8 Supplier Selection Criteria to Keep in Mind

Key Takeaways:

Think about the last time you bought something important—maybe a home appliance or a piece of tech.

You likely considered the price, the quality, and how quickly it would arrive.

We all do this in everyday life.

But when you’re managing procurement for a company, the stakes are much higher.

The right supplier can make or break your success.

That’s why today, we’ll explore eight key criteria that can guide you in selecting the right suppliers for your company’s needs.

Let’s dive in.

Price is probably the first thing that comes to mind when selecting a supplier—and that’s only logical.

You have a budget to manage, and your job is to ensure the company gets the best deal possible.

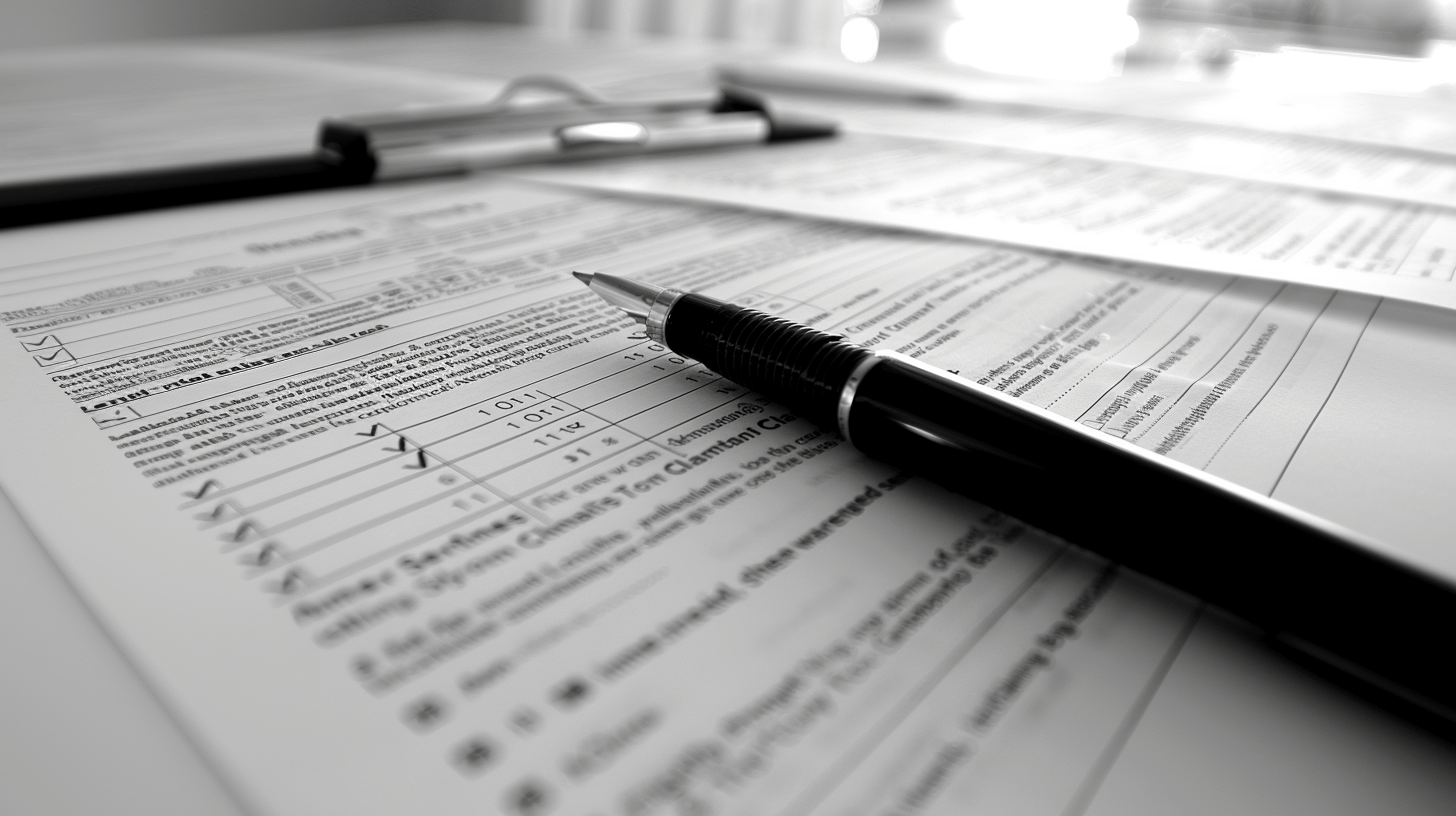

But here’s the thing many people forget—price isn’t just the number you see on the invoice.

