7 Trends That Are Transforming Supply Chains

Ever feel overwhelmed by the rapid changes in supply chain management?

As tough as it is, the reality is that procurement professionals must keep up with these changes.

After all, staying ahead of the curve is crucial, especially when emerging trends can potentially reshape your operations entirely.

That’s why, in this article, we’re exploring seven of the biggest trends reshaping the future of supply chains.

So, if you want to discover what’s coming and how you can prepare for it, read on.

Artificial Intelligence is the talk of the tech world, transforming industries across the board, and supply chains are no exception.

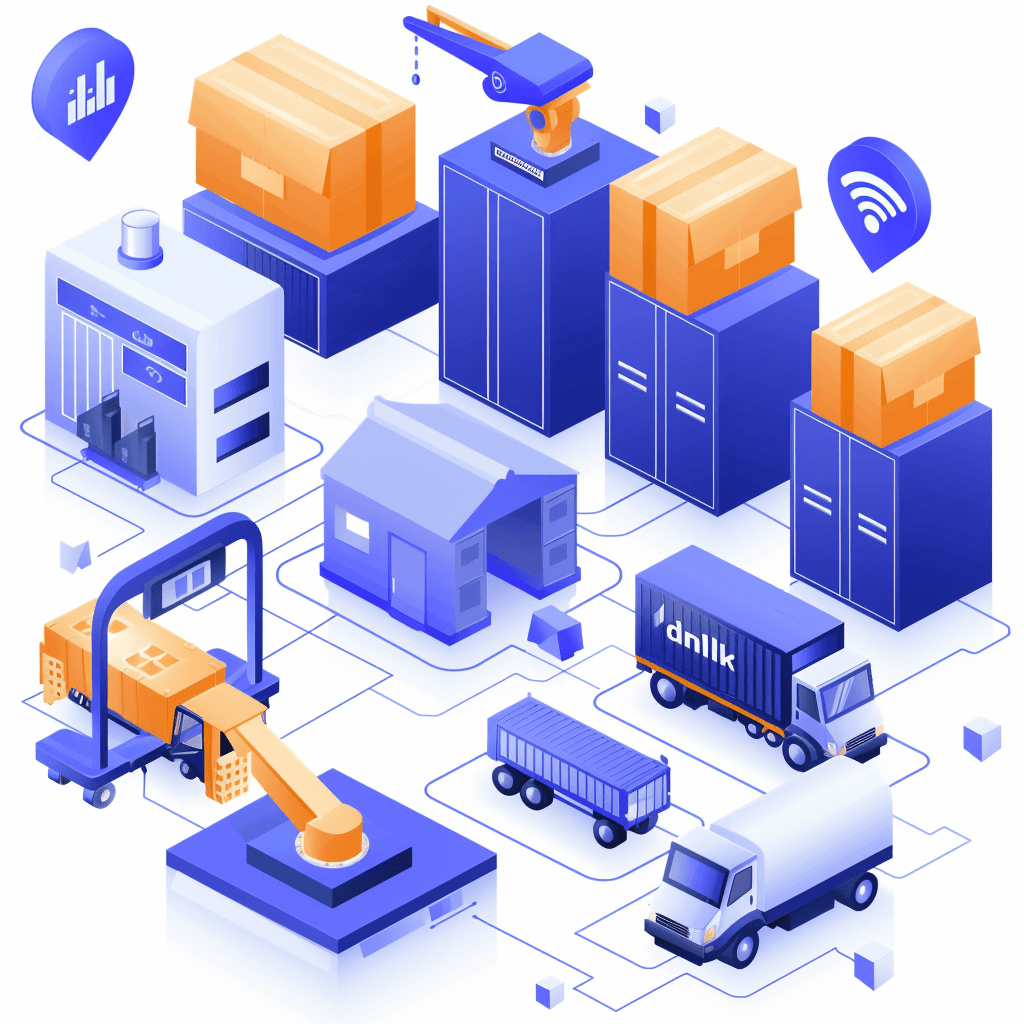

A 2024 report by Meticulous Research predicts that AI in the supply chain market will explode in the coming years, reaching a staggering $58.55 billion by 2031.

