6 Biggest Benefits of Strategic Procurement

Moving away from the transactional nature of traditional procurement, strategic sourcing is a systematic approach that allows procurement teams to focus on creating long-term value for their company.

By using advanced techniques and digital tools, it adopts a holistic perspective to promote lasting cost-efficiency, operational excellence, and risk mitigation.

To highlight its essential role in achieving success today, we will explore the six major benefits of strategic procurement, and support them with practical examples.

In procurement, both traditional and strategic, the primary goal beyond securing the desired product/service quality and delivery from your suppliers is, naturally, achieving the best possible price.

That’s logical since, for example, a 15% lower price translates into cost savings of the same magnitude.

Moreover, such savings are easiest to demonstrate to company management, which makes them a simple and compelling procurement performance metric.

However, as you know, cost savings go far beyond securing a favorable price, as recent supply chain disruptions have painfully shown.

And that’s where strategic procurement enters the stage as a vital cost-savings driver by ensuring supply chain resilience, operational continuity, and improved long-term procurement outcomes.

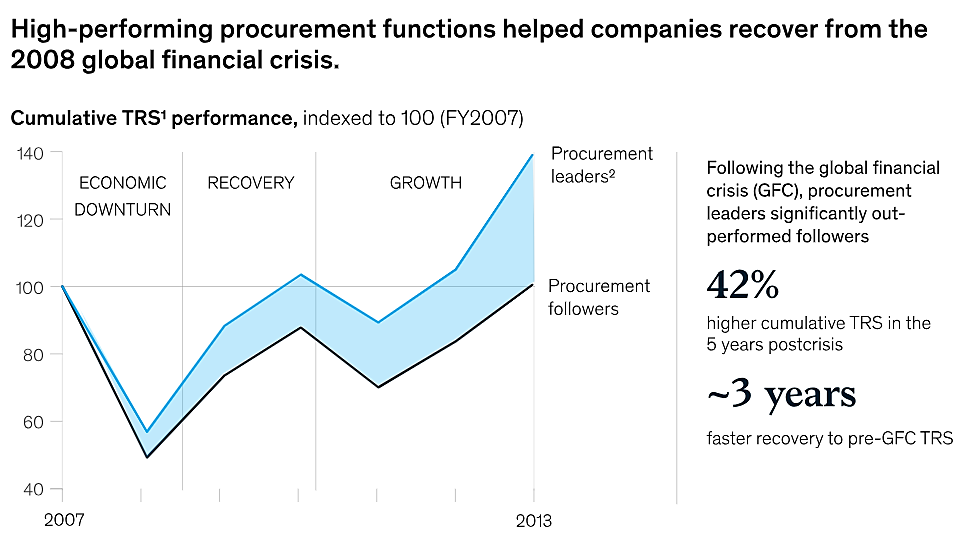

In fact, McKinsey’s research on business recovery following the 2008 global financial crisis revealed that companies with high-performing, strategically-inclined procurement functions outperformed their lower-performing peers by up to 42%.

Source: McKinsey

This demonstrates how strategic procurement helps companies rebound from a crisis and stay competitive by going beyond just finding the lowest price.

For instance, let’s say a company selects a slightly higher-priced supplier known for better product quality.

Despite the initial higher cost, this strategic decision enables the company to mitigate future expenses associated with returns, repairs, or replacements, ultimately enhancing customer satisfaction and overall operational efficiency.