Rather, it’s about the total cost of ownership over time.

Source: Veridion

Let’s say you find a supplier with an unbeatable product price, but you don’t consider the long-term costs.

Maybe the product needs constant repairs, or the warranty is too short, leading to replacements sooner than you expected.

Suddenly, that “great deal” isn’t so great anymore.

It’s like buying the cheapest washing machine, only for it to break down within a year.

Sure, the price tag was low, but what about the cost of repairs and frustration?

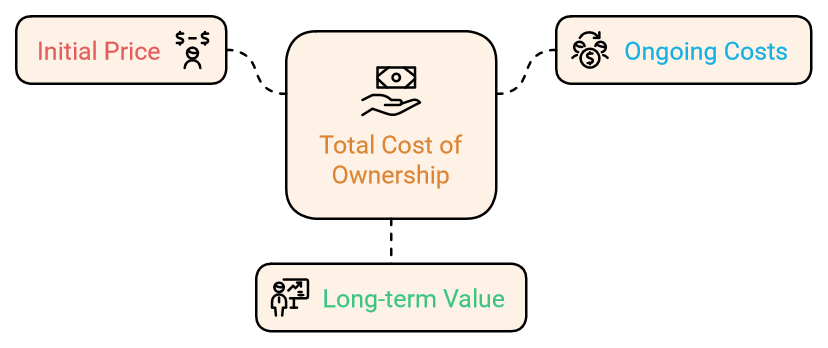

Here’s another angle to this criteria: suppliers often feel the pressure of price competition.

A recent Voice of the Supplier survey found that more than half of suppliers believe their customers prioritize price above all else, often overlooking the value they could get in the long term.

Illustration: Veridion / Data: HICX

Suppliers who feel valued are more likely to offer better service, flexibility, and sometimes even discounts as part of a long-term relationship.

So yes, price matters—but don’t let it overshadow everything else.

Consider the total cost of ownership and the supplier’s benefit, and you’ll secure a deal that works for the long haul.

No matter how tempting the price, if the product doesn’t meet quality standards, it’s not worth the cost.

Poor quality can cause higher returns, delays in production, or, worse, safety risks.

Here’s a case that proves the point.

Do you remember the Takata airbag scandal?

Defective airbags led to massive recalls, billions in losses, and, more tragically, injuries and deaths.

It’s a classic example of how bad product quality can damage a company financially but also tarnish its reputation.

Source: Reuters

To avoid this, it’s important to prioritize quality criteria and set clear quality specifications from the start.

Make sure your suppliers understand exactly what quality looks like for you.

The thing is, quality standards may vary depending on the supplier’s location due to varying regulations and industry practices.

Therefore, establishing a consistent quality benchmark for all suppliers—regardless of where they are based—ensures that products meet your expectations across the board.

Moreover, conduct audits, request product samples, and run trials to ensure that what you’re getting is up to standard.

In the end, only quality products will keep customers happy, protect your company, and ensure your operations run smoothly.

When it comes to suppliers, reliability is everything.

A reliable supplier delivers on time, every time, and according to the agreed specifications, helping you meet deadlines and keep your business running smoothly.

But what happens when a supplier isn’t reliable?

Disruptions in the supply chain can lead to missed deadlines, production slowdowns, or even halts.

And those are challenges no procurement professional wants to deal with.

So, how can you assess a supplier’s reliability?

Start by looking at their track record.

Check their on-time delivery rates, scrutinize their performance, and—perhaps most importantly—speak with their other clients.

That’s what David Hernandez, Co-Founder of Babonsono Imports LLC, suggests:

Illustration: Veridion / Quote: Linkedin

Hearing directly from someone who’s dealt with a supplier can give you insights you won’t find in a report.

In short, supplier reliability is essential for ensuring your supply chain remains strong and uninterrupted, so make sure to prioritize it when selecting suppliers.

Have you ever found the perfect product online, only to discover that the shipping costs are as high or even higher than the product itself?

It’s frustrating, right?

The same issue can arise in procurement if you don’t consider the supplier’s location.

Suppliers located closer to your operations can offer significantly lower shipping costs and faster lead times, resulting in a more efficient supply chain.

Moreover, working with nearby suppliers often makes communication easier and can help strengthen relationships through regular visits or in-person meetings.

However, choosing a supplier solely based on location can backfire.

If all your key suppliers are located in one region, what happens if a natural disaster or political instability strikes?