Illustration: Veridion / Data: Meticulous Research

This massive growth is fueled by the increasing adoption of AI technologies like machine learning, natural language processing, computer vision, and predictive analytics.

Among these technologies, we’re seeing the wide adoption of generative AI (GenAI).

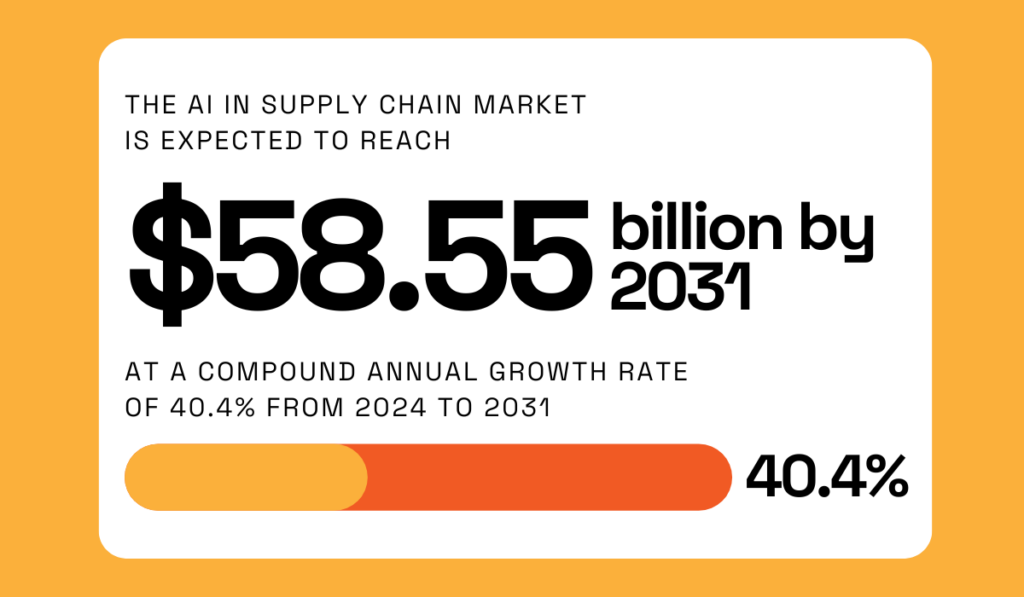

A recent Gartner survey found that half of supply chain organizations plan to put this technology into action in 2024, with 14% already in the implementation phase.

Source: Gartner

In the supply chain context, organizations are turning to GenAI to analyze their vast amounts of data and identify patterns, generate insights, and even predict future trends.

It can also automate tasks, such as report generation, demand forecasts, and even logistics planning.

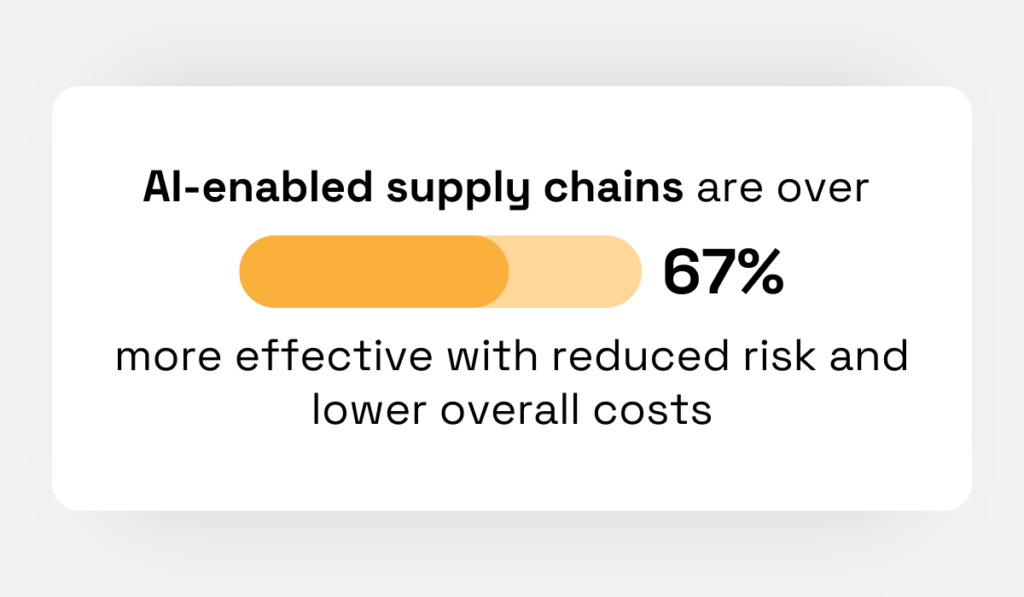

Data is already emerging that shows the benefits of AI in supply chains.

