6 Surefire Ways to Maximize Procurement Savings

Saving money in procurement is always a top concern for chief procurement officers (CPOs) and their teams.

However, recent crises in the economy, health, and geopolitics have made it more urgent for companies to rethink and strengthen their cost-saving efforts.

Some studies even show that the problem with savings on procurement is often not how to achieve them, but how to keep them.

In this article, we’ll cover six ways you can achieve and sustain those savings.

So, if you want to make your department more successful and more resistant to various disruptions, keep reading.

Procurement teams should combine data from various sources.

This will let them detect spending patterns, find savings opportunities, and make better choices in the future.

So, why is data consolidation crucial?

Because there is a lot of procurement data to check, and new data is being generated quickly.

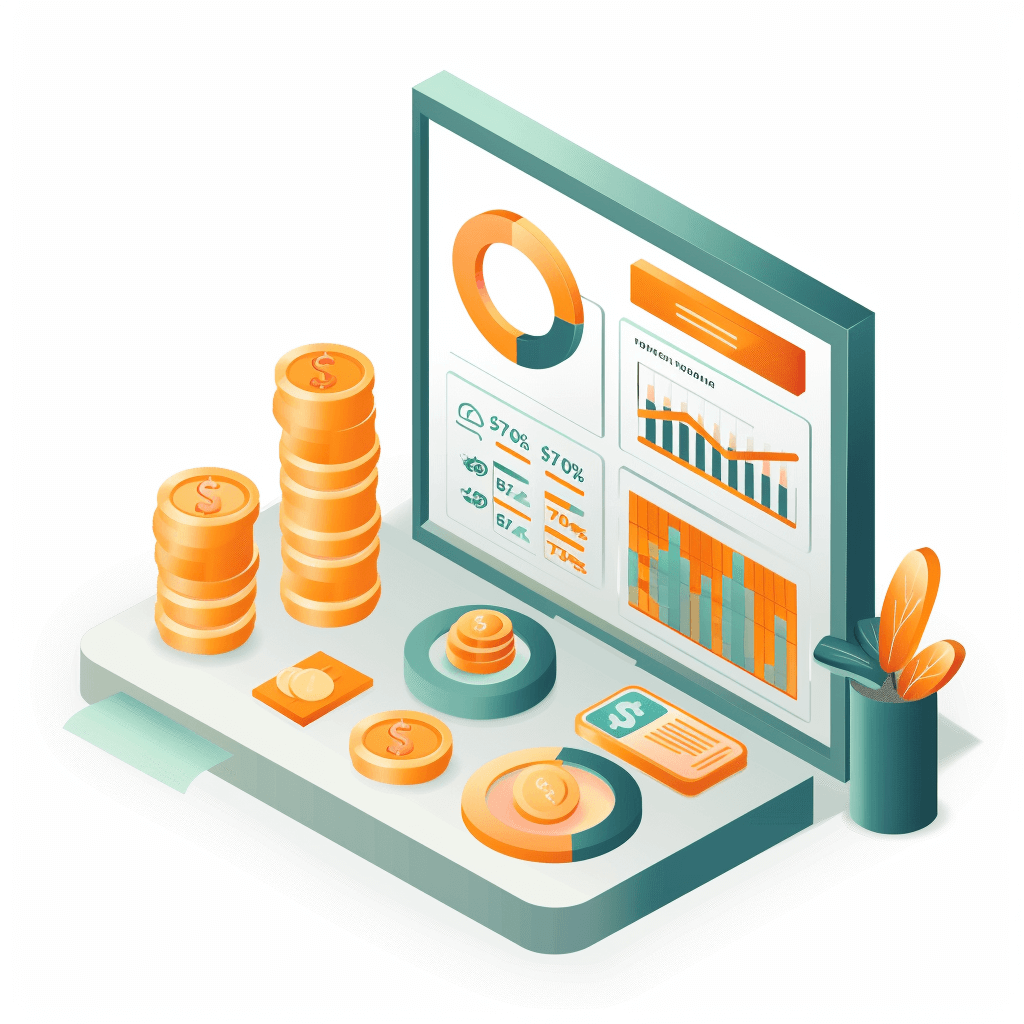

This often leaves procurement teams grappling with issues like poor data quality, lack of standardization, and data silos.