That’s what happened to major companies like Toyota, Sony, and Honda, in 2016.

When the earthquake in Japan happened, it disrupted their supply chains, forcing them to halt production because their suppliers were in the affected region.

Source: BBC News

That’s why it’s smart to diversify your supplier base.

Relying on a mix of local and international suppliers creates a safety net.

It ensures that if one region experiences disruptions, your business won’t come to a grinding halt because alternative suppliers can fill the gap.

So, when considering location as a criterion, think beyond proximity alone.

Consider how geographic diversity can protect your operations from unforeseen events while still ensuring cost efficiency.

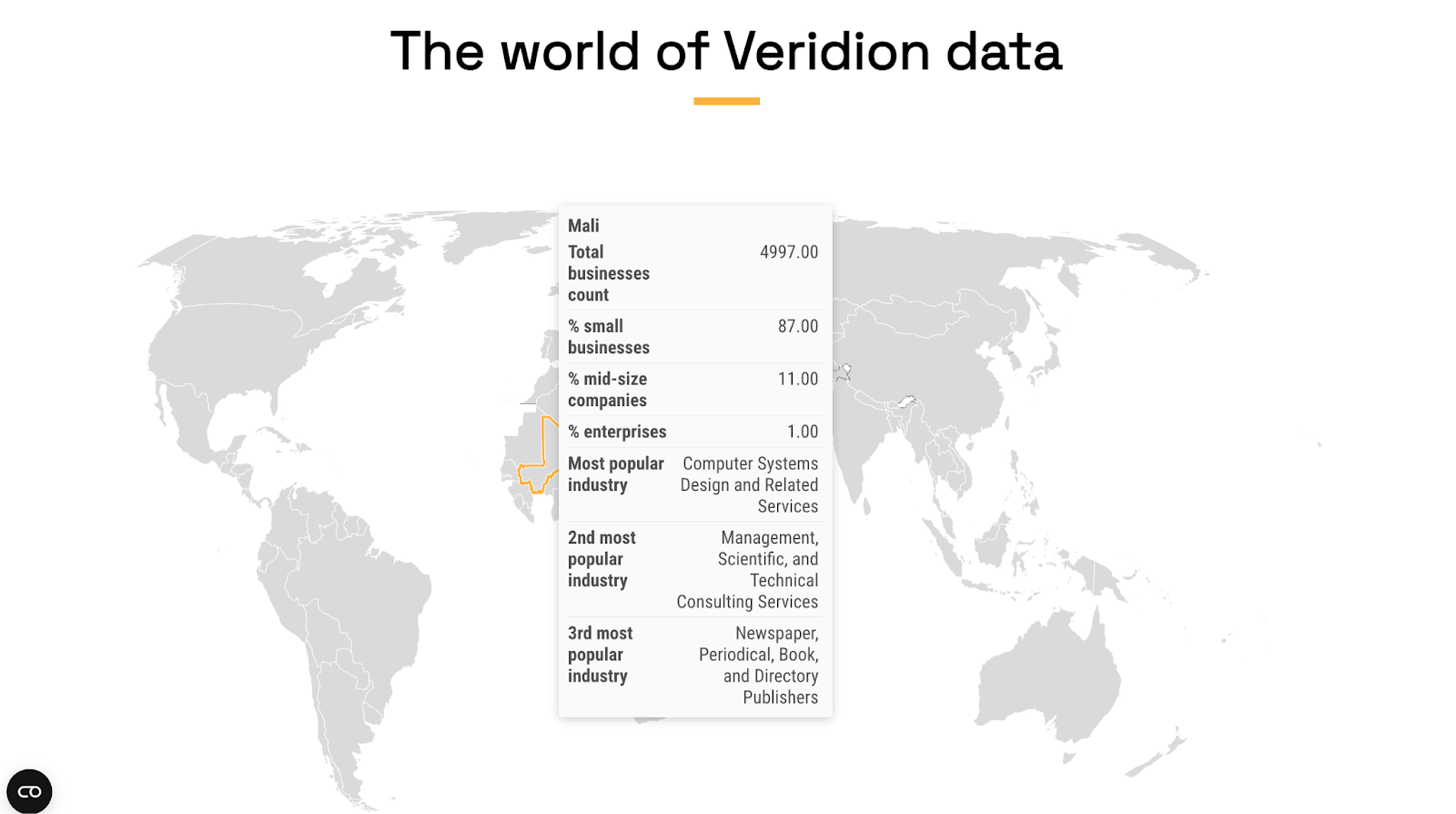

And if you’re wondering where to start finding suppliers outside your usual area, Veridion has you covered.

