Top 5 Challenges in Strategic Procurement

Simply put, strategic procurement is better procurement that aims to ensure your purchasing practices align with your strategic business goals.

This involves buying products and services from reliable suppliers with the fewest risks possible and from suppliers that are sustainable and ethical, instead of focusing on buying products for the lowest price.

However, this approach to procurement requires being data-driven, thoroughly evaluating suppliers you work with, knowing when and how to balance cost and quality, and adopting new technologies that will enable all of this.

At the same time, all of the above are the challenges that procurement departments face on their way to strategic procurement.

Today, we will take you through these challenges and give you some valuable tips on how to overcome them successfully.

Let’s get going.

Strategic procurement depends heavily on understanding your suppliers’ behaviors.

But without insight into their operations, you face significant hurdles.

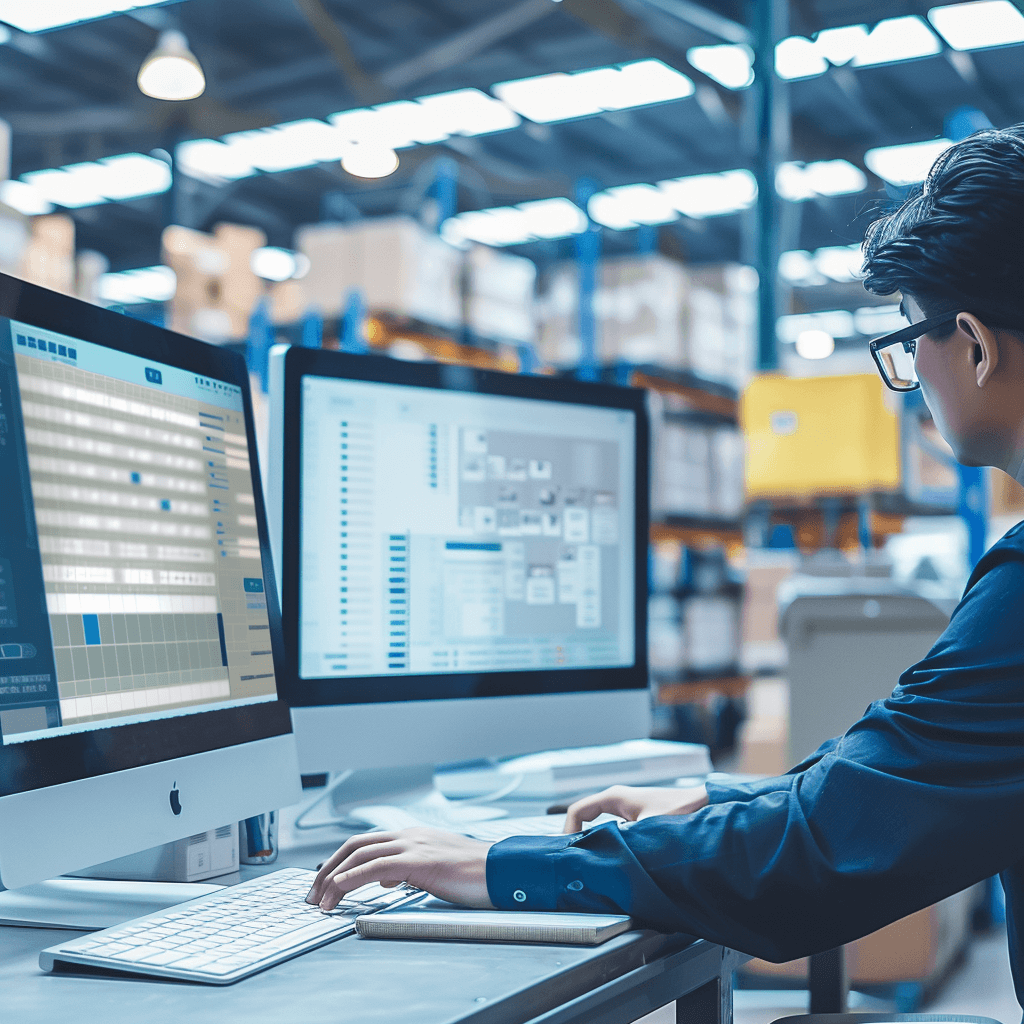

This is an alarming reality for a large number of companies who report having a lack of clear visibility into their primary suppliers’ performance, according to KPMG.

Illustration: Veridion / Source: KPMG

Limited visibility into supplier operations—including financial stability, production capacity, and overall performance—creates numerous problems.

This gap in knowledge hinders effective procurement risk management, quality control, and performance evaluation, leading to inefficiencies and vulnerabilities in the supply chain.

Additionally, poor supplier visibility can derail your sustainability goals, which are vital for strategic procurement.

