Quick Guide to Supplier Evaluation

Evaluating suppliers is vital for any business relying on external partners to provide quality goods and services at competitive prices.

A robust evaluation process ensures your company works with reliable, cost-efficient, and compliant suppliers who align with your goals.

Neglecting supplier evaluation—whether for prospective or existing suppliers—can lead to poor quality, disruptions, financial loss, and reputational damage.

In this guide, we’ll explore why supplier evaluation matters, when and how to do it, and which tools can streamline this critical task.

Let’s get started.

Supplier evaluation is a cornerstone of effective procurement and smooth operations.

It ensures your organization works with partners who consistently deliver quality, reliability, and value.

Whether evaluating new suppliers or assessing the performance of existing ones, the goal remains the same: minimizing risks and maximizing benefits.

For new suppliers, evaluation is about assessing their suitability—examining their financial stability, compliance with standards, and ability to meet your needs.

As for existing suppliers, it’s about ensuring continued alignment with your expectations, such as maintaining quality, competitive pricing, and timely deliveries.

Here are the top benefits of supplier evaluation for both new and existing suppliers.

Source: Veridion

While these benefits often overlap, their focus shifts depending on whether you’re assessing a new supplier or monitoring an existing one.

For instance, evaluating new suppliers helps you identify risks like inadequate production capacity, financial instability, or non-compliance with regulations.

This allows you to make an informed decision about whether they can reliably meet your requirements before formalizing the partnership.

Conversely, monitoring existing suppliers helps detect emerging risks, such as their declining financial health or deviations from agreed-upon sustainability standards.

This enables you to address such issues proactively.

Here’s how the remaining four benefits of supplier evaluation apply to both prospective and current suppliers:

| Benefit | New suppliers | Existing suppliers |

|---|---|---|

| Encourages Better Supplier Performance | By assessing past performance and compliance | By conducting regular performance reviews to maintain or improve standards |

| Enhances Quality Assurance | By verifying quality standards and certifications | By implementing ongoing quality checks to detect issues early |

| Eliminates Unnecessary Costs | By comparing prices and terms to secure the best deal | By identifying cost-saving opportunities and eliminating inefficiencies |

| Allows You to Review Your Business Needs | By evaluating alignment with business needs (e.g., sustainability, innovation) | By reassessing supplier capabilities as your business evolves and goals shift |

Along with these benefits, supplier evaluation plays a critical role in navigating the complexities of global supply chains.

In today’s interconnected economy, supply chains present both new opportunities and significant challenges.

But evaluating suppliers thoroughly allows companies to anticipate and mitigate many such risks before they impact operations.

To illustrate the current landscape, here’s what experts at Everstream Analytics identified as the top five supply chain risks in 2024.

Illustration: Veridion / Data: Everstream Analytics

Supplier evaluation is one of the key tools in mitigating these risks, ensuring your supply chain remains resilient in the face of uncertainty.

For example, assessing a supplier’s production capacity and access to raw materials ensures they can meet demand even during commodity shortages.

A robust evaluation process also helps identify alternative suppliers that can step in during disruptions caused by unforeseen external factors.

Similarly, evaluating a supplier’s geographic location and exposure to political risks allows businesses to diversify their supplier base, reducing reliance on high-risk regions.

As Thomas Sander, an expert in sustainable logistics, explains:

Illustration: Veridion / Quote: Medium

This quote—along with everything else we discussed so far—underscores that supplier evaluation is far more than a box-ticking exercise.

It’s a strategic process that safeguards your supply chain, enhances supplier performance, and positions your business for long-term success.

By assessing both new and existing suppliers, you can mitigate risks, seize opportunities for cost savings and innovation, and build a more resilient and sustainable supply chain.

Now that we’ve established why supplier evaluation is essential, let’s delve into when it should take place.

Clearly, evaluating suppliers is not a one-and-done activity.

Instead, it’s a continuous process that demands thoughtful timing.

Depending on your industry, procurement strategy, and supplier relationships, the frequency and triggers for evaluations may vary significantly.

Expectedly, evaluations of potential new suppliers are conducted during the initial selection process, ensuring they meet your selection criteria.

This process helps you mitigate supplier risks and secure favorable terms from the outset.

For existing suppliers, however, evaluations are driven by a combination of routine reviews and specific events.