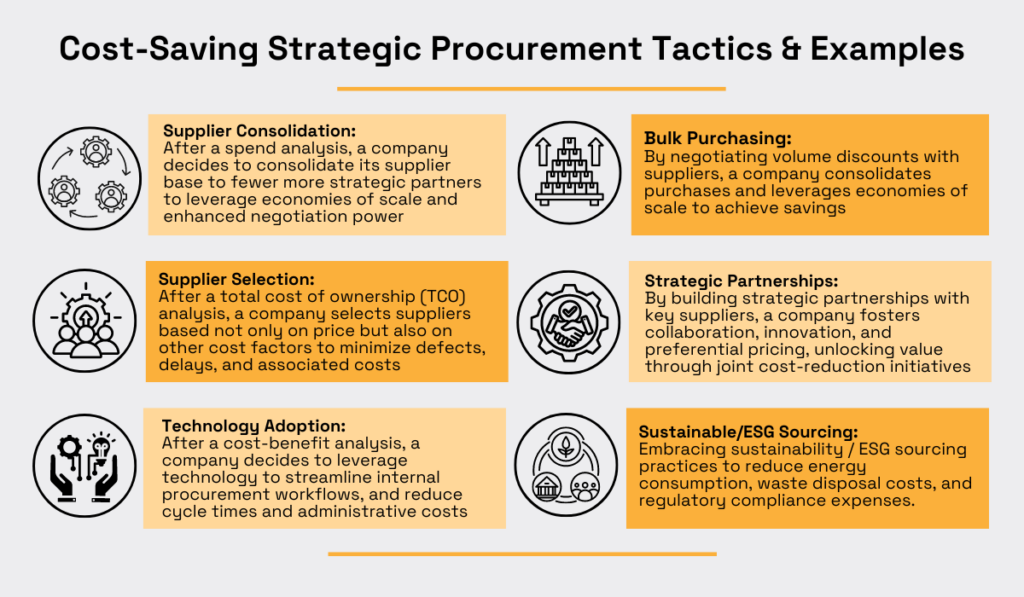

This illustrates just one of many savings-boosting strategic procurement tactics and examples, some of which are shown below.

Source: Veridion

These examples provide specific illustrations of cost-saving measures that companies can undertake based on different types of analyses and strategic approaches in procurement operations.

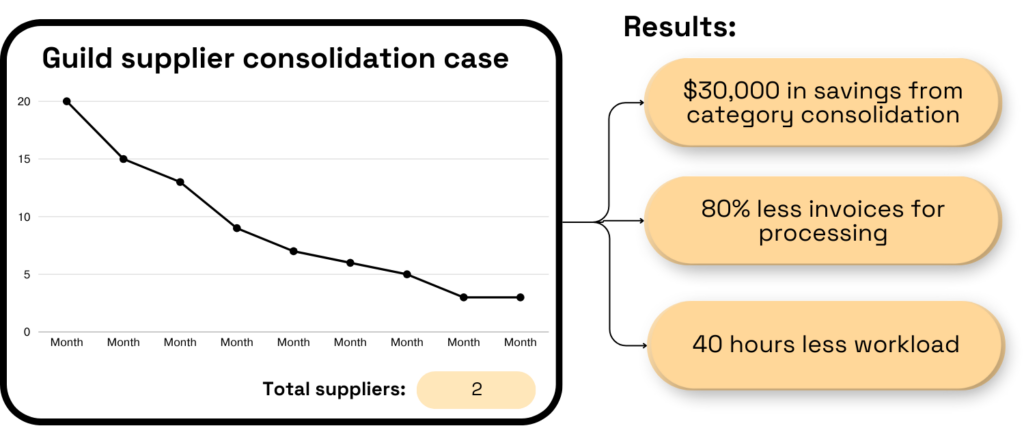

Now, it’s time for a real-world example of one strategic procurement method used to boost cost savings—supplier consolidation.

Back in 2017, Guild Mortgage Company was expanding rapidly, with the number of its locations growing from 70 to 160.

Since each Guild location was responsible for securing supplies for its own business needs, this expansion brought on financial and operational procurement inefficiencies.

This prompted the company management to look for ways to reduce procurement costs and increase efficiencies.

They decided to consolidate their supply spending, as discussed in a case study by Staples.

Ultimately, they reduced the number of their suppliers (for office supplies other than furniture and large IT equipment) from 20 to 1.

Illustration: Veridion

Since implementing this strategic cost-saving tactic, Guild has seen measurable benefits on a monthly basis, namely:

The monetary cost-savings were achieved by leveraging economies of scale and negotiating power of pooling office supplies under a single supplier.