Without insight into suppliers’ environmental, social, and governance (ESG) practices, making informed decisions becomes impossible.

Research shows that 35% of companies cite poor visibility into suppliers as a barrier to improving supply chain sustainability.

And given that 78% of businesses face increased demand for sustainable goods and services, addressing this issue is more urgent than ever.

Illustration: Veridion / Source: Procurious

Fortunately, advanced analytics tools and supplier management platforms offer solutions to enhance supplier visibility.

By adopting these technologies, you can track and measure supplier performance, gain deeper insights into their operations, and mitigate related risks.

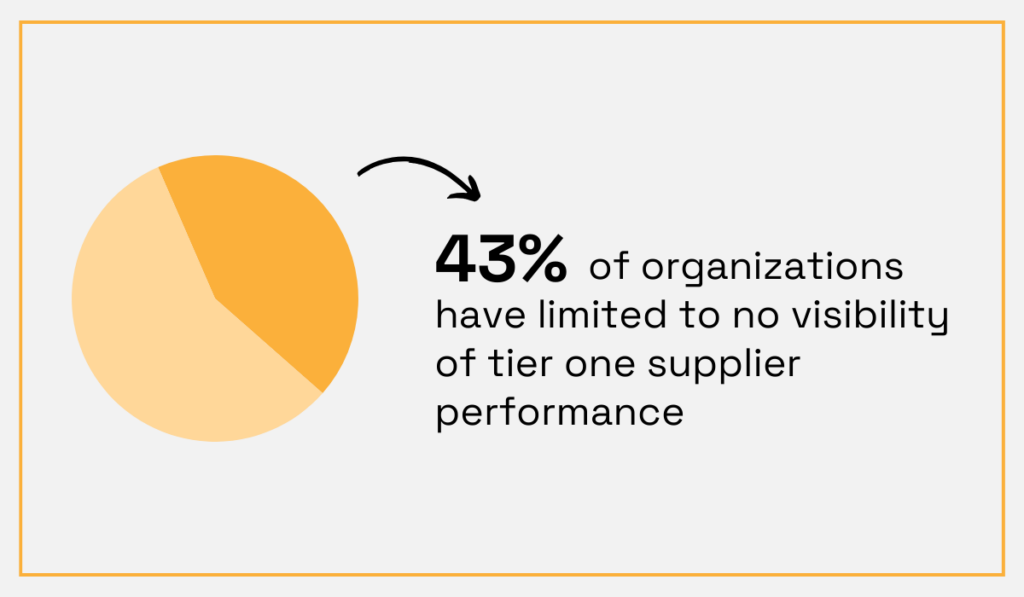

One such advanced data analytics tool is our very own supplier sourcing enabler, Veridion.

Veridion offers access to the largest supplier database, comprising data on tens of millions of global suppliers.

Source: Veridion

Veridion’s search APIs integrate seamlessly into your systems, allowing you to find suppliers based on specific criteria, such as product specifications, certifications, and ESG standards.

This turns a supplier search that once took weeks into a process completed in minutes.

But here is how Veridion can also improve your visibility into suppliers’ operations: by sending real-time alerts about changes in supplier activities.

Source: Veridion

For instance, if a supplier loses an important certificate, Veridion will notify you.

This way, you can react immediately, prevent potential risks that losing this certificate would have on you, and ensure the continuous integrity of your operations.

In summary, poor visibility into supplier operations is a pressing challenge that affects a large number of companies.

However, with the right tools in your hands, you can overcome this obstacle and drive strategic procurement and sustainability forward.

New tools can greatly enhance your procurement processes, making them more strategic.

However, adopting these tools involves change—and people often resist change.

This is another obstacle in strategic procurement.

But the resistance isn’t just about adopting new tools.

It often extends to changing suppliers, especially if there are long-standing relationships in place, or if people are reluctant to accept new procurement methods.

Imagine working with the same suppliers for years, and now you’re asked to consider alternatives.

It’s natural to feel uneasy about disrupting these familiar partnerships, even for strategic gains.

But why does this resistance persist?

Here are some common reasons:

| Job security concerns | Team members may fear that new procurement methods will make their roles obsolete or less relevant. |

| Doubts about effectiveness | Without concrete evidence of benefits, some may hesitate to embrace changes and prefer to stick with the tried-and-tested methods they’re familiar with. |

| Comfort with familiar practices | Changing suppliers or adopting new procurement methodologies requires stepping out of the comfort zone, and this can be daunting for some. |

Yes, these are all valid concerns.

However, in some cases, resistance to change may stem from concerns about uncovering unlawful or unethical practices within the organization.

Employees may fear the consequences of exposing such issues and resist changes that could highlight wrongdoing.

That’s why it’s even more important to implement change.

But it goes without saying that you can’t just force it on people.