Our supplier discovery platform allows you to search for suppliers that match your criteria from almost any location in the world.

With data covering over 100 million companies in more than 240 countries and territories, you can easily find the right supplier no matter where they are.

Source: Veridion

All you need to do is input your criteria, and Veridion will provide a list of potential suppliers in minutes.

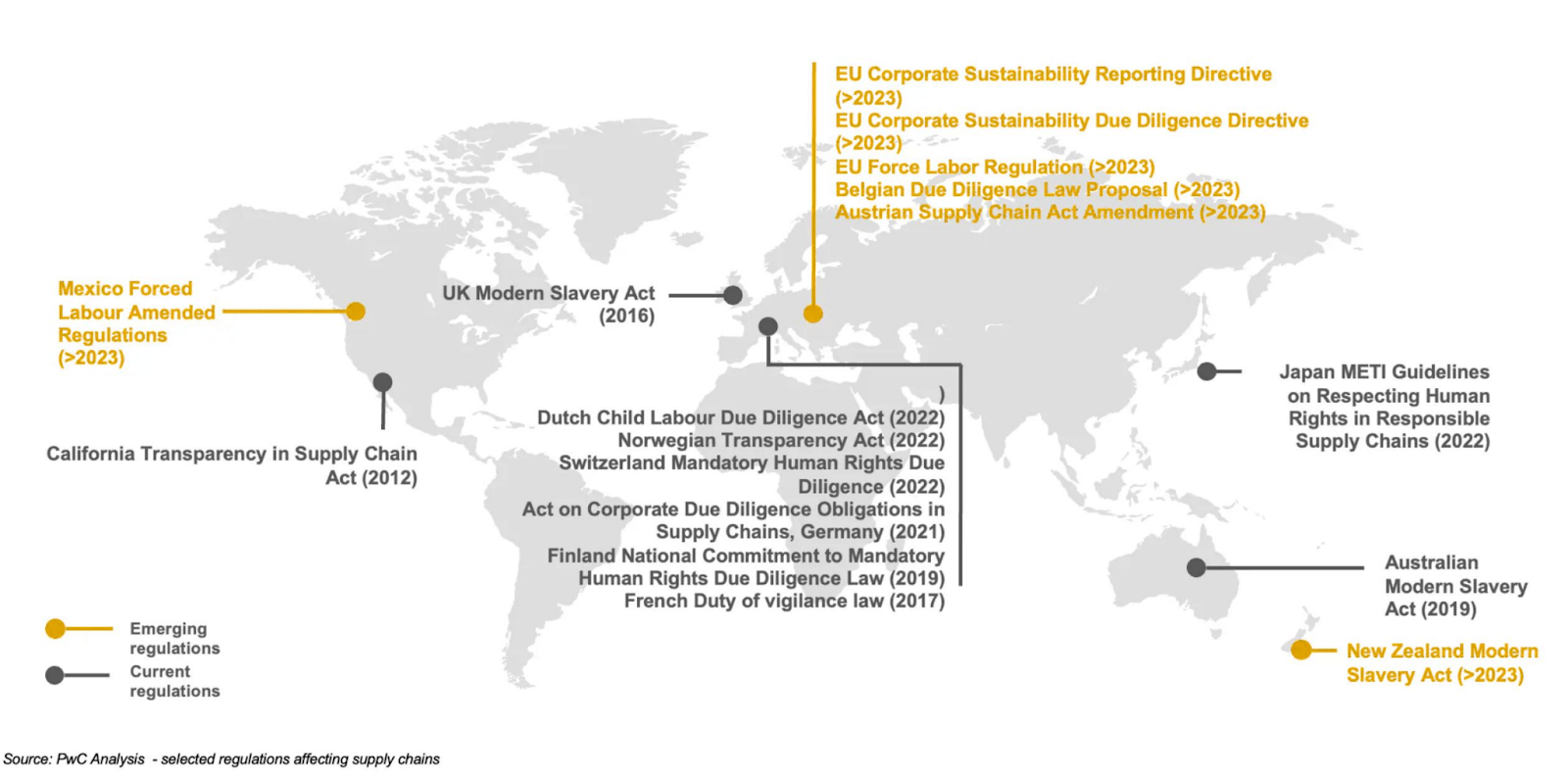

Suppliers must follow industry standards, environmental laws, labor practices, and safety regulations.