Source: Veridion

All these issues make it hard for teams to access and combine procurement data coming from inside and outside the company.

Unfortunately, that hinders comprehensive analysis and extraction of actionable insights, potentially leading to:

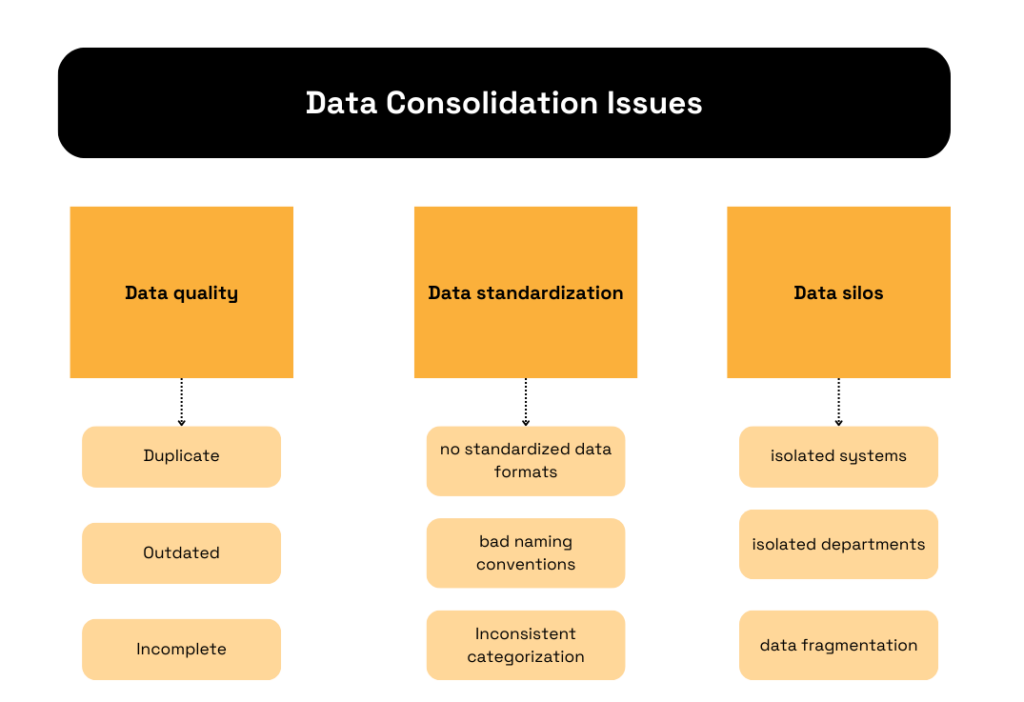

This is confirmed by different data management studies and surveys, where data professionals pointed out the same concerns and challenges.

Illustration: Veridion / Data: TMMData / Informatica

The stats on the left show that companies still have a lot of room for improvement in data consolidation while the data on the right highlight the increasing complexity involving data management.

The number of sources managed and the extent of the above-mentioned issues impede a procurement team’s ability to analyze data and extract meaningful insights about potential cost reductions.

So, how can your company tackle these data consolidation issues?

Here are five ways to achieve data consolidation that will enable effective data analysis and help generate procurement savings:

| Invest in data integration tools | → to break down data silos |

| Standardize data formats | → to enhance data consistency |

| Train procurement staff | → to use new tools and practices |

| Regularly review and update data | → to ensure data accuracy and relevance |

| Foster interdepartmental collaboration | → to improve data sharing efficiency |

As expected, consolidating a lot of data sets typically requires leveraging data integration tools.

Powered by machine-learning algorithms and supported by cloud data storage repositories (data warehouses and data lakes), these tools enable seamless integration of data from disparate sources, including ERP systems, supplier databases, and financial records.

Moreover, they assist in standardizing data formats and taxonomy while simultaneously cleansing and reformatting data.