For example, Research and Markets data reveals that AI-enabled supply chains are more effective overall.

Illustration: Veridion / Data: Research and Markets

With procurement experts at the steering wheel, GenAI will increasingly make manual and data-crunching processes more efficient and cost-effective.

Also, by analyzing vast datasets in ways that no single human can, it can help get insights and reduce risks across the supply chain.

This is just the beginning of the AI revolution, and the potential for further innovation and improvement is immense.

With AI and tech-driven supply chains on the rise, the skills needed for success in procurement and supply chain management are evolving, too.

We’re talking about developing the digital skills necessary to leverage these new technologies, analyze data, and make informed decisions.

Alex Saric, CMO at Ivalua, a global leader in spend management solutions, shared his insights on the present and future of technology in procurement.

Illustration: Veridion / Quote: SupplyChainDigital

Saric emphasizes that technology is and will continue to be the key driver of value creation in procurement.

But, he also points out a potential challenge: the worry that procurement teams may struggle to develop the necessary digital skills, or that organizations will face difficulties hiring the right experts.

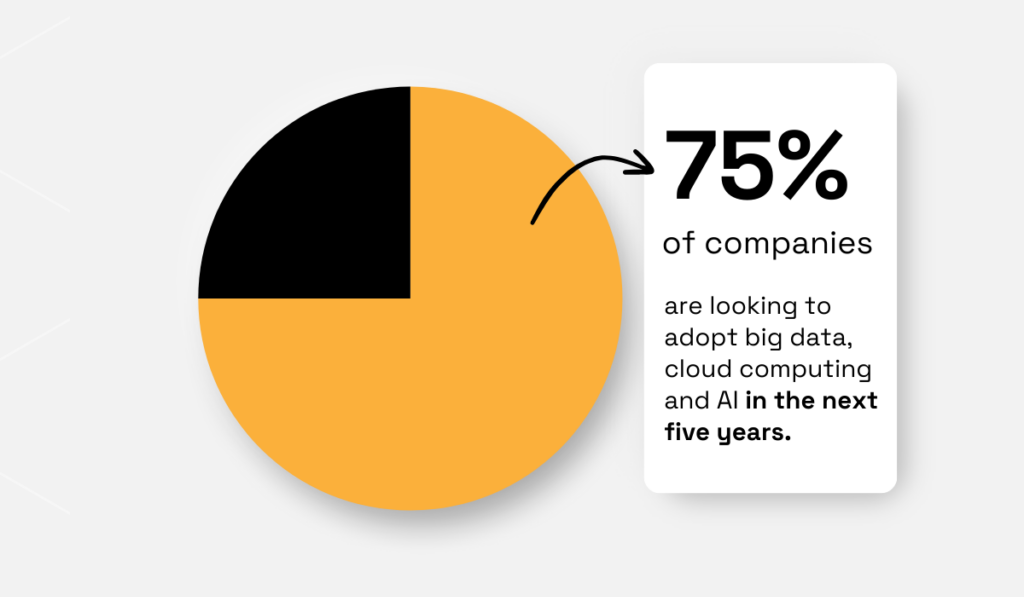

This concern is even greater when you consider the fact that the vast majority of companies are investing in and adopting big data, cloud computing, and AI in the next five years.

Illustration: Veridion / Data: WEF

This points to the fact that procurement professionals must adapt and evolve, or risk being left behind in an increasingly digital landscape.

With a wealth of formal and informal training opportunities and courses available to teach these emerging technologies, it’s imperative that both individuals and organizations take proactive steps to upskill and reskill their workforce.

Source: Coursera

Procurement executives can invest in their team’s education by sponsoring training programs, workshops, and online courses.

On top of that, they can seek out professionals who have already developed the necessary digital skills and bring them into their teams.