It’s worth noting that this single-supplier tactic can backfire in some cases, when critical components disruptions occur.

But in this case, it worked!

The other two savings—reduced administrative work and a lighter workload—resulted in lower operational costs and increased productivity, further contributing to Guild’s overall savings and efficiency gains.

As said, strategic procurement goes beyond transactional interactions with suppliers; it fosters collaborative partnerships that cultivate trust, transparency, and mutual benefit.

These relationships are built on open communication, clear expectations, and shared objectives aimed at encouraging improvements and driving shared success for both parties.

The most well-known examples of strategic buyer/supplier collaboration include:

Here’s an example of joint product development between three companies, each supplying its own expertise in a collaborative effort to develop an advanced wireless electric vehicle charging kit.

Source: The EV Report

Regardless of how big or small your suppliers are, fostering stronger relationships and engaging suppliers as strategic partners (rather than mere transactional counterparts) can yield significant benefits for both sides, including:

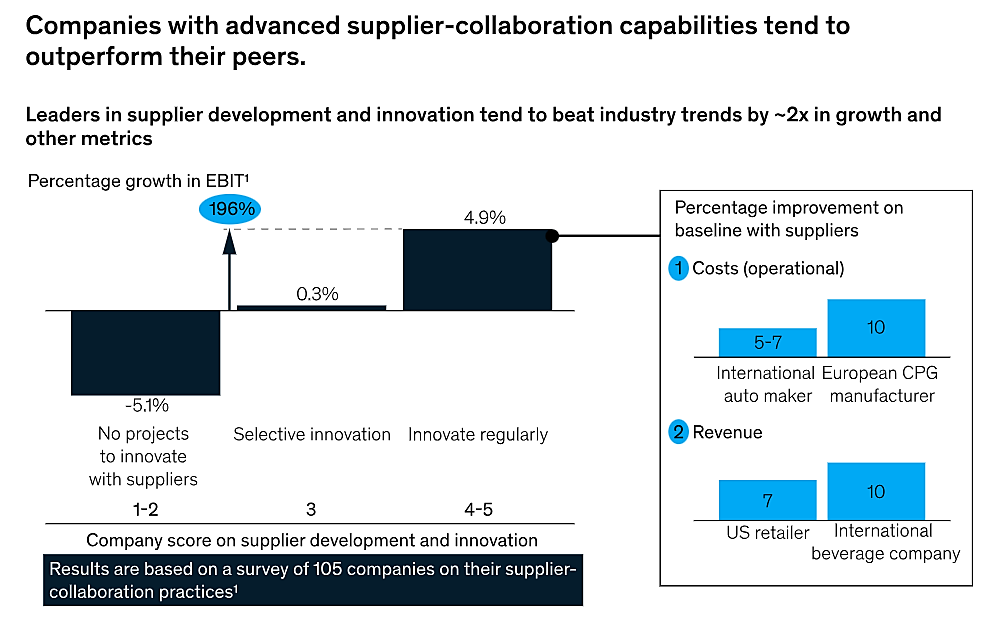

This short list of advantages is confirmed by a McKinsey survey of large corporations which showed that companies with regular supplier collaboration initiatives outperform their peers in terms of lower costs, greater profitability, and higher growth.

Source: McKinsey

Of course, one of the prerequisites for successful strategic relationship-building is establishing clear supplier performance metrics and feedback mechanisms.

By defining and regularly monitoring supplier KPIs, your procurement team can identify areas (quality, on-time delivery, lead time, etc.) where a supplier’s performance might be falling short.

Then, they can provide constructive feedback on how to address these shortcomings, building trust, increasing response times in case of disruptions, and opening opportunities for preferential procurement terms.

Likewise, the team can recognize areas where supplier-side improvements could unlock new sources of long-term value (i.e. cost savings or efficiency gains).

Through feedback mechanisms or supplier development programs, your company can provide guidance, resources, and support to help the supplier enhance their quality, production, and innovation capabilities.