Routine evaluations ensure your suppliers are upholding performance standards while allowing you to identify cost-saving opportunities.

Event-driven evaluations, on the other hand, are initiated by changes such as:

The frequency of evaluations also depends on industry norms and contract specifics.

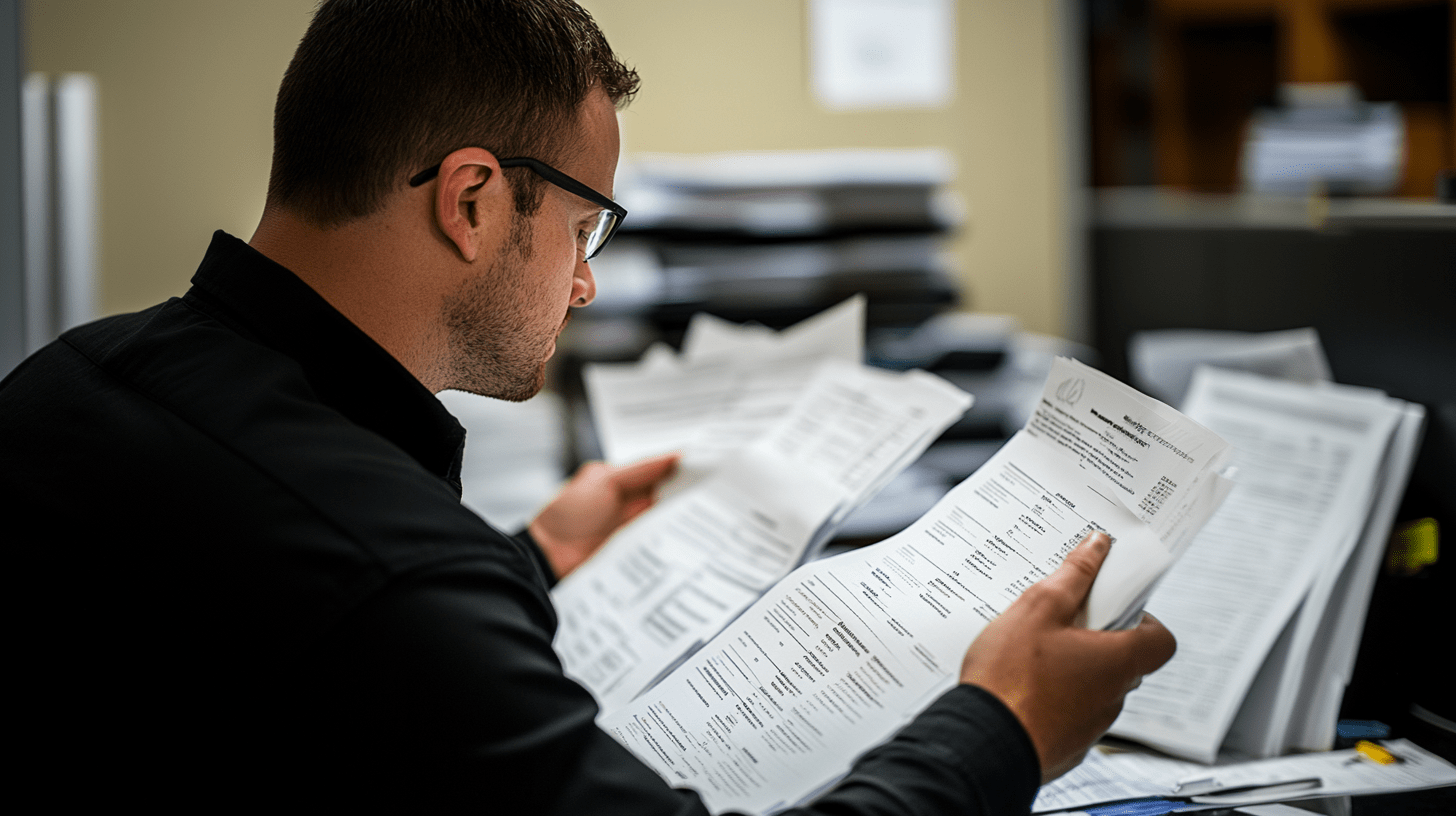

This Quora comment underscores that point:

Source: Quora

In this example, contract renegotiations—and, by extension, supplier re-evaluations—are scheduled annually.

