufacturing process, allowing stricter quality assurance and greater flexibility to meet changing experimental requirements.”

However, the major downside to insourcing is the high upfront cost.

Insourcing often requires significant investment in infrastructure and training.

Take Rockford City Council, for example.

They’re planning to spend $1.8 million to bring their IT services in-house.

According to their IT Director Todd Hughes, it’s a long-term investment that will eventually pay off.

Illustration: Veridion / Quote: Rockford Register Star

But not every organization has that kind of money lying around.

For those with tighter budgets, these initial costs can be a considerable roadblock, despite the potential for an improved product or process quality.

Outsourcing is the opposite of insourcing.

It involves transferring products or services that were once handled internally to third-party vendors.

This strategy is often used to reduce costs and simplify internal operations.

New Zealand’s Ministry of Business, Innovation and Employment knows this very well.

After spending NZ$2.45 million and about 8 years on the in-house development of a national research information system, they finally decided to scrap it and outsource it to a commercial provider.

Source: Research Professional News

Danette Olsen, General Manager at the ministry, said that “testing found that a prototype system for NZRIS was processing data incorrectly”.

She elaborated:

“A technical review was commissioned to identify the cause of these issues and propose solutions. The review found that the system’s architecture was overly complex and would likely require significant re-engineering.”

Ultimately, they concluded that commercial software offered “better value for money” compared to developing their own.

While outsourcing can be cost-effective, it can also cause dissatisfaction among workers, especially if it results in job losses or pay cuts.

For instance, just recently, cleaners at the Royal Hobart Hospital went on strike after the hospital decided to outsource its cleaning services.

Source: Pulse Tasmania

Outsourcing might be a popular choice for businesses, but transitioning from insourcing can take a toll on employee morale, and in some cases, it can even tarnish an organization’s reputation.

Now, let’s take a look at sourcing types based on the location of chosen suppliers.

Near-sourcing is a strategy focused on procuring goods and services from suppliers located closer to the end customer or the buyer.

This reduces lead times and shipping expenses, providing companies with greater agility in managing their supply chains.

The UK retailer Marks & Spencer experienced this flexibility firsthand.

After suffering a 75% drop in clothing sales during the pandemic, the company adopted the near-sourcing strategy.

Their CEO at the time, Steve Rowe, explained that, after the pandemic, they simply had to evolve their procurement practices to keep up with changing customer habits.

Illustration: Veridion / Quote: Just Style

This approach allowed them to, instead of overstocking and hoping for sales, order exactly what they need, when they need it, thanks to faster turnaround times.

Still, this method comes with its trade-offs.

While it saves time and money, it limits the pool of suppliers, which can reduce innovation and cause over-reliance on certain vendors.