You have to take a multifaceted approach and do the following:

The bottom line is: you should address these concerns and involve procurement professionals in the change process, instead of just implementing change abruptly.

When you explain why the change is necessary, how it will benefit them personally, and when you train them properly, your procurement colleagues will accept the change more easily—and more successfully, too.

Building and maintaining strong relationships with suppliers is essential for strategic procurement, but it’s not without its challenges.

Supplier relationship management demands ongoing effort and investment of time and resources.

You may face hurdles such as negotiating contracts, resolving conflicts, and aligning goals and expectations between your organization and its suppliers.

Ian Milligan, Strategic Sourcing Team Lead at Coupa Software, highlights additional challenges like communication issues and ensuring compliance with contract terms.

Illustration: Veridion / Source: LinkedIn

Luckily, all of the above can be solved with one solution: implementing supplier relationship management software.

This tool enhances connectivity between procurement teams and suppliers by centralizing communication, data management, and collaboration efforts.

Let’s see how by diving into some key features of such software:

| Contract management | SRM software centralizes contract data, tracks key milestones and deadlines, and ensures compliance with contract terms and conditions, making contract management more efficient. |

| Performance monitoring | It enables real-time monitoring of supplier performance metrics, allowing you to identify potential issues and opportunities for improvement in time. |

| Supplier collaboration tools | These tools enable faster communication, document sharing, and task management between procurement teams and suppliers while also giving both sides more transparency. |

| Supplier survey for feedback | This feature enables you to gather feedback from suppliers regarding their experiences, performance, and areas for improvement. By collecting feedback systematically, you can identify opportunities to enhance collaboration and address any issues or concerns suppliers raise. |

Finally, Emely Bonife, Supply Chain Manager at Manila Hearing Aid, reminds us of one more crucial aspect of supplier relationship management:

Illustration: Veridion / Source: LinkedIn

When you adopt this mindset—that your suppliers are your partners, rather than just occasional transactions—the overall supplier management will become easier, too.

All in all, by having the right tools for supplier relationship management and treating suppliers as valuable contributors, you will improve collaboration and ensure stronger and more productive partnerships with your suppliers.

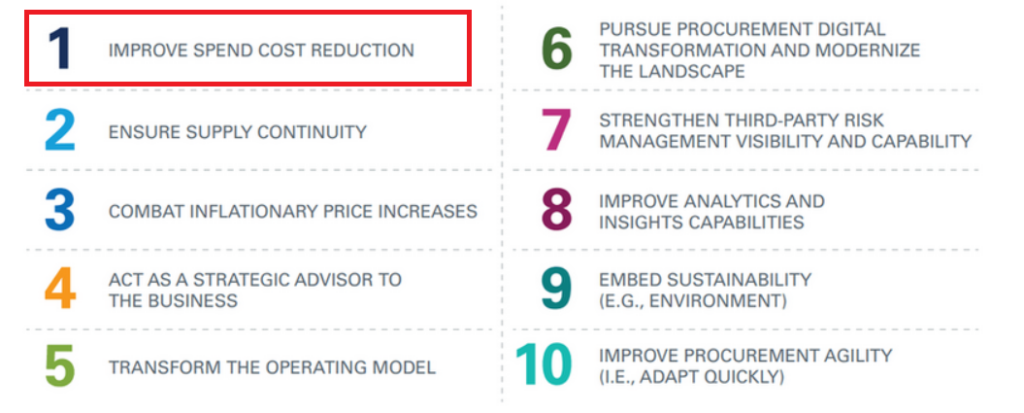

Balancing cost savings with quality presents a significant challenge in procurement.

Especially now that reducing costs is again the number one priority for procurement leaders, according to The Hackett Group’s 2024 Key Issues research.

Source: The Hackett Group

While reducing costs is a priority in response to all the global economic challenges, it shouldn’t be done at the expense of quality.

After all, sacrificing quality can lead to various negative consequences, including:

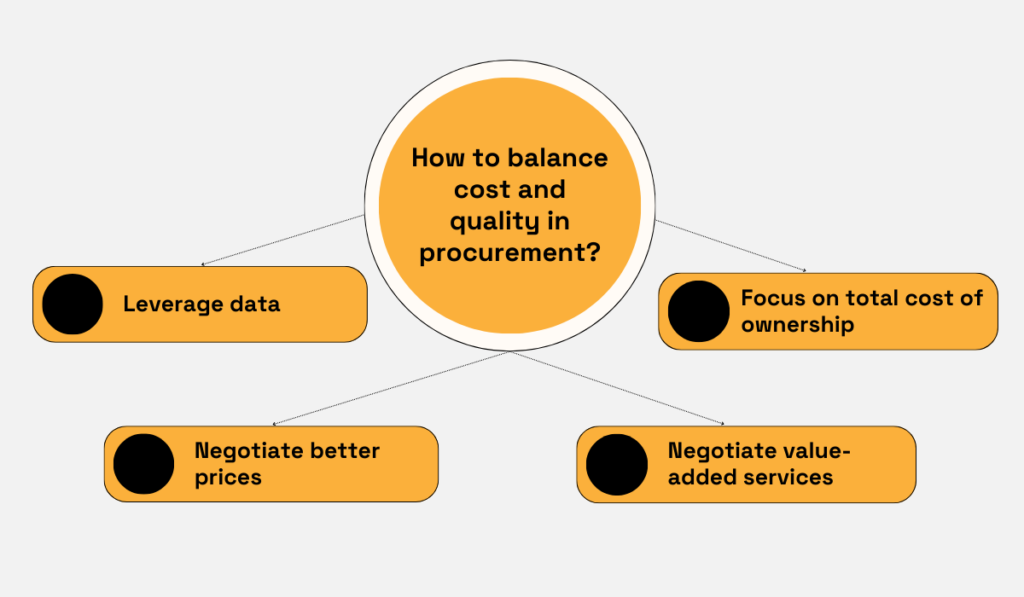

So, how can you balance cost and quality in your procurement?

One highly effective strategy lies in leveraging data-driven decision-making.

Strategic procurement heavily relies on analyzing supplier performance data to pinpoint opportunities for cost reduction while upholding quality standards.

So, when you diligently track supplier performance and leverage that data, you can identify opportunities to reduce costs without compromising on quality.

For instance, identifying reliable suppliers that offer high-quality products allows you to negotiate better prices, whether through bulk purchasing or contract extensions.

Another approach to better balance cost and quality is to focus on the total cost of ownership (TCO).

This means considering not only the initial purchase price but also the costs associated with owning and maintaining the product over its lifecycle.

For example, outsourcing logistics or other processes may optimize the overall cost of ownership, allowing you to invest in higher-quality products while reducing costs related to warehousing, transportation, and inventory management over time.

Another way to balance cost and quality is through cost avoidance, especially by negotiating value-added services.

These services may include warranties, free maintenance, or other value-added offerings that would enhance product quality while avoiding additional costs in the long run.

Source: Veridion

The key takeaway is to avoid solely pursuing the lowest price, as this often leads to compromises in quality that can harm your reputation and, ultimately, your financial health.

Instead, strategic sourcing, supplier evaluation, negotiation, and a focus on optimizing the total cost of ownership enable you to overcome this challenge effectively.

By prioritizing quality and leveraging data-driven insights, you can balance cost savings and quality assurance in procurement processes.

Adopting new technologies like AI, data analytics, and automation can significantly boost procurement efficiency and decision-making, leading to improved outcomes and cost savings.

However, this journey is not without its challenges.

From stakeholders being hesitant to change to compatibility issues between current systems and new technologies, organizations face various obstacles.

Resistance from employees to technology adoption is a major roadblock for one-fourth of businesses, as per Userlane’s 2023 State of Digital Adoption report.

Illustration: Veridion / Data: Userlane

After all, tools can’t deliver benefits if people don’t want or know how to use them.

This resistance can stem from fear of job displacement, skepticism about new technologies, or simply a reluctance to change routines, as we already explained earlier.

But employees aren’t the only challenge.

Integration between new technologies and your existing systems can also be complex and challenging.

Incompatibility issues may arise during the implementation phase, resulting from differences in technology standards, data formats, or communication protocols between the new and existing systems.

Additionally, challenges may emerge when the new technology lacks interoperability with legacy systems or when there are complexities in data migration processes.

These compatibility challenges can lead to:

On top of all that, inadequate user training and support can hinder the effective adoption and utilization of new technologies, further compounding the challenges.

However, with careful planning and change management, you can overcome these challenges, too.

The key is to develop a comprehensive technology integration plan, which should include:

While technology adoption in strategic procurement presents many challenges, prioritizing user training, change management, and ongoing support can help you overcome them.

By doing so, you can harness the full potential of new technologies to drive efficiency and innovation in your procurement processes, achieve cost savings, and enhance your procurement performance overall.

As we confirmed throughout this article, strategic procurement does come with its fair share of challenges.

From navigating resistance to change and ensuring compatibility between existing systems and new technologies to addressing the complexities of supplier relationship management and the lack of visibility into suppliers’ operations, the journey towards strategic procurement is undoubtedly multifaceted.

However, acknowledging and addressing these obstacles head-on will help you on this path.

Remember, the key lies in leveraging data-driven decision-making, prioritizing user training and change management, and ensuring seamless integration of new technologies.

Keep these strategies in mind, and let them guide you toward achieving your strategic procurement objectives.