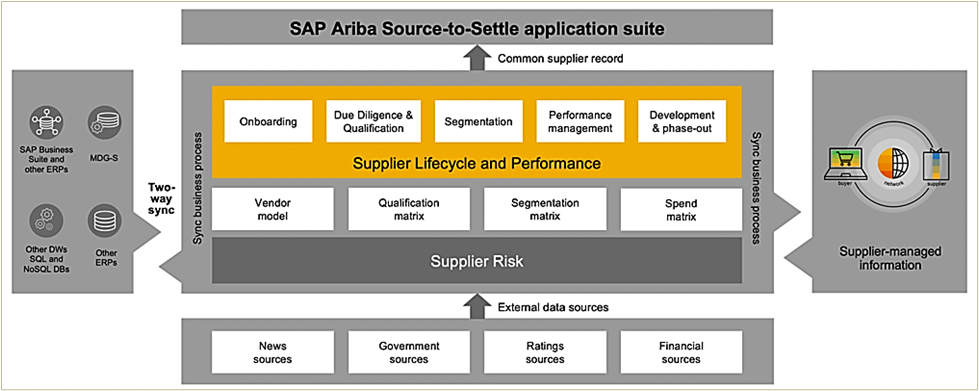

Source: SAP

This process addresses common challenges such as data inaccuracy, inconsistency, or duplication.

Once a single source of accurate procurement information is set up, this data becomes invaluable for analysis and use across company departments. Especially for the procurement team.

In addition to data integration and standardization, another two crucial aspects of good data consolidation are:

Simply put, procurement teams need to fully understand the potential of new tools, feel empowered to utilize them, and be encouraged to collaborate with colleagues across the organization.

Finally, it’s important you regularly review and update procurement data. For that, you can use third-party big data platforms to enrich your company’s data sources and improve data accuracy and relevance.

Another effective way to maximize procurement savings is to set up spending approval workflows.

You want to make sure that purchases are approved by the appropriate personnel to prevent anything unauthorized or untracked (maverick, rogue, or tail spending).

According to some sources, maverick spending can account for as much as 80% of company expenditure, leading to several detrimental consequences:

To prevent these outcomes, your procurement team (in collaboration with senior management and the finance department) should define spending thresholds and approval hierarchies.

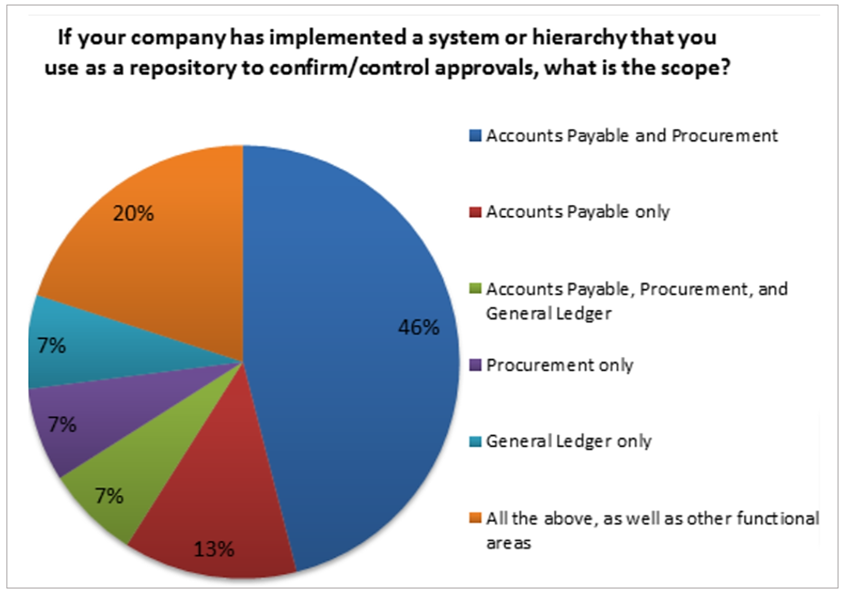

As illustrated in the image below, a survey showed that companies implementing such measures mostly prefer to combine accounts payable and procurement in such systems.