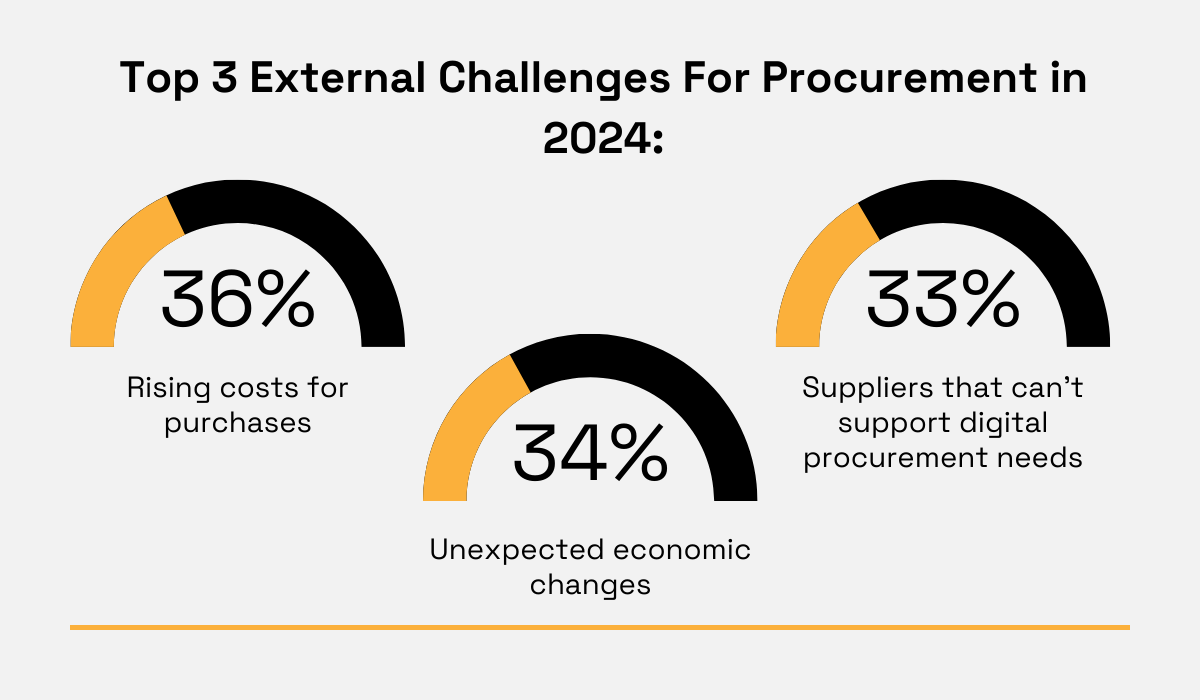

The following data shows why that can be quite a hurdle for modern sourcing teams.

According to an Amazon Business survey, the top challenges procurement currently faces are rising costs and unexpected economic changes.

Illustration: Veridion / Data: Amazon Business

In such a landscape, fewer supplier options can make it tough to address these risks, potentially affecting overall profitability and slowing down production.

Low-cost country sourcing (LCCS) focuses on procuring products and services from countries where production and labor costs are significantly lower than in the buyer’s home country.

The main benefit is obvious: cost savings.

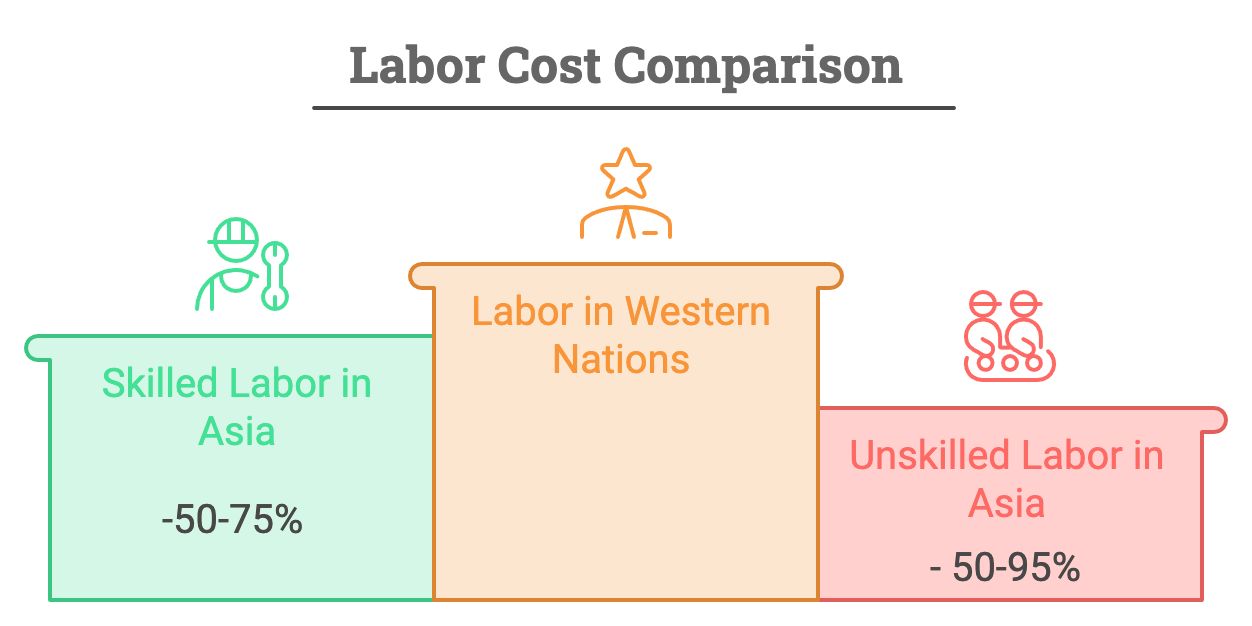

According to GEP, skilled labor in low-cost Asian countries can cost 50-75% less than in Western nations, while unskilled labor can be as much as 95% cheaper.

Illustration: Veridion / Data: GEP

However, this sourcing type isn’t without its downsides.

It can result in longer lead times, less control over production quality, and supply continuity issues.