But the range of regulations can be overwhelming: they range from human rights laws like the Modern Slavery Act, and corporate due diligence obligations, to various environmental standards.

What’s more, each region has its own set of rules, making compliance a crucial factor when selecting suppliers.

Source: Veridion

No matter how big or small your company is, working with a supplier who doesn’t meet critical legal requirements can expose your business to serious legal and financial risks.

To avoid such issues, review your suppliers’ certifications, conduct regular audits, and request up-to-date documentation.

By prioritizing compliance from the outset, you’ll protect your company against legal issues and maintain an uninterrupted, efficient supply chain.

A financially stable supplier is less likely to experience disruptions that could affect deliveries or service quality.

Additionally, when a supplier is financially sound, they can invest in better technology and offer innovative solutions.

This gives you an edge by potentially accessing cutting-edge ideas before your competitors.

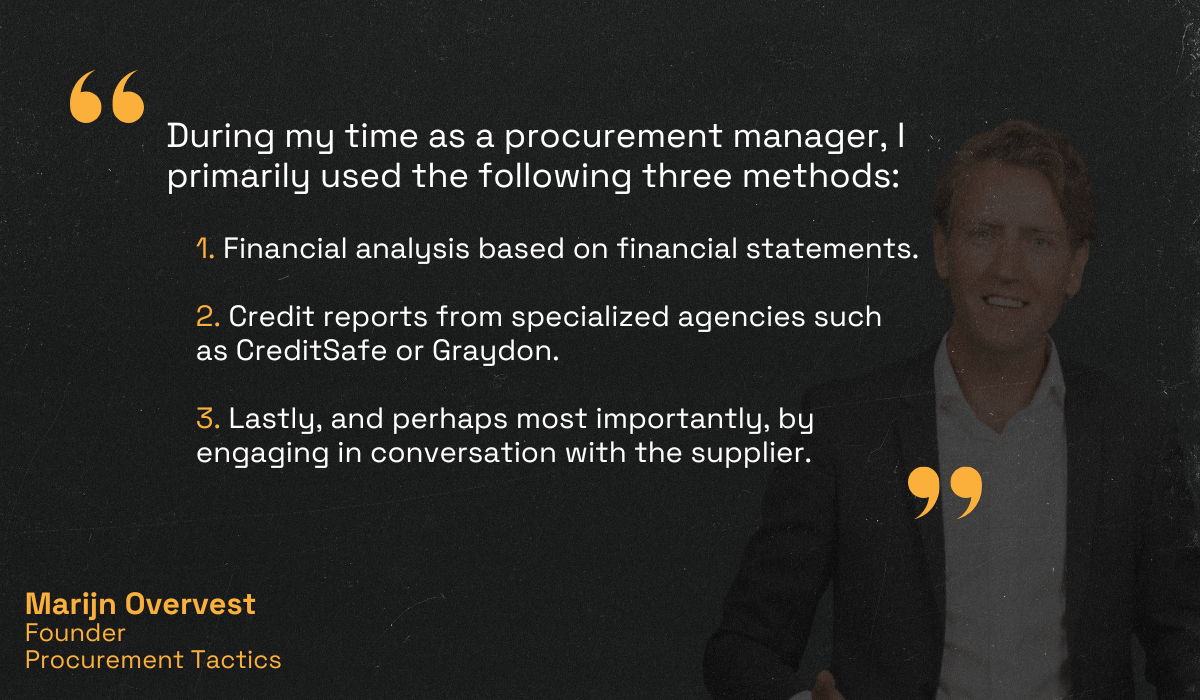

But how can you know if suppliers are financially stable?

Marijn Overvest, founder of Procurement Tactics and former procurement manager, explains which methods he used to evaluate a supplier’s financial stability:

Illustration: Veridion / Quote: Procurement Tactics

Why is this last point so crucial?

When you speak with suppliers, you get a feel for their long-term vision, their willingness to invest in innovation, and whether they’re upfront about any financial challenges they might face.

It’s this trust-building dialogue that can offer a more complete picture of the supplier’s financial health and future viability.

