How to Manage Procurement Risk in 6 Steps

Procurement teams constantly face risks that can disrupt procurement operations, add unexpected costs, and even damage the organization’s reputation.

If you’re looking for a clear, step-by-step approach to managing these risks proactively, this article has you covered.

We’ll explore the six key steps you need to follow for a strong procurement risk management process.

This includes everything from the initial risk identification and assessment to the importance of putting some essential systems in place to keep an eye on future issues.

And most importantly, we’ll cover how to translate these concepts into practical activities that you can implement within your organization.

Let’s get started.

Before diving into risk mitigation strategies, the first crucial step is to identify the specific risks lurking within your procurement processes.

Identifying risks can be achieved through a combination of approaches, whether it’s brainstorming sessions with your procurement team or analyzing historical procurement data to reveal patterns or past incidents that highlight areas of vulnerability.

Most importantly, you need to start by examining each stage of your procurement process step-by-step as it’s the most methodical way to identify risks.

Let’s break down these procurement stages and show some common risks that can emerge.

Source: Veridion

Potential risks can arise from the very first step.

After all, without proper communication throughout your organization, you risk procuring the wrong items, quantities, or services altogether.

Supplier risks are another major concern—a poor selection process could lead to unreliable suppliers, while poorly negotiated contracts may open the door to costly legal disputes.

Additionally, supplier quality issues and delivery delays can significantly disrupt operations if left unchecked.

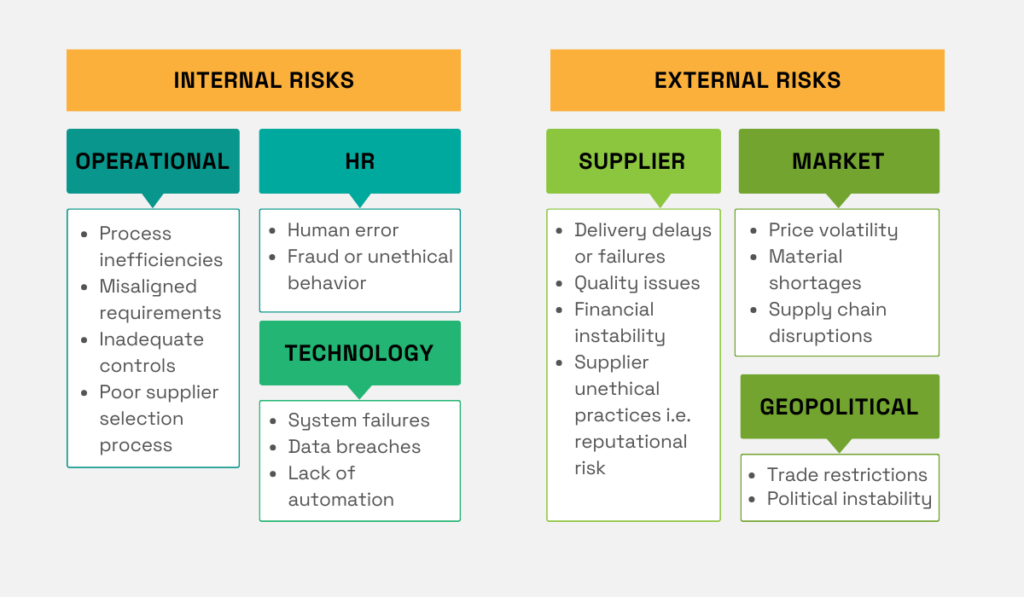

To ensure you don’t overlook any potential problems, try to examine both internal and external risks.

Source: Veridion

Internal risks stem from inefficiencies within your own organization.

You can spot operational risks where some procurement processes are outdated, while HR risks like human error or fraudulent activity might appear when there aren’t any safeguards and regular training for procurement staff.

External risks, especially ones related to suppliers, will require careful ongoing monitoring to quickly spot potential supplier issues.