Perhaps this is why LCCS is losing some of its appeal.

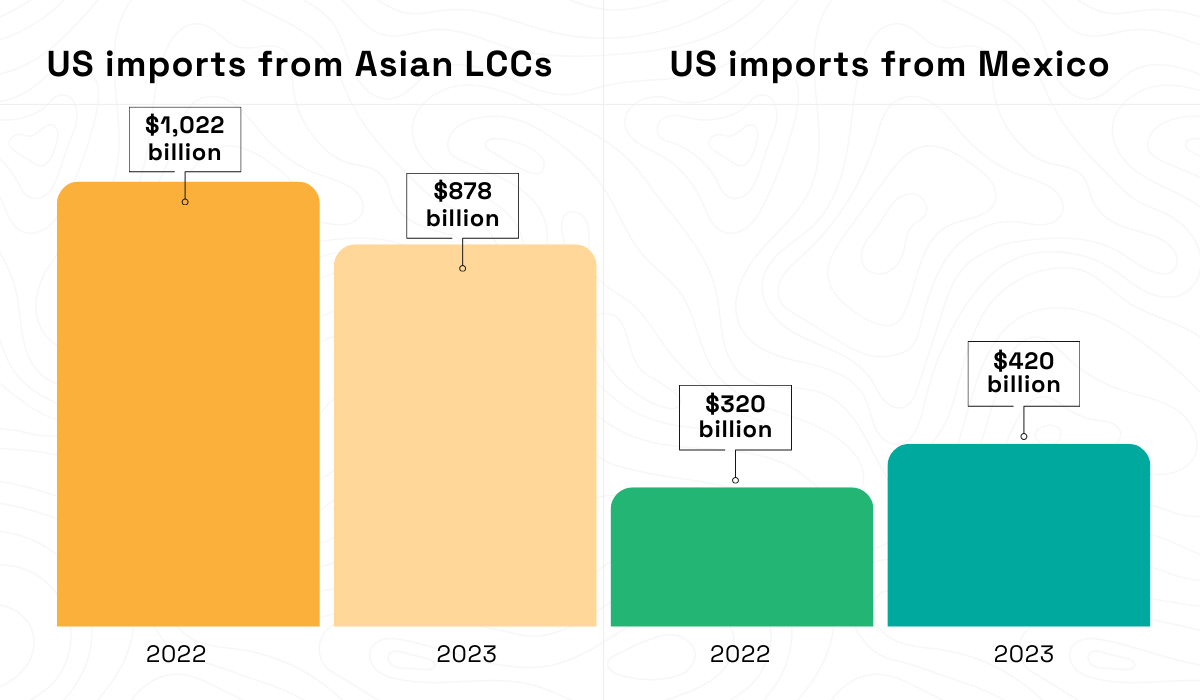

The Kearney 2024 Reshoring Index report shows that U.S. imports from 14 low-cost Asian countries declined from $1 trillion in 2022 to $878 billion in 2023—a significant drop within just one year.

At the same time, we see the U.S. starting to rely on suppliers closer to home.

Namely, imports from Mexico increased from $320 billion to $422 billion, with Mexico surpassing China as the U.S.’s largest supplier for the first time in the report’s 11-year history.

Illustration: Veridion / Data: Kearney

Still, LCCS probably isn’t going away anytime soon.

As long as cost savings remain a top priority for procurement teams, this strategy will continue to be a go-to option for businesses looking to trim expenses.

Global sourcing taps into suppliers from around the world, offering companies access to a broader range of vendors, lower prices, innovative products, and more.

The primary advantage of this approach is the opportunity for diversification, which enables companies to build a flexible, multi-supplier base that can help mitigate various risks.

Eclat Textile Co., a supplier of sportswear for Nike and Lululemon is a prime example of why relying on only one supplier/supplier location is never a good idea.

In 2016, Eclat shifted imports away from China to Vietnam, due to unfavorable manufacturing conditions.

But by 2019, with the escalating global trade war, Vietnam no longer seemed as secure, prompting Eclat to broaden its supplier base once again.

Their chairman of the board, Hung Cheng-Hai highlighted the importance of diversification and its role in ensuring resiliency.

Illustration: Veridion / Quote: Al Jazeera

Now, global sourcing is sometimes criticized as a challenging, overly complex process.

Just trying to find reliable information on suppliers across different countries—each with its own cultures, regulations, and logistical challenges—can be quite time-consuming and frustrating.