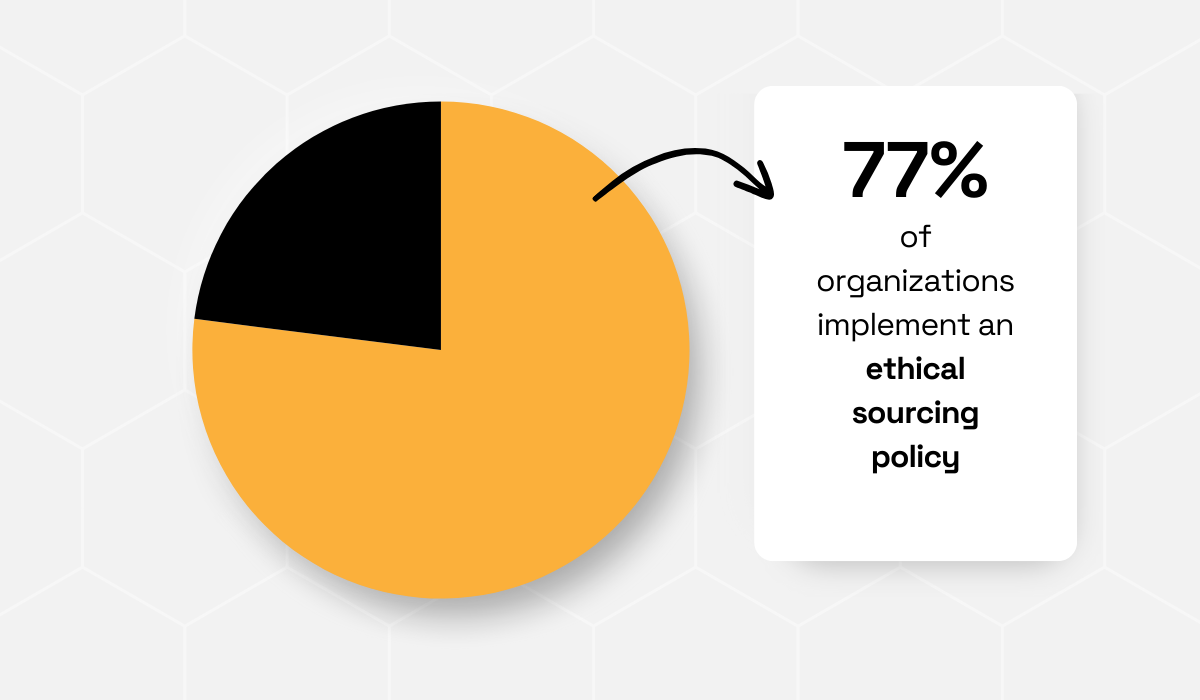

Social responsibility is no longer a secondary consideration—it’s becoming one of the core factors in supplier selection.