Ultimately, those who embrace digital transformation and invest in developing the skills of the future will be best positioned to thrive.

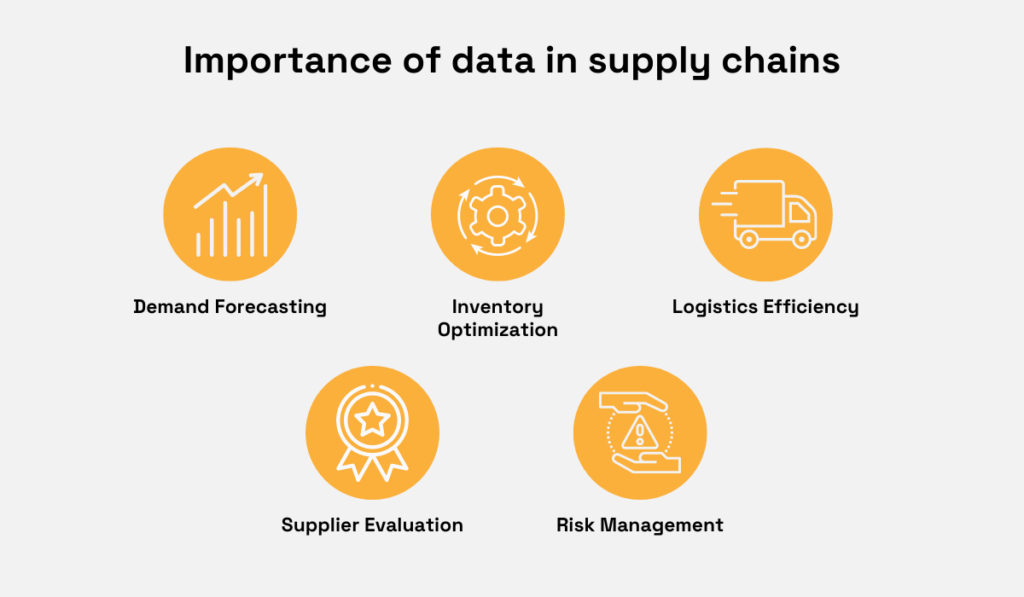

We touched on the importance of data in the previous section, so let’s elaborate on this topic a bit more.

In supply chains, there’s a vast array of information collected at various points throughout the supply network.

This includes everything from inventory levels and shipping times to supplier performance and customer demand patterns.

While data has always been important, its significance is growing exponentially with the rise of big data and advanced technologies that can collect, analyze, and interpret it more effectively than ever before.

Source: Veridion

Digital technologies like AI and machine learning (ML) are revolutionizing how companies leverage data in supply chains.

These tools can analyze large amounts of data to identify patterns, trends, and anomalies, providing insights that can help improve demand forecasting, inventory optimization, and logistics planning.

But it’s not just about analyzing existing data—there’s also a shift towards collecting even more data to track and manage supply chains.

For example, we’re seeing Radio Frequency Identification (RFID) and the Internet of Things (IoT) being integrated into supply chain management.

Source: Science Direct

RFID tags and IoT sensors can be attached to products, pallets, or even shipping containers, providing real-time data on their location, condition, and movement.

This data can be used to track inventory levels, monitor shipments, and identify potential bottlenecks or delays in the supply chain.

Or consider supplier selection and evaluation.

Accurate and up-to-date data from platforms like Veridion can be used to assess supplier performance, identify risks, and compare different suppliers based on key criteria such as quality, delivery time, and price.

Source: Veridion

In recent years, we’ve unlocked the ability to not only process our existing data but also collect and analyze even more of it.

Procurement professionals should seize the opportunities this presents to gain valuable insights and drive continuous improvement in their supply chains.

In this data-driven era, the ability to harness the power of information is essential for success.

Now let’s turn to visibility in the supply chain.

This refers to the ability to track and monitor every aspect of the supply chain process, from raw material sourcing and production to transportation, warehousing, and delivery.

It involves having real-time access to data and insights on inventory levels, order status, shipment locations, and potential disruptions.