This proactive approach incentivizes suppliers to continuously improve their offerings and service levels, fostering mutual growth and success in the partnership.

Collaborative relationships with suppliers are ingrained into the principles of strategic procurement, enabling companies to achieve long-term cost savings, enhance efficiency, and drive innovation.

Various strategic procurement efforts can shorten all kinds of procurement timelines, from initial supplier sourcing and evaluation to contract negotiation, order approval and processing, and supplier response time.

While there are numerous methods to reduce these timelines, leveraging technology, i.e., various data collection and analysis tools, stands out as one strategic measure that can produce the most significant results.

Let’s take the time needed to source new suppliers as an example.

This is typically the most time-consuming and resource-intensive task of procurement teams, involving identifying potential suppliers and evaluating them against a set of specific criteria and risk factors.

However, this process can be significantly expedited by utilizing various procurement software tools and big data platforms that facilitate supplier discovery, qualification, assessment, and selection.

This article’s title nicely illustrates the power of AI-driven software tools in cutting down supplier sourcing time.

Source: McKinsey

McKinsey’s experts estimate that the sourcing time can be reduced by 90 percent or more.

For instance, there are now proprietary machine-learning (ML) models used to continuously search the internet for relevant supplier data, allowing for the creation of a global, regularly updated database of company data.

This means that procurement teams can access vast amounts of supplier data and find prospective suppliers by specifying their search criteria, from precise product specifications to

their capacity, country/region, certifications, and sustainability/ESG practices.

One such global database with advanced search functions is our supplier-sourcing tool, Veridion.

Source: Veridion

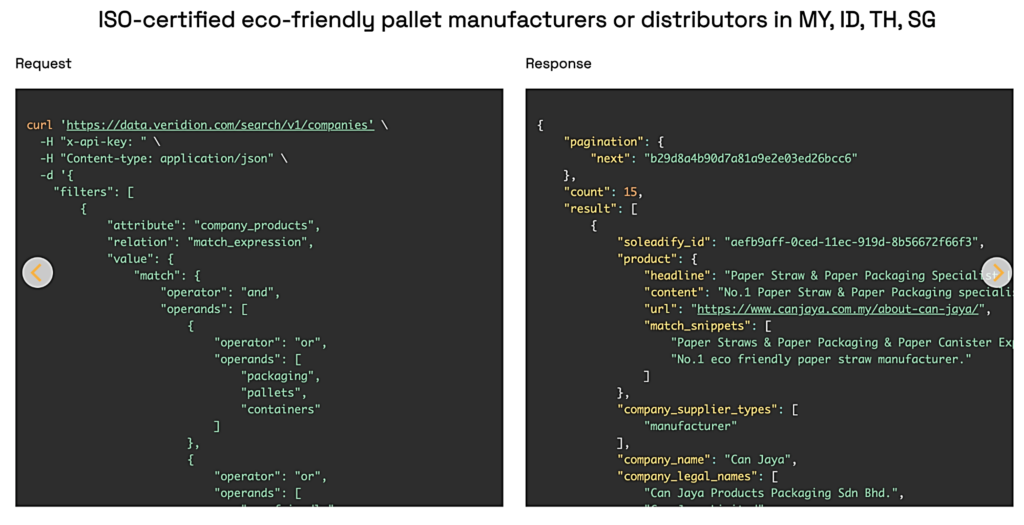

With the help of search APIs (that easily integrate with other procurement automation tools), your procurement team can use Veridion’s database to quickly find suppliers that fit specific procurement criteria.

Moreover, they can use natural language to input their search queries.

Source: Veridion

This means that the supplier discovery time is minimized to mere minutes, while also significantly reducing the time required for supplier evaluation and assessment.

Additionally, access to the latest market intelligence needed for efficient decision-making is readily available, reducing the time spent on market research and analysis.

Similarly, other procurement software tools can accelerate various procurement timelines.