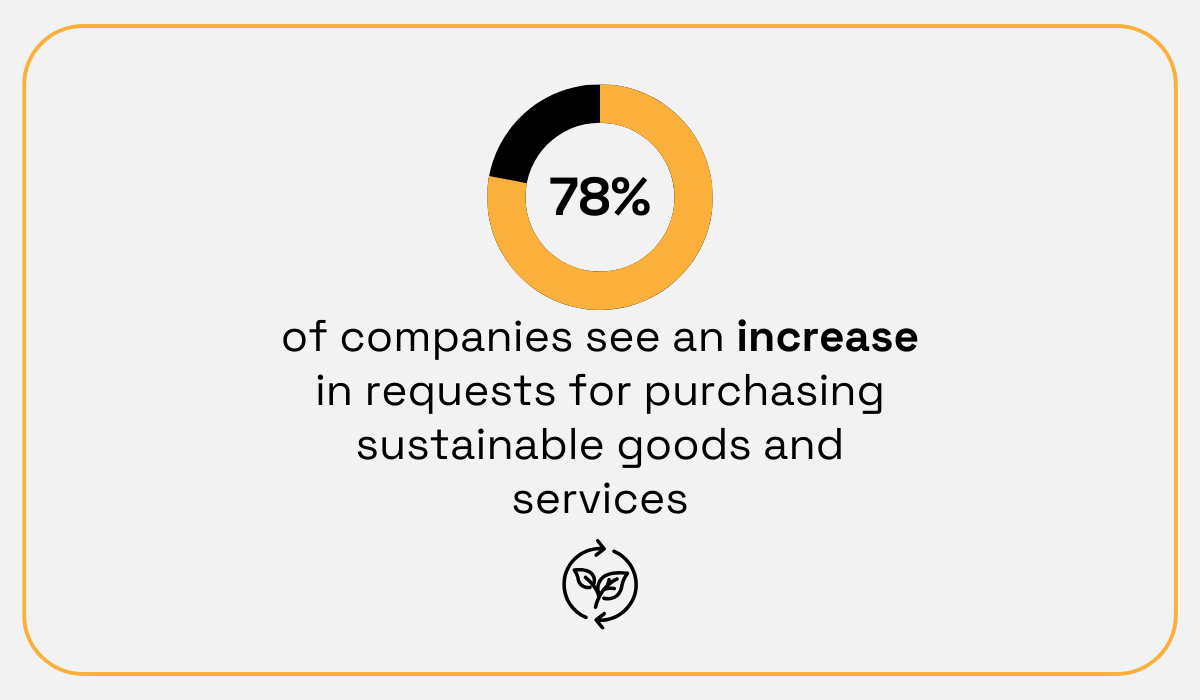

Recent data shows that 77% of organizations now have an ethical sourcing policy, and the demand for sustainable goods and services is also climbing.

Illustration: Veridion / Data: CIPS

In fact, 78% of businesses report a rise in requests for eco-friendly products, according to a Procurious and Ivalua survey.

Illustration: Veridion / Data: Procurious

All this indicates that both sustainability and ethics should be one of the main priorities for your business.

Consequently, you need suppliers who will align with those values.

On the other hand, we’ve seen large-scale consequences with companies whose suppliers fail to meet these expectations.

For example, in 2020, Boohoo, a fast-fashion retailer, faced a major scandal when it was revealed their suppliers underpaid workers, which caused significant reputational damage and led to a £1 billion drop in market value.

Source: The Guardian

To avoid such risks, procurement teams should review suppliers’ ESG policies, certifications, and sustainability reports.

Regular audits and assessments are key here.

On top of that, when searching for new suppliers, you can use tools that filter suppliers based on critical ESG factors such as atmospheric contamination, carbon footprint, illegal deforestation, water usage, and labor standards.

Only by having real-time data into these areas will you ensure you make informed decisions that support your social responsibility goals.

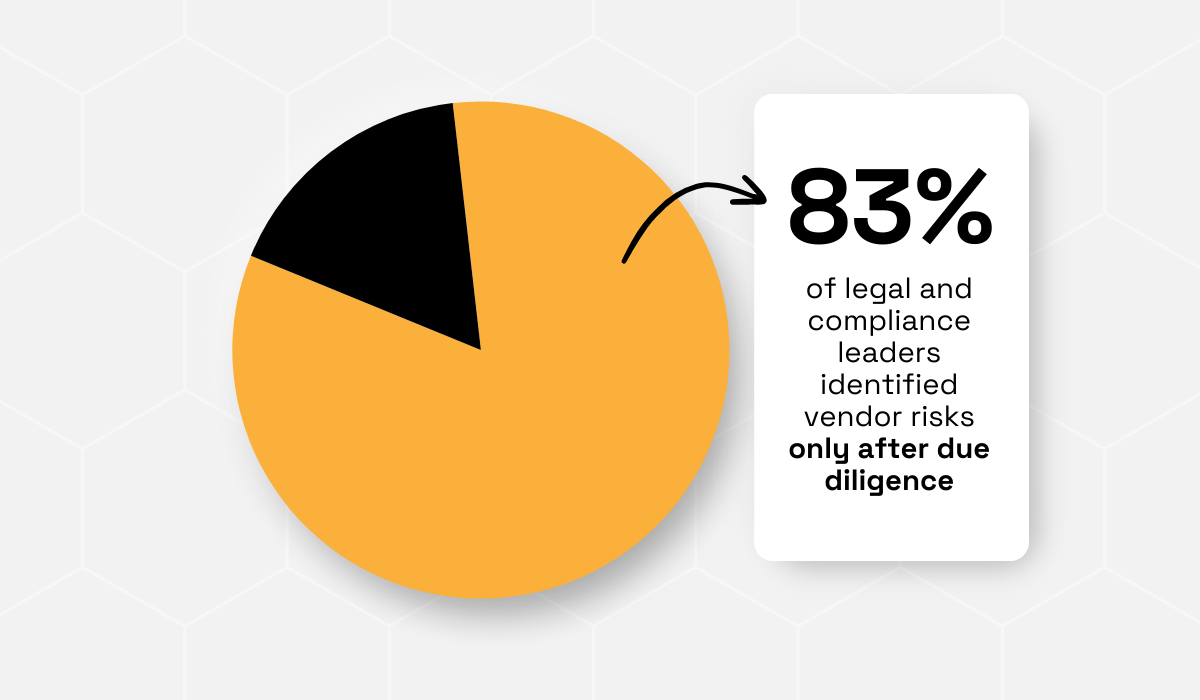

Every supplier comes with a certain level of risk.