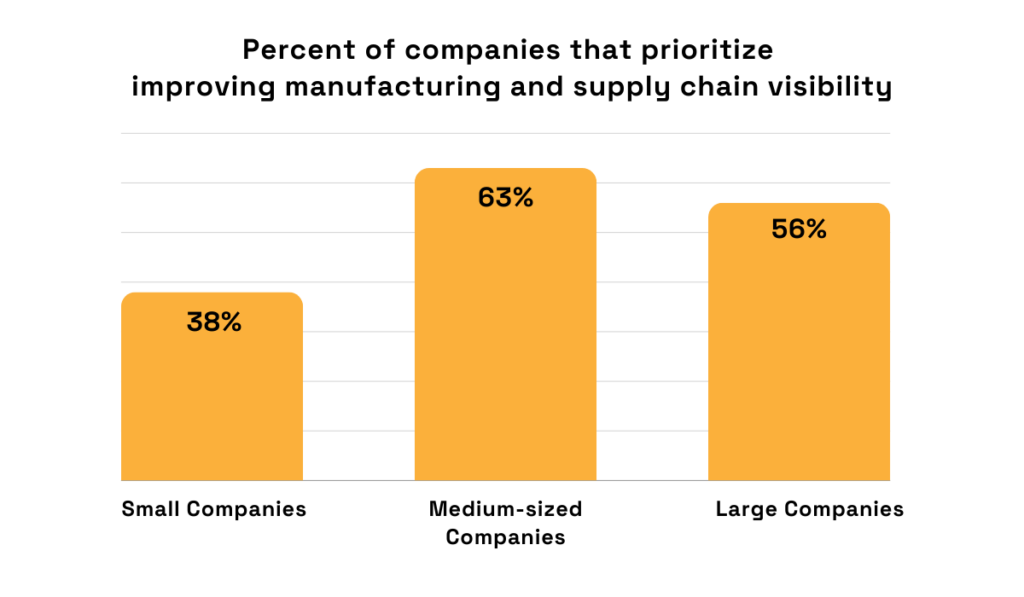

More and more companies are prioritizing the improvement of supply chain visibility.

This trend is highlighted in the 2023 State of Manufacturing Report by Fictiv, which surveyed over 240 leaders in engineering, supply chain, manufacturing, and product development.

The report revealed some interesting insights about the prioritization of visibility in different-sized companies, shown below.

Illustration: Veridion / Data: Fictiv

For over half of medium-sized and large companies, manufacturing and supply chain visibility are top priorities.

This is because greater visibility enables better decision-making, risk mitigation, and cost optimization.

For smaller companies, it’s not as high a priority, possibly due to limited resources or less complex supply chains.

However, as these companies grow, they’ll likely face increasing pressure to improve visibility in order to remain competitive.

But while visibility is a priority, according to supply chain expert Lora Cecere, leaders are not making significant progress.

Illustration: Veridion / Quote: Forbes

She cites industry data showing a widening gap between the importance of visibility in manufacturing, suppliers, logistics, and enterprise, and the actual progress and effectiveness of visibility efforts.

While organizations are turning to digitalization to bridge this gap, there are also organizational barriers.

These include poor information flow and communication across departments, as well as difficulties in truly understanding and integrating new technologies.

In the end, this tells us that achieving true visibility requires not just technological investment, but also a commitment to cultural change and cross-functional collaboration within the organization.

Beyond visibility, another crucial focus area for supply chains is efficiency, specifically when it comes to introducing new products.

New product introduction (NPI) is the entire process of bringing a new product to market, from initial concept to launch.

It’s a complex process that involves multiple stakeholders and can often be fraught with challenges and delays.