Source: Peeriosity

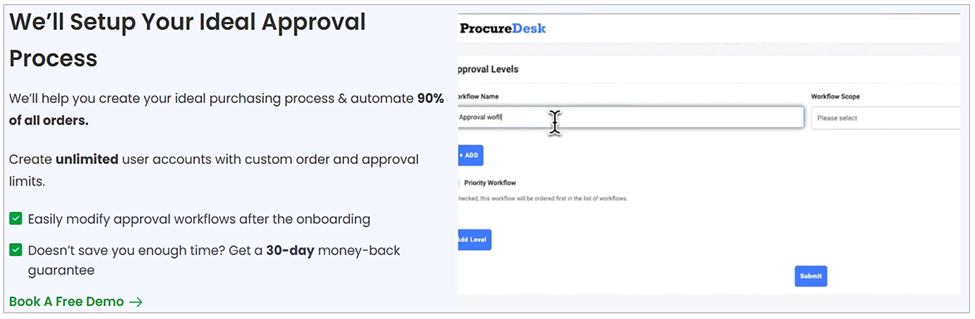

To set up effective spend approval workflows, companies should use technology. For example, procurement management software.

Such platforms enable automated routing of purchase requests based on predefined rules and approval hierarchies, streamlining the approval process, and reducing delays.

Source: ProcureDesk

By defining spending limits and approval hierarchies and automating the approval process, procurement teams can prevent unnecessary expenditures and promote accountability.

A practical example involves lower-value purchases being approved by department managers, while larger ones require sign-offs from higher-level executives or budget holders.

Additionally, regular reviews and updates to approval workflows are essential to adapt to evolving organizational needs and regulatory requirements.

Given the number and potential impacts of procurement risks, developing strong risk management practices is crucial.

It will maximize your procurement savings initiatives and make sure they are not derailed.

Say a company negotiates more favorable prices with a specific supplier to save costs. Any disruption in that supplier’s operations (bankruptcy, own supply issues, etc.) can make its cost-saving initiative inefficient.

Moreover, if a company relies heavily on that supplier for a critical component, such disruption could lead to:

Naturally, these consequences and their related costs will further undermine the initially intended cost-saving targets.

That’s why it’s imperative to have robust risk management practices in place to identify, assess, and mitigate such risks, ensuring the sustainability of procurement savings.

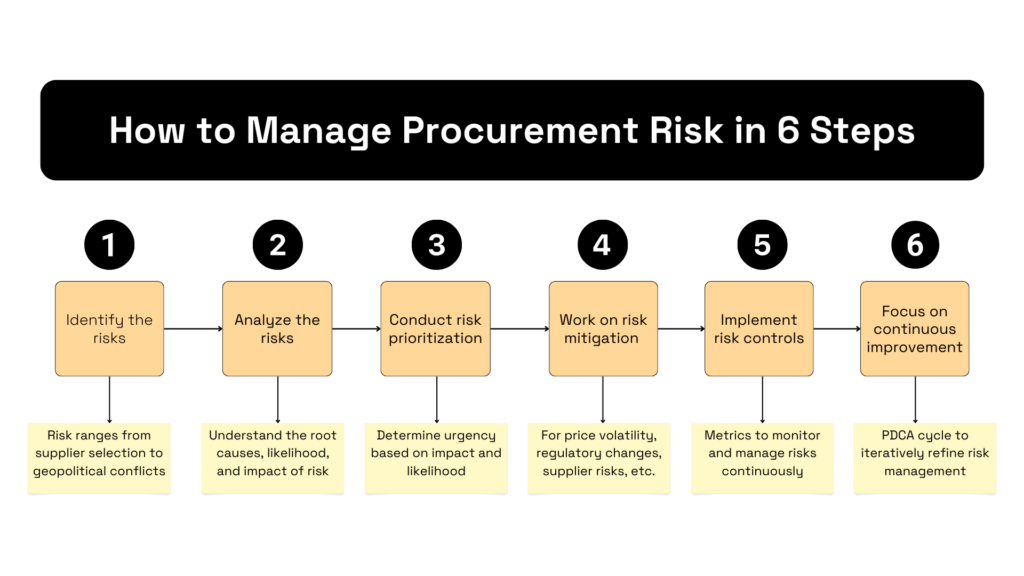

You can see a visual representation of six risk management process steps below:

Source: Veridion

And you can read more about each step in our article on that topic.