Whether it’s geopolitical instability, natural disasters, or financial issues, these risks can disrupt your supply chain and your business.

But here’s the tricky part:

According to Gartner’s 2019 Third-Party Risk Management model, 83% of legal and compliance leaders say they only identified supplier risks after they had already started working with them.

Illustration: Veridion / Data: Gartner

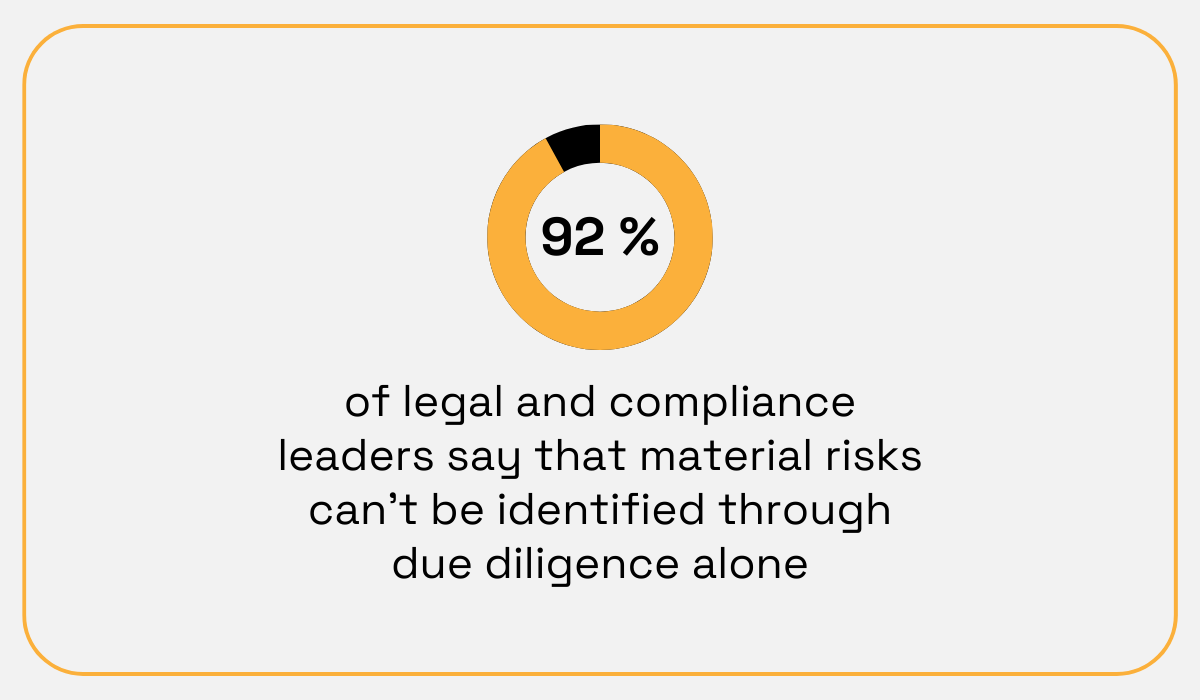

This brings us to an important point—due diligence is crucial, but it’s not foolproof.

In fact, 92% of leaders said that material risks couldn’t be identified through due diligence alone.

Illustration: Veridion / Data: Gartner

So, what does this mean for you?

First and foremost, conducting a thorough risk assessment before selecting suppliers is essential.

Assess factors like geopolitical stability, financial health, and compliance with regulations.

But remember, risk management doesn’t stop there.

The real key is to continuously monitor your suppliers’ risk potential throughout your relationship with them.

For example, imagine discovering that one of your key suppliers has lost a certification critical for maintaining regulatory compliance.

Without ongoing monitoring, this could lead to serious consequences for your company.

With our Veridion, you can stay informed even about such changes.

Veridion not only helps you find reliable suppliers but also keeps an eye on their activities, alerting you if anything shifts—whether it’s a sudden decline in financial stability or the loss of essential certifications.

Source: Veridion

This continuous monitoring helps you stay agile and proactive, reducing the risks associated with supplier relationships.

Choosing the right supplier depends on what matters most for each purchase.

Sometimes, price takes the lead; other times, location or product quality might be the priority.

However, as procurement gains more influence, other criteria like social responsibility and compliance are moving to the forefront.

These factors can’t be ignored because they help protect your brand, build trust, and ensure long-term success.

All in all, balancing all eight of these criteria in supplier selection will make your supply chain strong, adaptable, and ready to support your business in the long run.

So choose wisely.