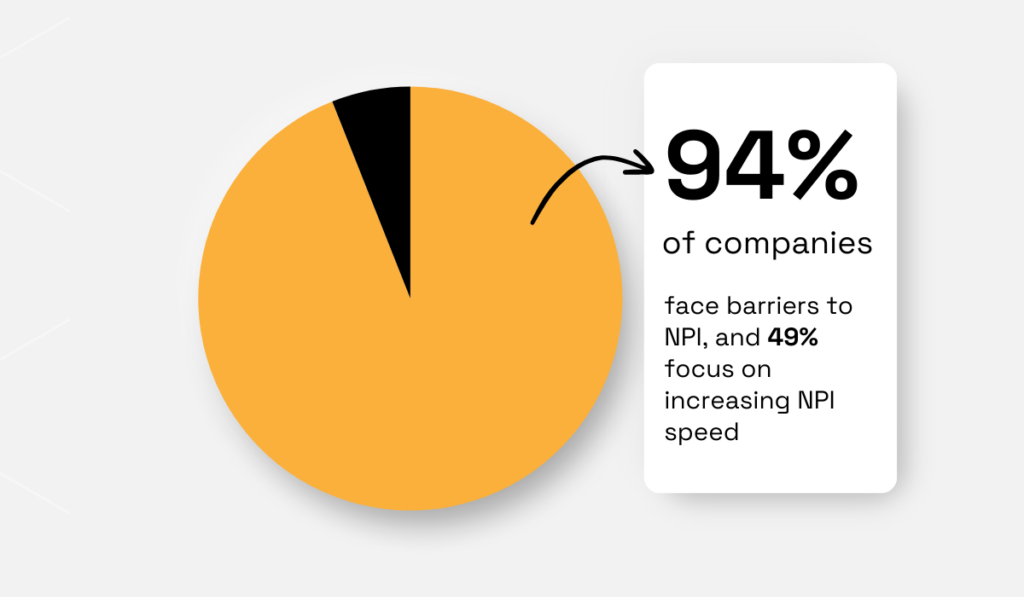

According to Fictiv’s report we mentioned earlier, nearly half of organizations are prioritizing increasing their NPI speed.

Unfortunately, the same report reveals that an even larger percentage, 94%, face barriers to NPI.

Illustration: Veridion / Data: Fictiv

These barriers can include:

Despite these challenges, the push for NPI speed is accelerating, especially considering the significant benefits it can offer.

Source: Veridion

Introducing products to market faster than competitors provides a tremendous competitive advantage.

It allows companies to capture market share early, establish brand dominance, and generate revenue sooner.

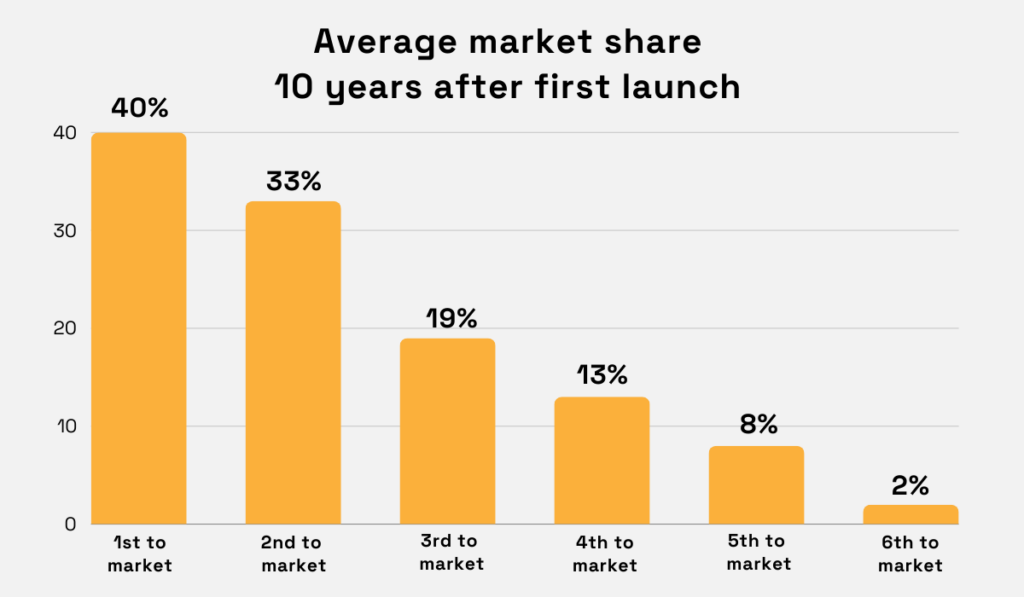

This is supported by LNS research data, which examined pharmaceutical companies releasing similar new products.

The companies that were first to market maintained a significantly larger market share even ten years after launch.

Illustration: Veridion / Data: LNS

This advantage stems from factors like brand recognition, customer loyalty, and the ability to establish a strong market presence early on.