For instance, implementing automated approval workflows can significantly reduce the time spent obtaining approvals for procurement activities.

By defining clear approval hierarchies and utilizing electronic approval systems, your company can expedite the approval process and avoid delays.

We should note that, other than technology adoption, there’s a range of other strategic procurement measures that contribute to faster procurement cycles, such as:

Overall, in strategic procurement, various tools and methodologies can be leveraged to shorten procurement timelines and enhance efficiency throughout the procurement process.

Managing supplier risk is a crucial aspect that contributes to overall supply chain resilience and operational continuity.

One of the primary ways how strategic procurement makes supplier risk mitigation easier is through robust supplier risk assessment and monitoring processes.

This involves evaluating suppliers based on various risk factors such as financial stability, regulatory compliance, geopolitical risks, and operational vulnerabilities.

Again, this is where risk management software, big data platforms, and supplier sourcing tools with their analytics and real-time alert capabilities are instrumental for success.

Source: Veridion

For example, if you use Veridion’s database, you can proactively mitigate supplier risk during initial supplier searches by setting custom risk factors and receiving relevant info together with data confidence/reliability scores.

This enables your team to identify high-risk suppliers at the outset, and either avoid those risks altogether (by not selecting them) or establish required risk mitigation strategies.

As for your current suppliers, you can receive real-time notifications of relevant changes in their operations, such as pending bankruptcy, tax or regulatory compliance problems.

That way, you can strategically mitigate potential issues before they escalate into significant disruptions.

Developing contingency plans for various risk scenarios and identifying alternative sources of supply is another aspect of a strategic approach to procurement.

In conclusion, strategic procurement enables companies to avoid or minimize various supplier-related risks by implementing appropriate risk management tools and practices, from real-time risk monitoring to supplier diversification and contingency planning.

Helping the company survive in a competitive market is the primary task of any function or department, including procurement.

Consequently, all the other benefits of strategic procurement outlined here directly or indirectly contribute to giving the company a competitive advantage.

For example, any cost-savings resulting from strategic procurement tactics can ultimately translate into lower prices/better terms for consumers, enabling the company to attract more customers and increase its market share.

That’s how Ikea outperformed its competitors back in the early days:

Source: MagnatesMedia on Youtube

Similarly, shorter procurement timelines, strong relationships with suppliers, and mitigated supply chain risks further reinforce the company’s competitive position by ensuring consistent product quality, availability, and reliability.

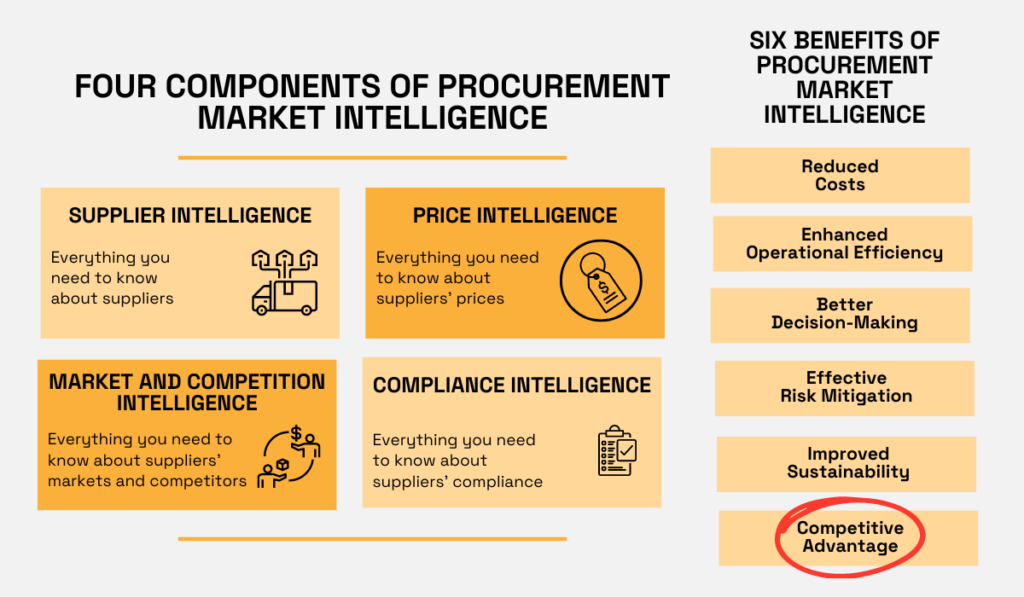

One notable strategic procurement method that can significantly strengthen competitiveness across multiple business aspects is market intelligence.