On the other hand, market and geopolitical risks can pose unique challenges and are difficult to control fully, but identifying them early is crucial to developing contingency plans.

Overall, taking the time to identify potential risks lays the foundation for successful risk mitigation in the following steps.

Now that you’ve pinpointed potential risks, it’s time to analyze them.

Analyzing procurement risks involves two key factors.

First, you want to investigate the root causes as to why a risk occurred in the first place.

Second, you’ll assess both the likelihood of a risk occurring and the impact it could have on your procurement operations or the business overall.

Let’s start by examining why risks emerge.

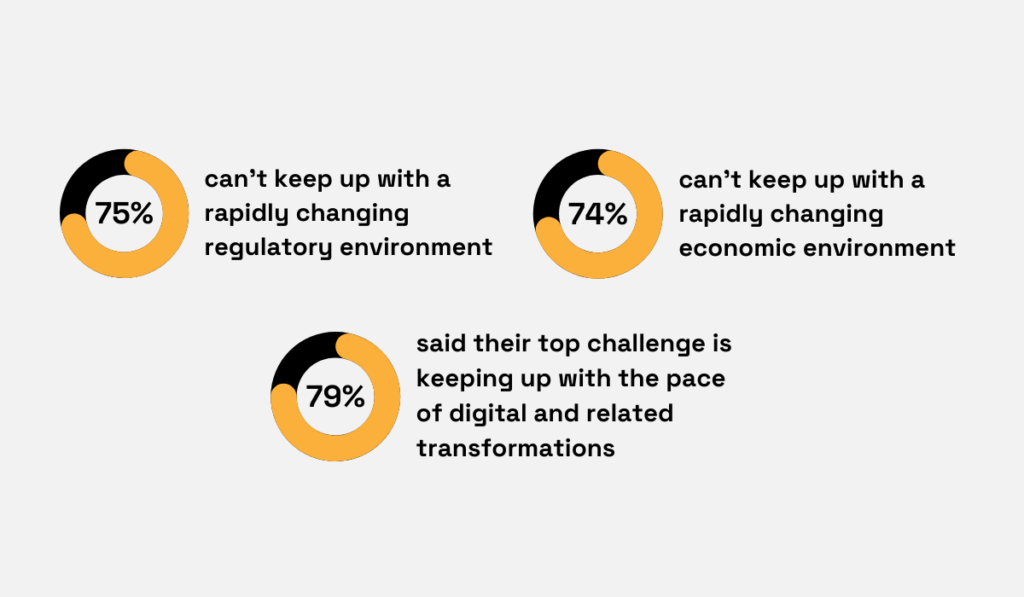

While the reasons are varied, it’s helpful to consider the findings of experts in the field.

For instance, a PwC survey of over 3,500 global risk executives highlights the top challenges they face in risk management.

Illustration: Veridion / Data: PwC

Consider whether some of these external factors might be the culprit in the risks your team has identified.

Perhaps changing regulatory and economic conditions have led to supply chain disruptions or price volatility.

Or, maybe a lack of investment in modern procurement software has made your processes inefficient and error-prone.

After analyzing each risk and trying to determine its potential cause, focus on metrics such as the likelihood of occurrence and the impact of each risk.