It’s also worth noting that many external, supplier-related risks can be best mitigated during initial supplier selection.

Simply put, a thorough supplier evaluation and risk assessment enables your procurement team to select reliable, low-risk suppliers with their own robust risk management practices.

Of course, things change, and new risks emerge, so risk controls and continuous monitoring are a must.

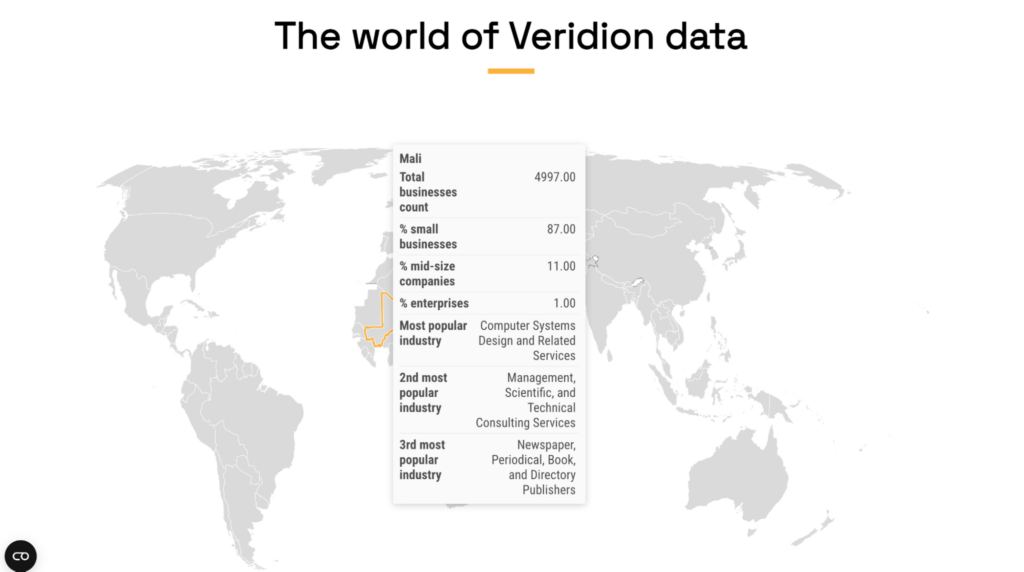

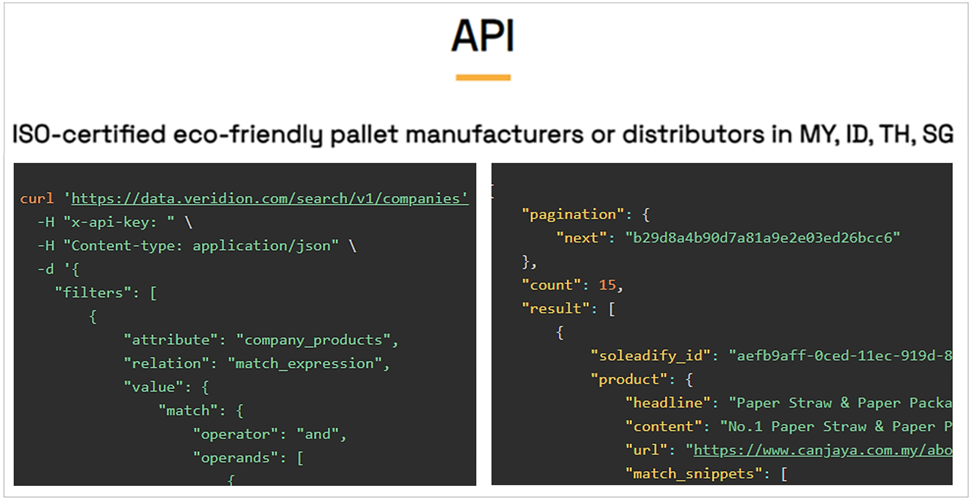

To simplify the processes of selecting new suppliers, searching for alternative ones, and monitoring risks related to existing suppliers, you can consider using our specialized supplier-sourcing tool, Veridion.

With Veridion, you get access to a global database of suppliers, updated weekly, and powerful search APIs that seamlessly integrate with your procurement management tools.