Additionally, suppliers with significant contract values undergo comprehensive reviews every three years.

Of course, companies in this or other industries may opt for more frequent evaluations, such as biannual or even quarterly reviews, depending on their needs.

A key factor influencing the timing of supplier evaluations is the supplier’s criticality to your operations.

Suppliers who provide essential materials, components, or products—and are difficult to replace—often require more frequent and thorough assessments.

In any case, regular evaluations help ensure that supplier capabilities remain aligned with your company’s evolving goals.

They also enable you to address potential issues proactively, safeguarding your supply chain’s stability and overall efficiency.

The process of evaluating both prospective and current suppliers can range from relatively straightforward to highly detailed, depending on your procurement needs and goals.

At its core, supplier evaluation is a structured process designed to assess whether a supplier can meet—or continue to meet—your business requirements.

This approach goes beyond a surface-level review, relying on systematic tools like matrices and scorecards to ensure consistency and objectivity.

Such tools enable companies to rank and compare suppliers, evaluate their performance, and uncover risks or opportunities for improvement.

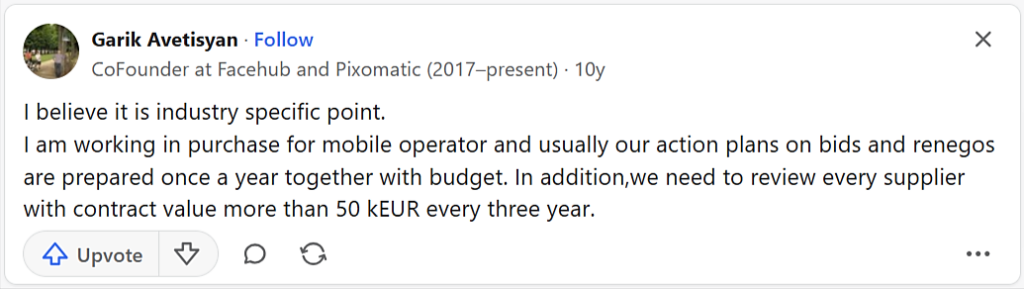

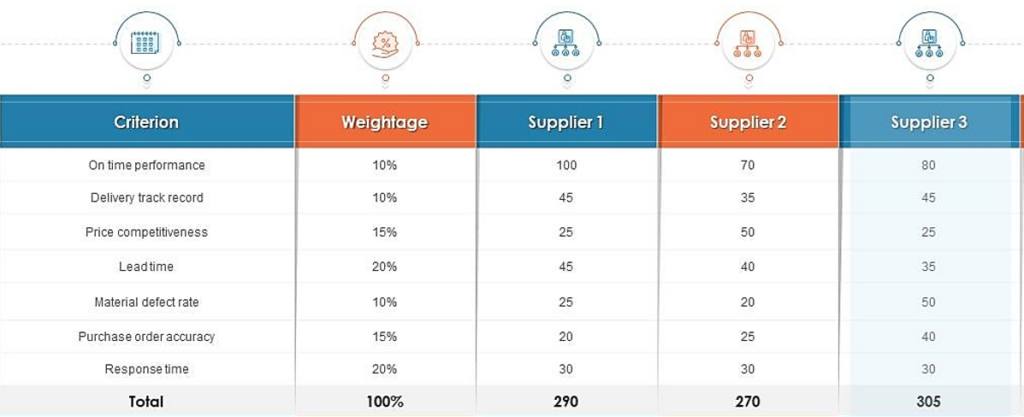

For instance, supplier scorecards provide a framework for scoring suppliers against critical evaluation criteria, often aligned with supplier key performance indicators (KPIs).

Here’s an example of a typical scorecard template.

Source: Tipalti

As shown, the critical supplier evaluation metrics almost always include quality, delivery, and cost (QDC).

These foundational elements are central to most supplier evaluation models, ensuring that suppliers meet essential performance expectations.