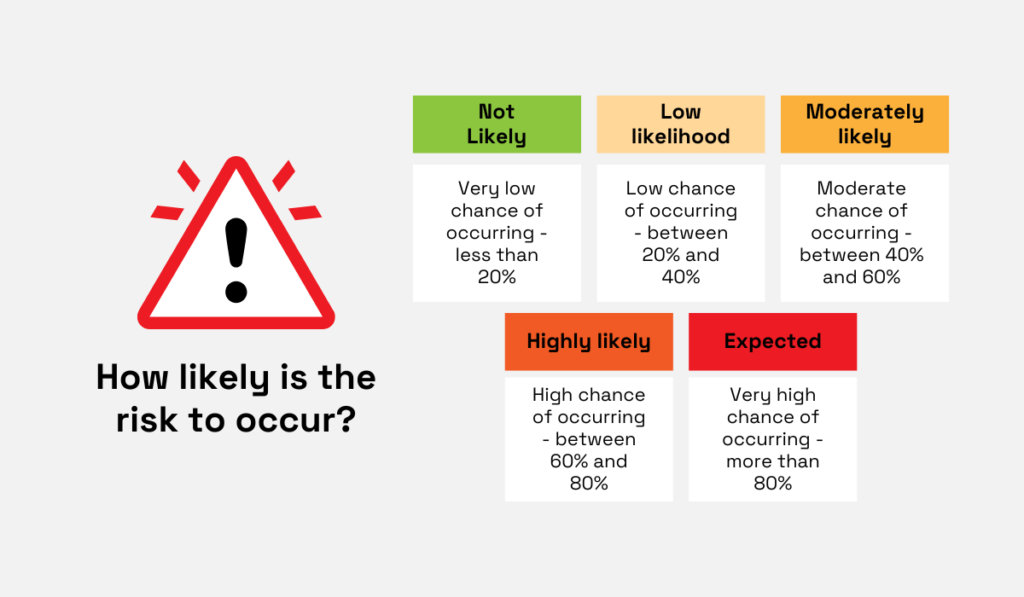

Let’s start with likelihood.

Source: Veridion

This metric is essentially the probability of a risk actually occurring.

Sorting risks into categories like the ones shown above helps you prioritize mitigation efforts, focusing your energy on the most probable threats.

Risk impact, on the other hand, refers to the potential damage a risk could cause if it were to materialize, and could range from negligible to severe.

The impact could be disruptions to your procurement process, financial losses, damage to your company’s reputation, or even legal repercussions.

With thorough risk analysis, you ultimately gain a deeper understanding of the threats your procurement process faces.

Let’s now turn to a crucial step—determining your risk priorities.

By this point, you’ve meticulously analyzed your risks, assigning likelihood and impact scores to each.

The next phase is to carefully review this list of risks and establish a clear hierarchy of which ones demand the most urgent attention.

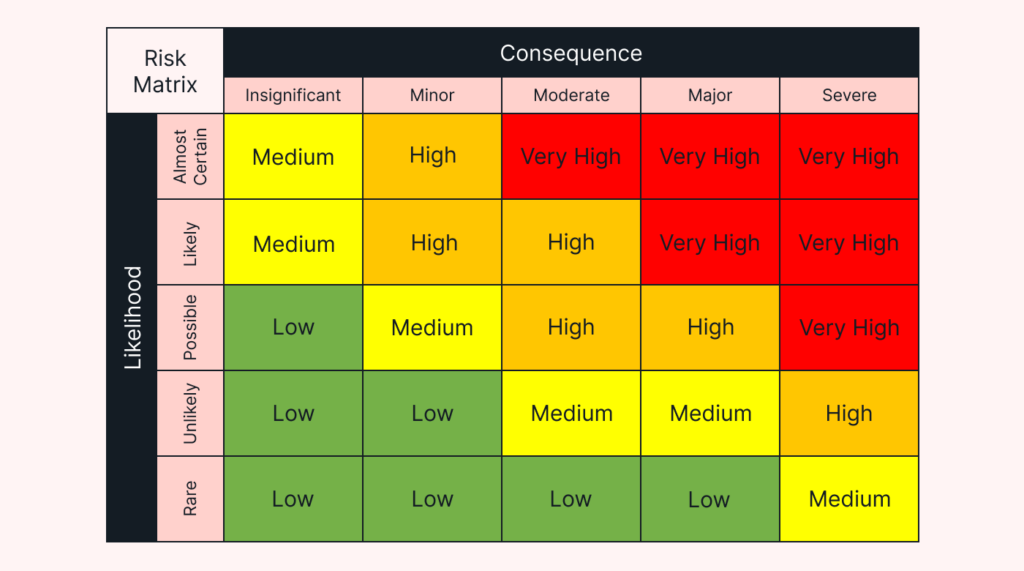

A widely used tool for risk prioritization is the risk matrix, illustrated below.