Source: Veridion

This allows you to identify suppliers meeting your specific criteria and create a shortlist of potential suppliers in a few seconds.

Moreover, you can do that by inputting your search queries in a natural language.

For example:

Source: Veridion

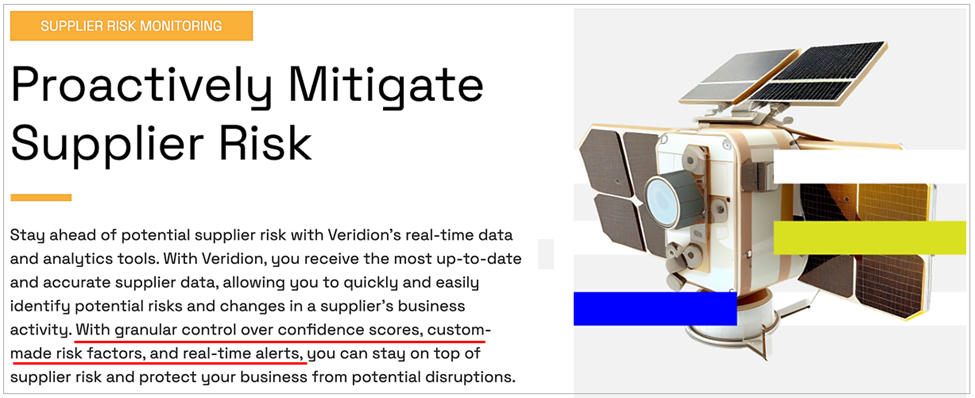

You can also use Veridion to assess potential and current suppliers against a slew of risks:

For your current suppliers, you can establish a list of custom-made risk factors and receive real-time alerts when they’re detected.

That will allow you to anticipate potential risks and take preemptive actions to mitigate their impact on procurement operations.

Source: Veridion

Developing these risk management practices and using appropriate tools empowers procurement teams to mitigate various procurement-related risks.

In doing so, they can both help maximize cost savings and ensure their preservation.

Another efficient way to maximize procurement savings is to capitalize on economies of scale.

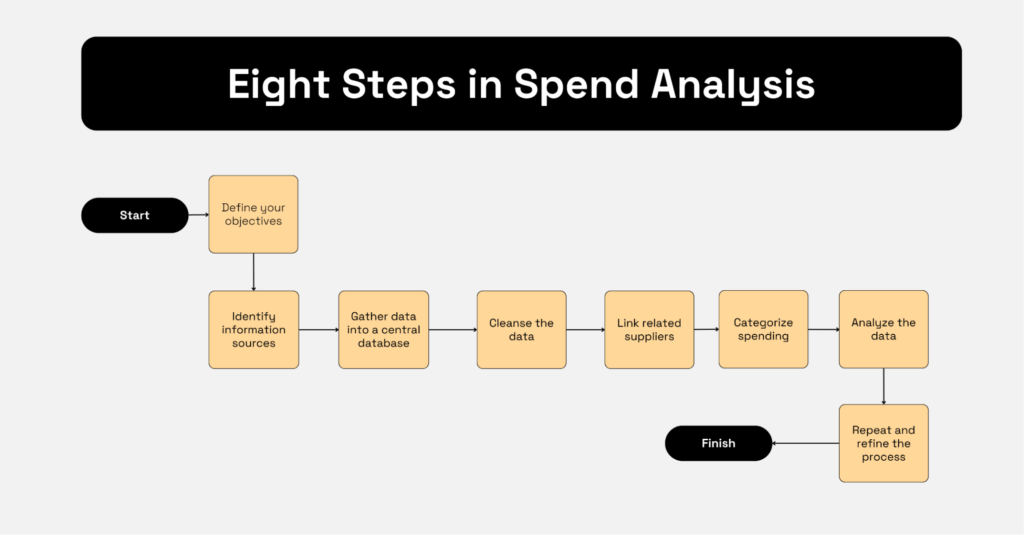

To uncover opportunities for volume discounts, first consolidate your spend data from various departments and perform comprehensive spend analysis.

Source: Veridion

Spend analysis should enable you to:

It provides visibility into the company’s spending patterns, enabling better control over categories and discovery of purchase consolidation and volume discount opportunities.