And this can, in turn, result in many costly mistakes.

Luckily, there are new, advanced tools that are taking the guesswork out of global sourcing.

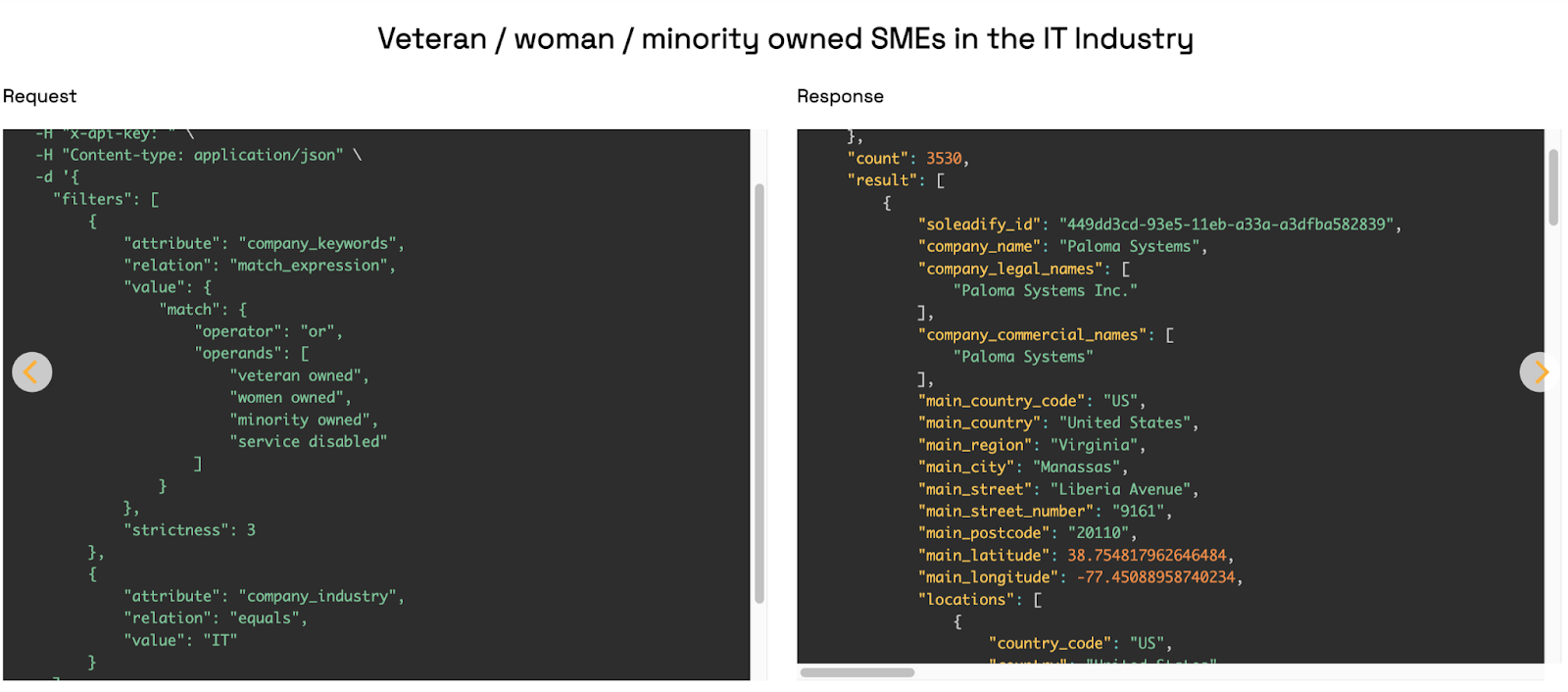

Veridion, for instance, is an AI-powered platform that gives companies instant access to millions of vetted suppliers worldwide.

Looking for a solar panel manufacturer in Southeast Asia that meets your specific sustainability standards?

Or, perhaps you’re interested in European, women-owned SMEs in the IT Industry?

With Veridion, you can find the perfect match in minutes, no matter the criteria.

Source: Veridion

The best part?

Veridion’s database is updated weekly, ensuring the information is always fresh.

It’s like having the entire global supply chain at your fingertips.

You just need to pick the supplier that best fits your needs.

Supplier sourcing can also be categorized based on the number of suppliers involved.

Let’s explore some of them.

Sole sourcing occurs when only one supplier can fulfill a buyer’s requirements, often due to proprietary technology, patents, or a unique offering.