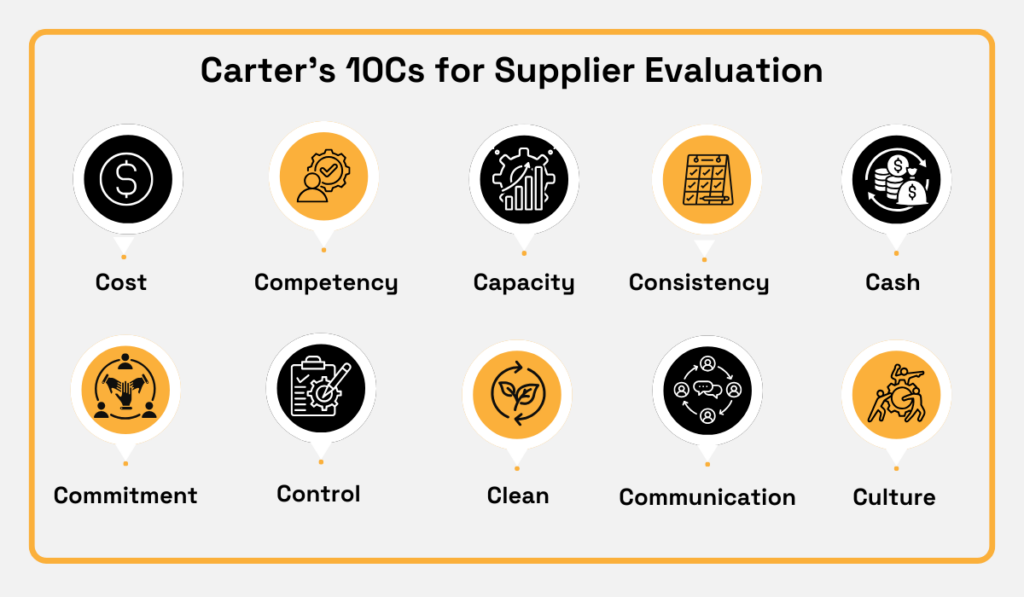

Beyond these basics, another popular supplier evaluation framework is Carter’s 10Cs.

This model adds several important dimensions to the evaluation process, offering a broader perspective on a supplier’s suitability for your business.

Some of these Cs include:

You can see all 10Cs in the illustration below.

Source: Veridion

Once your procurement objectives are set and evaluation criteria defined, the next step is to collect supplier data.

For potential new suppliers, this can be done through various effective methods such as supplier surveys, data collection from external sources, onsite visits, and reference checks.

As for existing suppliers, data collection methods expand to include internal sources like performance reports, as well as onsite audits to assess ongoing performance.

After collecting the necessary information, suppliers are scored based on how well they meet the predefined criteria.

Scoring systems typically incorporate both quantitative metrics, such as lead times or defect rates, and qualitative factors, like communication quality or responsiveness.

Once scoring is complete, the results are analyzed to summarize performance and compare suppliers objectively.

Source: Slide Team

Finally, this analysis forms the basis for decision-making.

When evaluating prospective suppliers, the goal is to select the best fit for your company while keeping other shortlisted candidates as potential backups.

In the case of your current suppliers, decisions often focus on addressing performance gaps, renegotiating terms, or exploring alternative options when necessary.

By following these steps, your team can ensure a structured and objective approach to supplier evaluation.

Whether selecting new partners or optimizing existing relationships, the evaluation process helps reduce risks and make informed decisions on supplier selection and performance management.

With the evaluation process outlined, let’s explore which tools—besides matrices and scorecards—can streamline your supplier evaluations.

Nowadays, procurement automation tools and supplier data platforms have become essential for efficient and effective supplier evaluation.

These technologies are designed to collect, store, and analyze vast amounts of data, equipping your procurement team with actionable insights to make well-informed decisions faster.

They’re invaluable for evaluating both new and existing suppliers, offering tailored features to tackle the distinct challenges of each process.

So, let’s explore how tools can help you discover and evaluate potential new suppliers.

In today’s globalized and interconnected world, identifying prospective suppliers and assessing them can be a complex and time-consuming endeavor.

However, with the right tools, this daunting task can be streamlined, reducing the time required for supplier discovery and evaluation by over 90%.

A powerful example is our own Veridion, a supplier data, market intelligence, and risk management platform.