Source: Motion

This matrix visualizes the relationship between risk impact (or consequence) and risk likelihood.

By considering these two factors, risks can be assigned priority levels—often labeled as low, medium, high, or even extreme.

While there are no hard-and-fast rules for classification, some general guidelines can help.

Risks that are very likely to occur should typically be classified as high priority, even if their impact is minor.

Since they’re probable, they pose a consistent threat that can accumulate over time.

Conversely, risks that are exceptionally rare likely fall into the low-priority category, even if their severity is high.

It’s important to treat the risk matrix as a guide, though, and not an immutable rulebook.

There will always be exceptions to consider.

For example, you might choose to proactively address a risk with catastrophic potential for the business, such as major supply chain disruptions related to geopolitical events, even if its immediate likelihood is deemed low.

Always try to consider both the specific threat to your procurement process and the potential ripple effects on your organization as a whole.

Remember, procurement goals are closely tied to overall business goals, but there still are differences.

| Goal | Business Goals | Procurement Goals |

|---|---|---|

| Financial | Overall profitability, revenue growth | Cost savings, budget adherence |

| Operational | Product/service quality, market responsiveness, innovation | Supplier reliability, on-time delivery, process efficiency |

| Strategic | Long-term vision, competitive advantage | Sustainable sourcing, ethical supplier relationships, risk resilience |

All in all, striking a balance between business and procurement goals and considering different risk factors is key to effective risk prioritization.

With your risk priorities established, it’s time to focus on developing mitigation strategies.

The goal here is to devise ways to reduce, avoid, or transfer the impact of the highest priority risks.

Remember, it’s usually advisable to begin with the most critical risks and gradually work your way down the priority list as resources allow.

The specific mitigation strategy will vary depending on the type of risk.

Let’s consider some common procurement risks and mitigation strategies, illustrated in the following table.

| Risk | Mitigation Strategy |

|---|---|

| Price volatility | Negotiate fixed-price contracts or implement hedging strategies. |

| Regulatory changes | Maintain active communication with legal and compliance teams. Diversify supplier base across different regulatory jurisdictions. |

| Supplier risk | Develop a pool of pre-qualified backup suppliers. Conduct regular supplier reviews. |

| Data breaches | Implement robust cybersecurity measures and encrypt sensitive procurement data. |

| Fraud or unethical behavior | Establish clear approval processes and conduct regular internal audits. |

Consider price volatility, which arises when the prices of critical materials or services fluctuate unpredictably, threatening your budget projections.

To mitigate this risk, you might negotiate fixed-price contracts with suppliers or utilize hedging strategies to lock in favorable prices in advance.

Another important risk to consider is supplier risk, which can cause significant disruptions to your operations.

Some mitigation strategies focus on outdated processes for vetting and evaluating suppliers.

This focus is not by chance. Take a look at this statistic from Prevalent illustrated below.

Illustration: Veridion / Data: Prevalent

Relying on outdated methods for supplier assessment can expose your organization to hidden risks.

One solution is adopting a specialized supplier sourcing tool like Veridion.

Veridion’s global database, updated weekly with the latest supplier information, enables you to quickly identify reliable partners.

Additionally, our advanced search API allows you to locate suppliers meeting your specific criteria, empowering you to make data-driven decisions and lower the likelihood of supplier-related problems.

Source: Veridion

Veridion plays a crucial role in mitigating risks.

Its real-time alerts give you the foresight to anticipate potential material shortages or changes in supplier status, allowing you to proactively pursue alternative sources or make necessary adjustments in your approach.

By carefully considering the specific characteristics of each risk, and taking both preventive and reactive measures, you can significantly reduce the vulnerability of your procurement process to disruptions.

After developing mitigation strategies, the next step is to implement risk controls and measures to keep a watchful eye on procurement risks.