Now, when consolidating purchases/suppliers, you can use your aggregated purchasing power to choose the most competitive supplier and agree on favorable volume discounts.

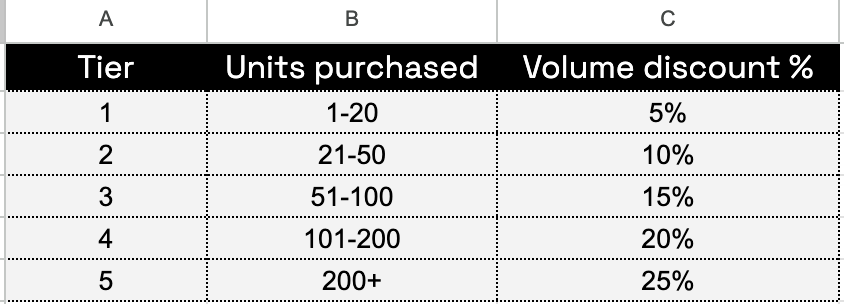

To illustrate this concept, here’s an example of a tiered volume discount structure typically offered by many vendors:

Source: Veridion

While the number of units purchased and the percentage of volume discount will vary, the principle remains the same—the more you buy, the more you save.

The supplier might not offer such volume discounts by default, but your team can try to negotiate them based on purchase projections.

Then, you’ll maximize cost savings. But there are also other terms you can negotiate.

Early pay discounts, flexible payment terms, and guaranteed service levels all enable procurement teams to generate additional savings.

These savings can also arise from reduced administrative costs, enhanced supplier performance, or increased operational efficiency.

Apart from negotiations during supplier selection, you can achieve them throughout the whole relationship lifecycle.

Here are some situations when contract (re)negotiations should be considered:

Each of these scenarios presents an opportunity for procurement teams to optimize contract terms and drive cost savings.

For instance, if a major hurricane disrupts your supplier’s operations, renegotiating the contract to diversify production locations or set up alternative supply routes can help minimize additional costs associated with sourcing from affected areas.

Another example involves software license contracts or service agreements being renegotiated to integrate new software systems into production/administrative processes.

By renegotiating such contracts, companies can realize cost savings through increased operational efficiency, reduced manual errors, and optimized resource allocation.

Of course, all negotiations have (at least) two sides, so be ready to compromise.

In any case, transparent and fair supplier relationships can significantly help you when trying to negotiate improved contract terms.

Regular audits of your processes, contracts, invoices, and supplier performance are essential for maintaining efficiency and maximizing cost savings.

By conducting regular audits, you can identify discrepancies, errors, or inefficiencies that may be costing the company money.

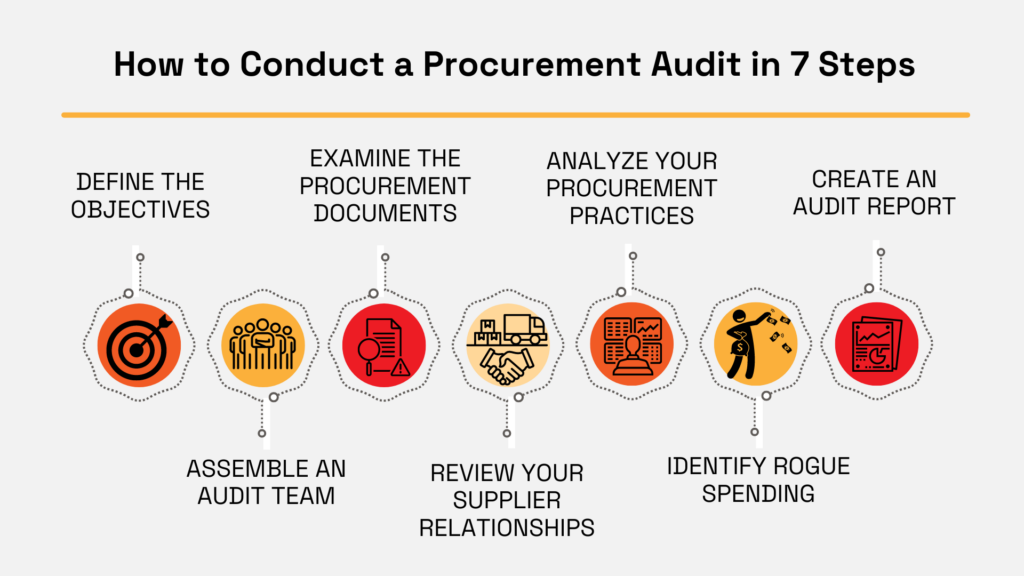

Here is how to conduct a procurement audit in seven steps:

Source: Veridion

As illustrated, the audit process starts by clearly outlining the goals and scope of the audit.

Then, an audit team is assembled from individuals with expertise in procurement, finance, and operations.

This is followed by reviewing contracts, purchase orders, invoices, procurement policies, and approval procedures for accuracy and compliance, as well as assessing supplier performance to evaluate the effectiveness of existing relationships.

Next, procurement processes and workflows are analyzed to recognize areas for improvement and identify instances of rogue/maverick spending (just like during data consolidation and spend analysis).

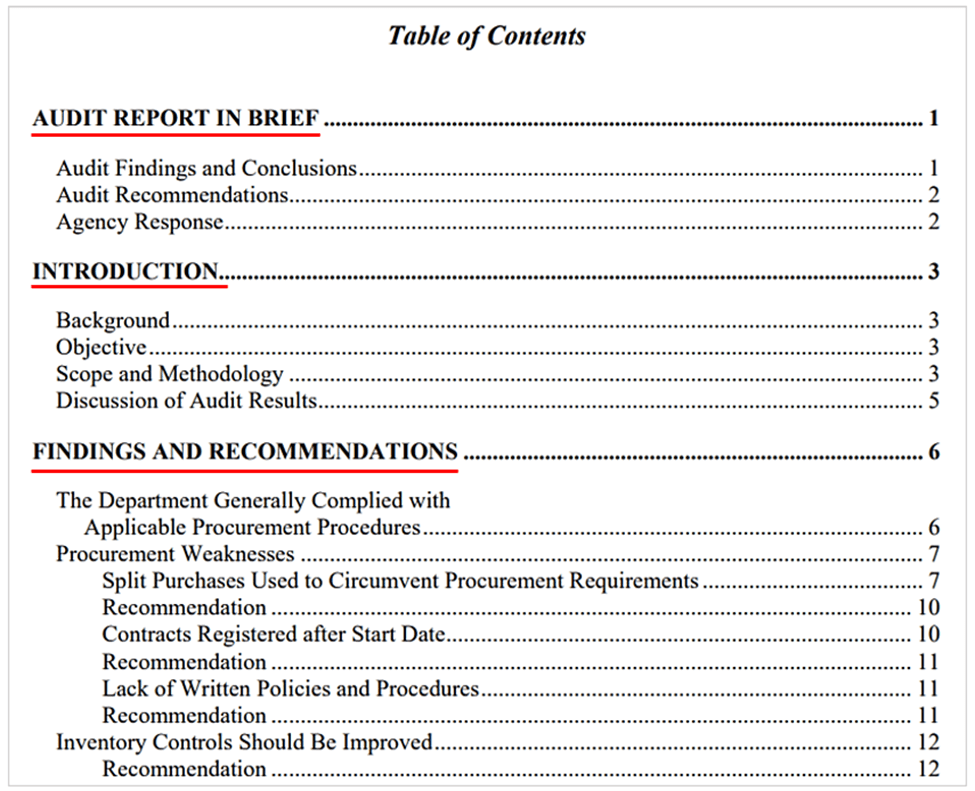

Lastly, a procurement audit report is created where audit findings and recommendations for corrective actions are documented.

Source: nyc.gov

Ultimately, such reports enable relevant company decision-makers to analyze audit findings and implement corrective actions that allow for greater savings.

As you can see, there are ways to maximize savings in procurement. But all of these tactics hinge on your team’s ability to comprehensively analyze procurement data.

Therefore, adopting tech that helps you do that and finding efficient methods to do so, is essential.

It is a surefire way for achieving and sustaining cost savings in procurement.