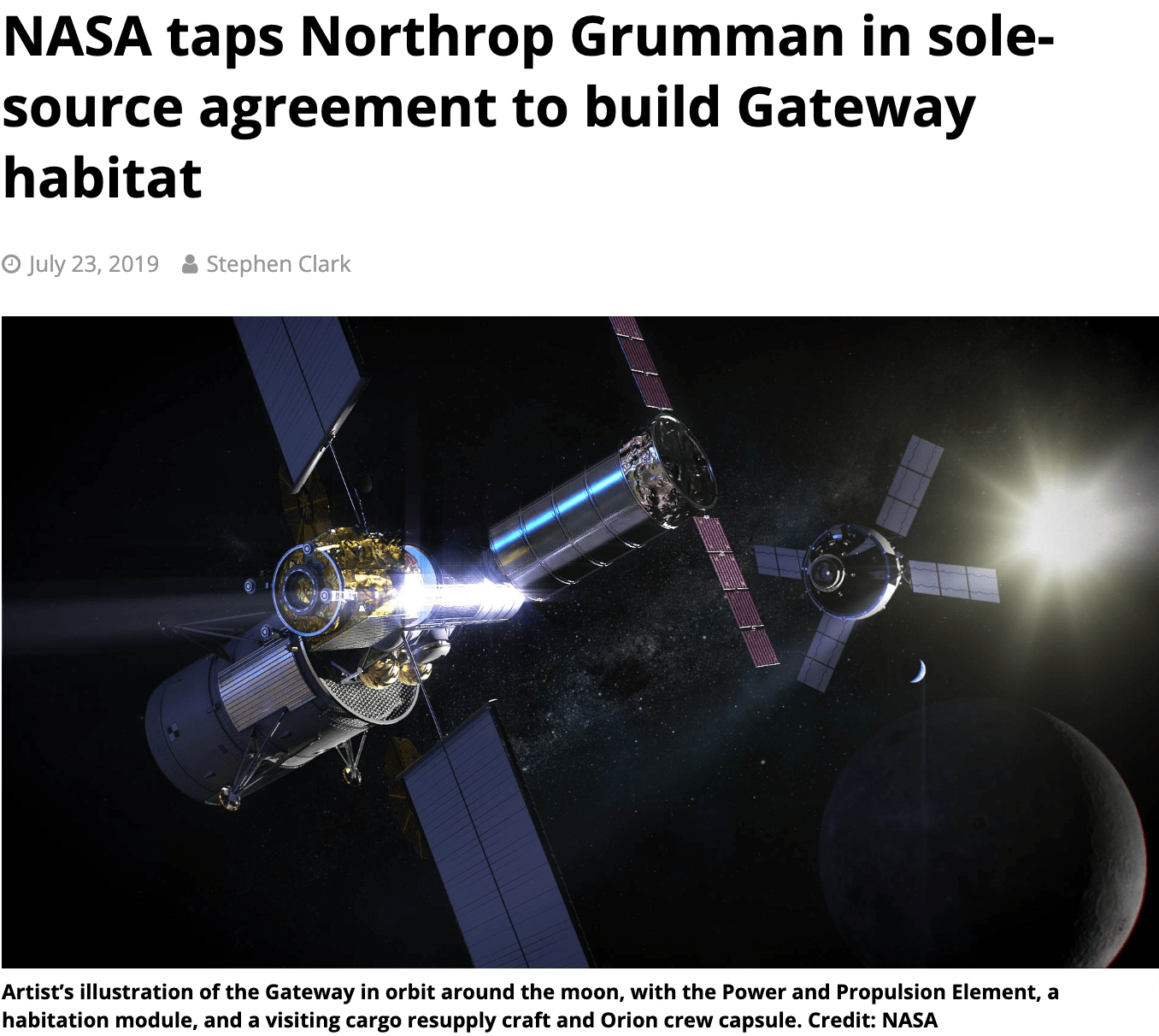

In 2019, for example, NASA awarded a sole-source contract to Northrop Grumman for a pressurized habitation module because no other company could meet their tight schedule.

Source: Spaceflight Now

According to SpaceNews, NASA “did allow other companies to submit information about their capabilities by June 13, but none did so.”

On one hand, sole sourcing ensures access to specialized goods or services that no one else can provide. On the other, it creates a heavy dependency on the supplier, which can lead to all sorts of issues.