This involves establishing processes, procedures, and metrics to ensure ongoing monitoring and management of potential threats.

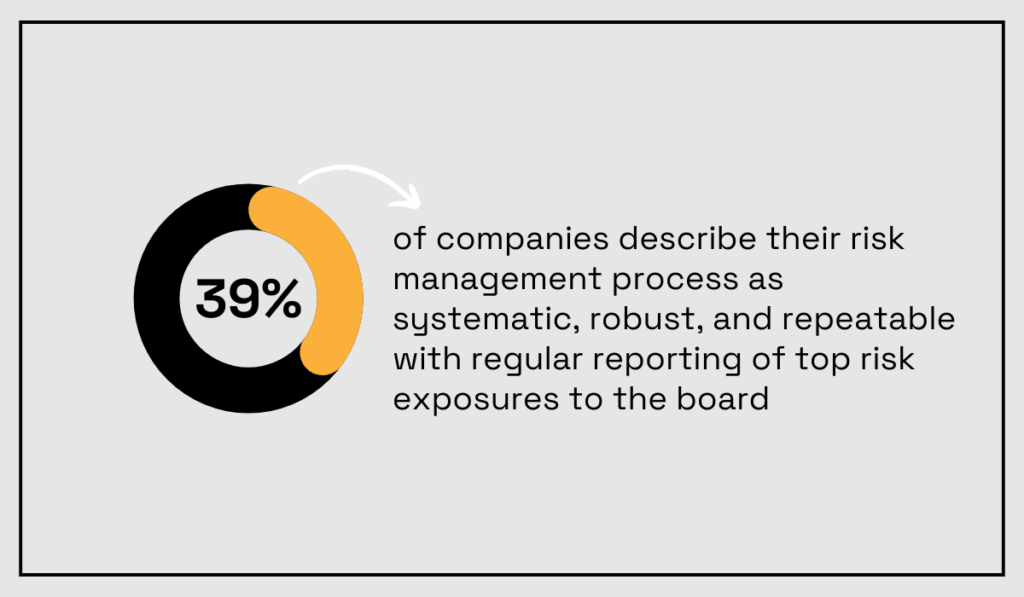

A key challenge in risk control is ensuring consistent adherence to risk management protocols throughout the organization.

According to AICPA’s State of Risk Oversight report, less than 50% of organizations describe their risk management processes as formal and structured.

Illustration: Veridion / Data: AICPA

This could be due to factors like lack of awareness, unclear risk management protocols, or poorly established criteria and metrics.

This last point is a crucial one, as well-defined key performance indicators (KPIs) are essential for tracking the effectiveness of your risk controls and communicating risk-related insights to stakeholders.