Moreover, early market entrants often benefit from premium pricing, as they can have higher prices before competitors enter the market and drive prices down.

Considering these benefits and the ever-changing nature of consumer preferences, speeding up NPI can enable companies to be more agile, responsive, and adaptable to market demands.

A crucial aspect of supply chain effectiveness is how inventory is handled.

We’re seeing a move towards more strategic, data-driven inventory management practices.

These practices are a much-needed correction to some of the inefficiencies we’ve seen in the recent past, especially with the pandemic-induced supply chain disruptions.

A few years ago, the supply chain chaos caused by the pandemic led organizations to adopt extreme inventory management practices.

As Radu Palamariu, Managing Director at Alcott Global, a leading management consulting firm, explained for Forbes, this was risky.

Illustration: Veridion / Quote: Forbes

But over and understocking is not a problem of the past.

Supply chains are still facing challenges, and evolving consumer demands require more flexible and responsive inventory management.

To address these challenges, new inventory management practices are being developed and adopted, such as:

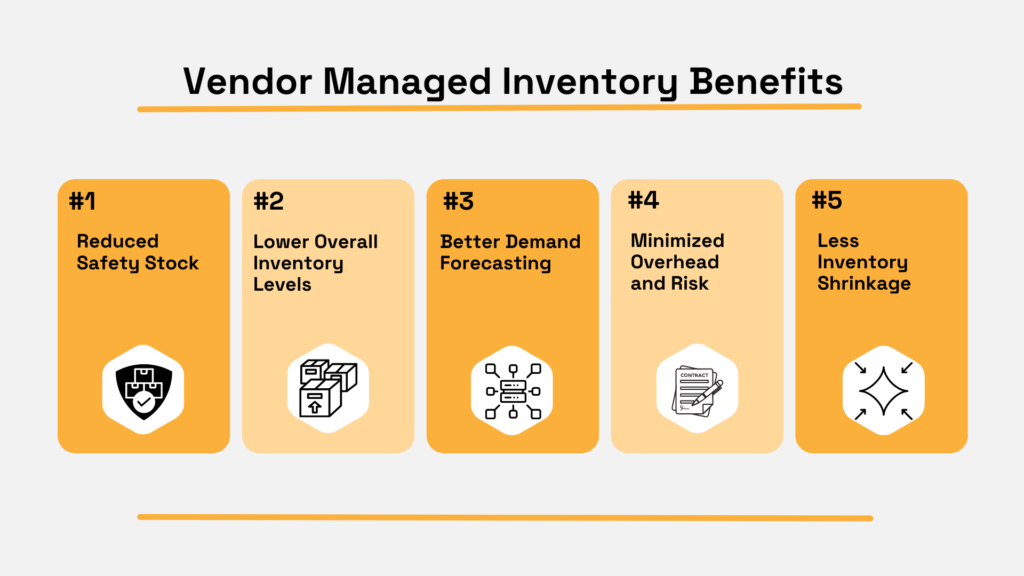

One practice that directly addresses the issue of balancing overstocking and stockouts is Vendor-Managed Inventory (VMI).

In this model, the supplier takes responsibility for managing the retailer’s inventory levels and replenishing stock as needed.

Source: Veridion

VMI and other emerging technologies allow organizations to be agile, working with less stock and lower overhead costs while still meeting customer demand.

Tech like AI can analyze demand patterns and introduce optimization, while things like blockchain technology promise to enhance transparency and traceability throughout the supply chain.

All in all, these data-driven approaches and innovative technologies are the much-needed future of inventory management.