Ontario’s Landlord Tenant Board learned this the hard way.

More than three years ago, they gave a sole-source contract to an international accounting firm to build a digital tribunal system for them.

Initially estimated at less than $1 million, the project ballooned to over $26 million through change orders and contract add-ons.

When questioned why the contract wasn’t put out to tender, Attorney General Doug Downey defended the decision, claiming no other firm could deliver:

“Lots of choices to be made, we went with those who had the experience and had a product that was actually operating and operating very well.”

However, Toronto CityNews’ sources allege that the organization is, in fact, quite dissatisfied with the project, due to constant delays and cost overruns.

But now, they are stuck in the deal.

This is a classic example of the risks that come with sole sourcing: when you’re locked in, there’s no easy way out, even when things go wrong.

With single sourcing, a company has other options but deliberately chooses to work with a single supplier.

That can lead to improved supplier relationships and preferential treatment.

Some research even indicates that this approach can improve operational efficiency and yield better business outcomes.

For example, in the study titled Strategic Sourcing of Multi-Component Software Systems: The Case of Electronic Medical Records, the authors suggest that patient care improves when hospitals select a single vendor for their medical records software.

Ken Kelley, one of the co-authors, elaborates:

“To put this into perspective, during the timeframe of our study, U.S. hospitals admitted approximately 35 million patients per year. All else being equal, if hospitals moved slightly closer to single-sourcing in a given year, say 0.5 units, approximately 175,000 more patients per year would have received evidence-based care.”

This is because using multiple EMR vendors can create mismatches between supplier components, resulting in inconsistent and disrupted data exchange.

For instance, allergies might be defined and coded differently across EMR components from different suppliers.

And, naturally, such inconsistencies negatively affect the quality of patient care.

Just like any other strategy that doesn’t prioritize diversification, single sourcing carries risks related to supplier over-dependency.

Camille Batiste, Former SVP of Global Supply Chain & Procurement at ADM, a global human and animal nutrition company, cautions that putting all your eggs in one basket is never a wise choice.

Illustration: Veridion / Quote: Supply Chain Dive

If a vendor encounters issues, whether it’s financial instability, operational disruptions, or strikes, the buyer’s supply chain is at significant risk as well.

In dual sourcing, the procurement of goods and services is divided between two suppliers, where one serves as a backup if the other fails to deliver.

This approach can be very effective in preventing supply and production disruptions.

That’s why Qualcomm’s CEO is reportedly considering collaboration with Samsung to diversify the sources for the Snapdragon 8 Gen 5 smartphone chip.

Source: TrendForce

By partnering up with Samsung alongside TSMC, Qualcomm is positioning itself to meet rising demand for its product head-on, while simultaneously reducing the risk of bottlenecks in production.

Although dual sourcing is a smart way to mitigate risk while maintaining a manageable supplier base, this strategy isn’t without its issues.

One major challenge is the potential for inconsistencies in product quality.

Since each supplier may have different manufacturing processes, slight variations can creep in, impacting the quality of the final product.

Remember, customers are quick to notice any discrepancies in quality.

And if they don’t like what they see, the trust they place in the brand can be jeopardized.

Multi-sourcing involves procuring the same product or service from multiple suppliers.

This strategy increases competition among vendors, which opens doors to more cost-reduction opportunities, minimizes the risk of disruptions, and improves a company’s overall agility.

Take the Italian food company, Barilla, for example. They were able to successfully navigate inflation by leveraging this strategy.

Luigi Ganazzoli, their Vice President of Purchasing provides more details.

Illustration: Veridion / Quote: Procurement Leaders

However, multi-sourcing also introduces greater complexity in supplier management.

As a company’s supplier base expands, it becomes increasingly difficult to devote the necessary attention to each supplier and cultivate the quality partnerships that are essential for long-term success.

A successful sourcing strategy is somewhat of a balancing act.

A diverse supplier base prevents disruptions in the supply chain.

On the other hand, too many suppliers can make it hard for you to efficiently manage their performance and build strong relationships.

Similarly, relying solely on suppliers in distant countries can hinder effective communication and limit control over production, but working exclusively with local suppliers limits your opportunities for cost-savings and innovation.

In short, a perfect sourcing strategy doesn’t exist.

You can come close to it, however, by mixing and matching elements from all the strategies we’ve explored.

The good news is that thanks to modern supplier sourcing tools, discovering suppliers that perfectly fit your unique needs has never been easier and more efficient.