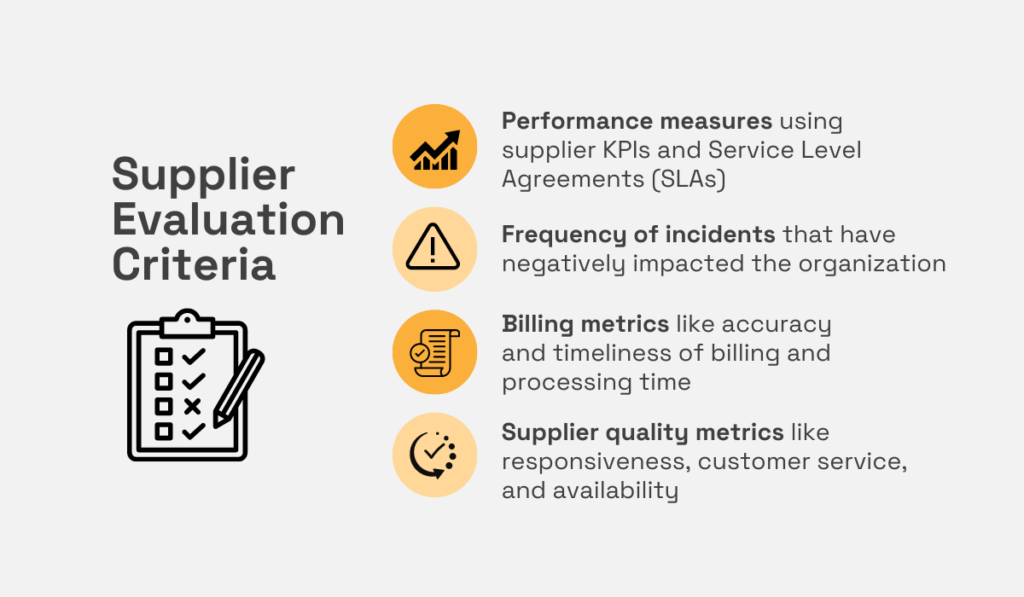

Let’s consider the example of supplier risk evaluation.

Some key KPIs to track could include the ones illustrated below.

Source: Veridion

From performance metrics like on-time delivery rate and defect rate to the percentage of suppliers adhering to service level agreements (SLAs), regular monitoring of these indicators creates a robust risk control framework.

These principles apply to many procurement processes.

Similar KPIs and criteria should be established for different procurement areas like contract management, budget adherence, or regulatory compliance.

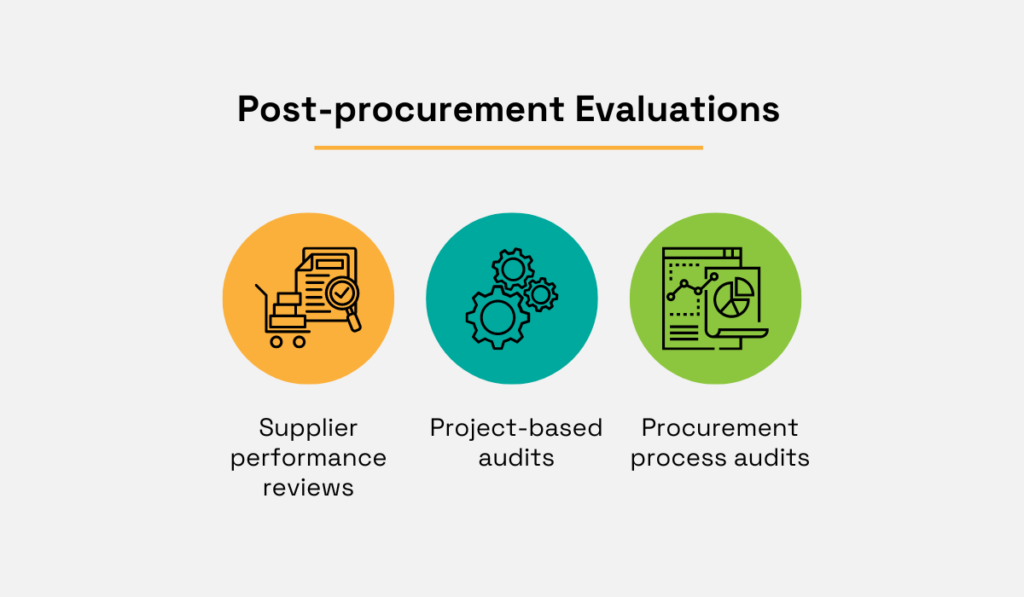

Another part of risk control is conducting post-procurement evaluations and audits.

These evaluations can take various forms, as illustrated below.

Source: Veridion

We already touched upon supplier performance evaluations.

Project-based audits, on the other hand, offer a deeper look at a specific procurement project, helping identify bottlenecks, inefficiencies, or areas where risks were not adequately managed.

Finally, procurement process audits ensure procedures are being followed, while at the same time identifying inefficiencies. irregularities, and potential occurrences of fraud.

By implementing risk controls, tracking relevant KPIs, and conducting comprehensive post-procurement evaluations, your procurement team builds a robust system for ongoing risk management.