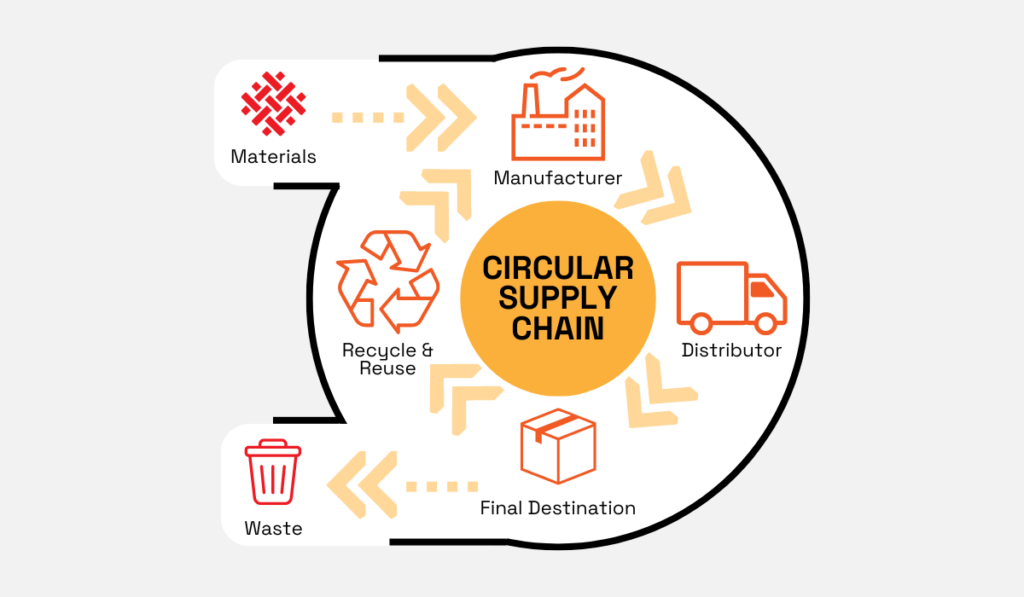

The final trend we’ll explore is the general industry shift towards sustainability, with a particular focus on circular supply chains.

Unlike traditional linear supply chains, which follow a “take-make-dispose” model, circular supply chains create a closed loop where resources are continuously reused and recycled.

Source: Veridion

This approach involves designing products for durability and repairability, extending their lifespan through reuse and refurbishment, and ultimately recovering valuable materials for recycling at the end of their life.

The benefits of circular supply chains are far-reaching, covering environmental, social, and economic advantages.

| CATEGORY | BENEFITS |

|---|---|

| Environmental | Reduced waste, lower carbon emissions, conservation of natural resources, decreased pollution, promotion of biodiversity |

| Social | Job creation, improved working conditions, community engagement, ethical sourcing |

| Economic | Cost savings, innovation opportunities, increased resource efficiency, enhanced brand reputation |

Driven by sustainability initiatives and increasing regulations, many organizations are adopting circular supply chain practices.

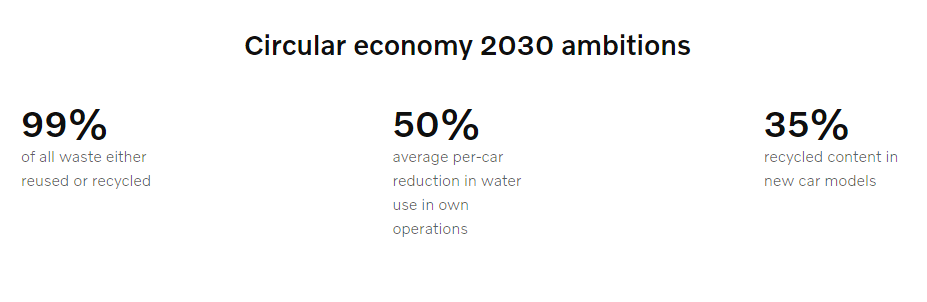

For instance, Volvo has publicly displayed their ambitious 2030 circular economy goals.

Source: Volvo Cars

By reducing waste throughout the production process and incorporating more recycled content into new vehicles, trailblazers like Volvo aim to minimize their environmental footprint, conserve valuable resources, and enhance their brand image as a sustainable and responsible company.

Given the numerous benefits and growing momentum of circular supply chains, we can expect to see more companies embracing this approach in the near future.

Hopefully, this article has given you a glimpse into what the future holds for procurement and supply chain management.

As you’ve seen, there’s a growing need for digital tools, accurate data, and using AI to streamline processes.

Also, by focusing on better visibility, sustainable practices, and efficient inventory management, organizations are striving to build more resilient and adaptable supply chains.

We hope this overview has not only informed you but also inspired you to explore these trends further.

By staying informed and embracing innovation, you can position your organization at the forefront of the evolving supply chain landscape.

The future is now—so let’s get ready to transform our supply chains for the better!