Source: Veridion

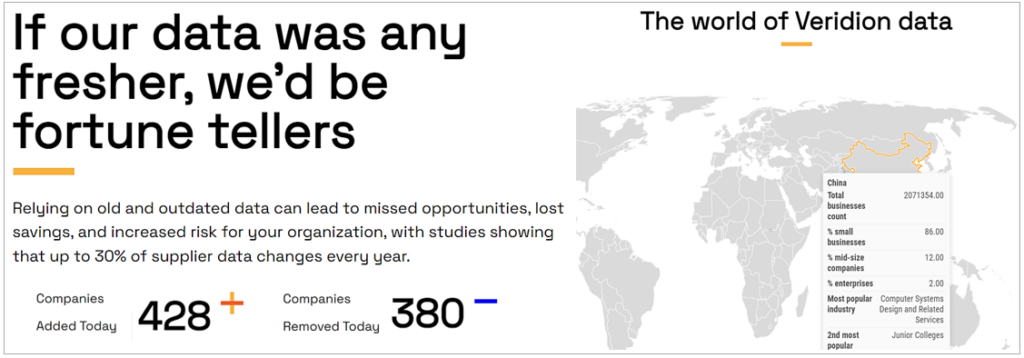

Veridion’s advanced AI-powered algorithms continuously scour the web, including public registries, news sites, and social media, to gather the most up-to-date supplier data.

Currently, this extensive database encompasses over 120 million companies across 200 million locations in more than 240 countries.

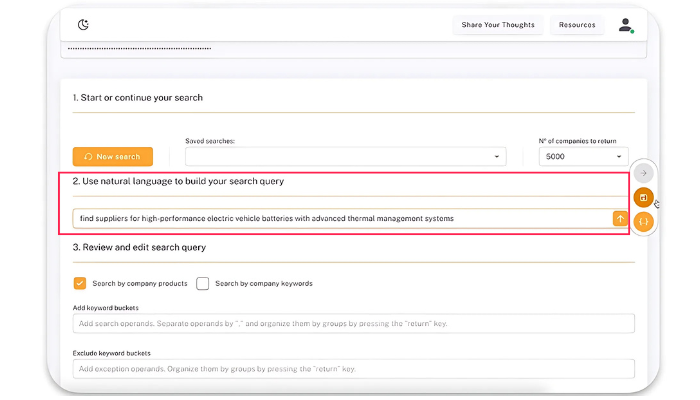

Through Veridion’s supplier discovery portal or its search API—easily integrated with your existing business systems—you can use natural language to input your search criteria.

Source: Veridion on YouTube

Once you’ve entered your criteria, simply hit “search” to generate a list of suitable suppliers in just a few seconds.

From there, you can refine the results by adding additional evaluation parameters, such as:

This last point has become increasingly critical, enabling you to assess suppliers based on their environmental impact, ethical practices, and commitment to fair labor standards.

Source: Veridion

Another key aspect of supplier evaluation is leveraging market intelligence.

With Veridion, you can benchmark potential suppliers against comparable companies in the market, empowering your team to make better-informed sourcing decisions.

Additionally, you can use Veridion’s data to assess potential risks facing suppliers, such as financial instability, local/regional political and economic risks, or ESG issues.

Source: Veridion

In addition to assessing risks for new suppliers, Veridion enables you to continuously monitor risks associated with your current suppliers.

You can set custom risk parameters, and if any issues arise, you’ll receive real-time alerts—allowing you to address potential problems proactively.

For performance monitoring, Veridion also helps fill gaps in your existing supplier profiles by providing the freshest data.

Source: Veridion

Of course, evaluating current suppliers also relies on data from internal sources.

This is where other procurement tools, such as procure-to-pay (P2P) systems, supplier relationship management (SRM) platforms, and contract management software, come into play.

These tools provide valuable insights into your suppliers’ transactional histories, compliance with contract terms, and overall performance trends.

By integrating data from multiple sources, you ensure that your supplier management decisions are supported by both external intelligence and internal performance metrics.

Together, all these tools form a comprehensive framework for supplier evaluation, equipping your team to make data-driven and strategic decisions with confidence.

We hope this guide was successful in highlighting the critical importance of supplier evaluation in modern procurement.

Whether selecting new suppliers or reassessing existing ones, this process allows your organization to optimize costs, mitigate risks, and build strong relationships.

Though it may seem complex, supplier evaluation can be streamlined with the use of appropriate methods and advanced tools.

The end result is a more resilient supply chain, improved supplier performance, and long-term value creation for your business.