The final step involves planning and committing to a continuous improvement strategy.

This philosophy essentially means actively learning from past experiences, identifying areas for refinement, and integrating those lessons into future procurement practices to further strengthen risk resilience.

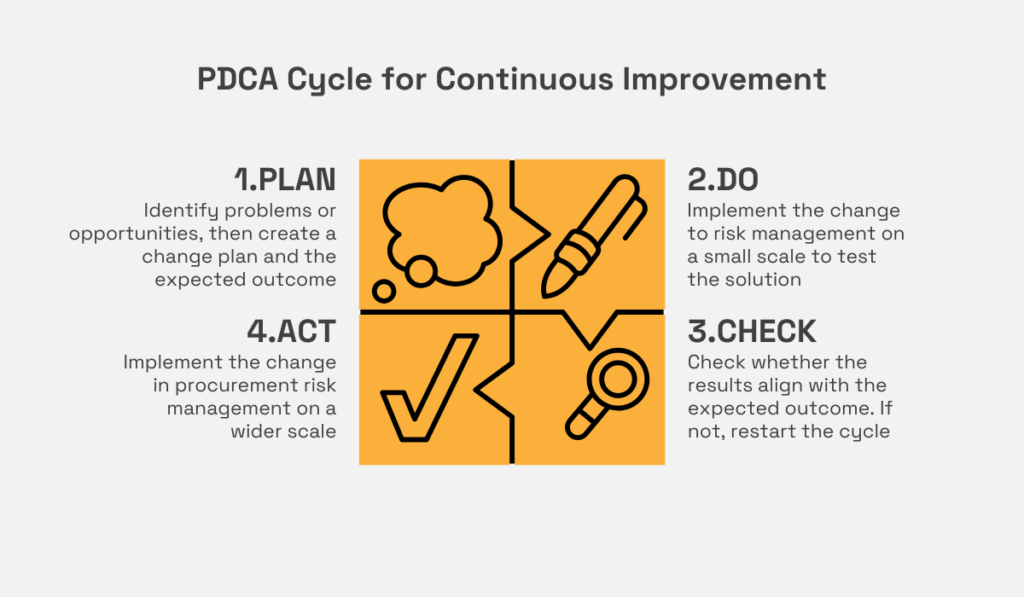

A common framework that embodies this continuous improvement approach is the Plan-Do-Check-Act (PDCA) cycle.

Source: Veridion

The PDCA cycle facilitates continuous improvement in risk management by planning strategies based on past lessons, implementing and monitoring those plans, and using the data to refine your approach and share best practices.

The beauty of the PDCA cycle lies in its iterative nature.

It recognizes that risk management isn’t a one-and-done activity, but rather an ongoing journey of improvement and adaptation.

It’s crucial to remember that continuous improvement isn’t just a procurement team responsibility, as fostering a company-wide culture of optimization and improvement maximizes its benefits.

Consider the potential advantages of collaboration:

Collaborative problem-solving brings diverse perspectives to the table, helping identify risks from a broader viewpoint and fostering a shared sense of responsibility for success.

So, you should aim for open communication channels, feedback mechanisms, and regular engagement of the procurement team with stakeholders across different departments.

By embracing continuous improvement as an ongoing process, you equip your organization to proactively adapt, anticipate, and respond to evolving risks, thereby enhancing the long-term success of your procurement operations.

In this article, we’ve explored the essential components of procurement risk management.

From identifying and analyzing potential risks to establishing processes for prioritization and mitigation, we’ve outlined the crucial elements of a robust plan.

Also, we’ve discussed how to implement key risk controls and why focusing on continuous improvement is important.

What this means for you is that, armed with this knowledge, you can create a risk management strategy that aligns with your organization’s specific needs.

By applying these principles, you’ll minimize procurement operational disruptions and safeguard your business through informed decision-making.

Remember, proactive risk management is an ongoing journey.

So stay vigilant and adaptable, and continuously reassess your approach to ensure success.