This involves using software tools to gather and analyze data on all components of the market to extract valuable insights and enjoy wide-ranging benefits.

Source: Veridion

Using market intelligence and data analytics tools, your team can analyze relevant data about market trends, competitor strategies, and supplier capabilities to inform the company’s decision-making and strategic positioning.

Long story short, market intelligence enables companies to:

This of course leads to data-driven decisions, allowing companies to adapt quickly to changing market dynamics and outperform their competitors.

Other strategic procurement measures, such as collaborative procurement for innovation and strategic partnerships, can also enhance a company’s competitiveness.

Ultimately, by embracing a range of strategic procurement tactics, companies can stay ahead of the competition, driving innovation and sustainable growth.

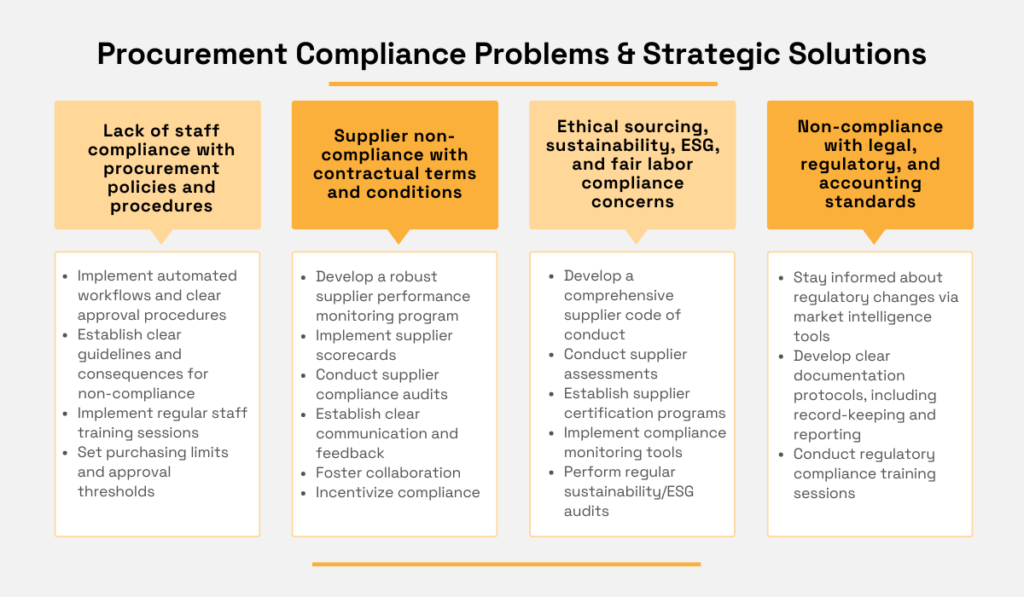

Various strategic procurement actions can be taken to improve another aspect crucial for organizational success—compliance.

Broadly speaking, compliance in procurement refers to:

In today’s business landscape, companies often face various compliance challenges in all these areas.

So, let’s explore some typical procurement compliance issues and appropriate strategic measures that can be applied to efficiently address them.

Source: Veridion

The suggested strategic procurement solutions aim to address some of the key compliance issues faced by companies, encompassing internal policies, supplier adherence, and regulatory requirements.

By implementing these and other strategic measures, organizations can improve their own and their suppliers’ compliance frameworks, as well as minimize legal liabilities, financial penalties, and reputational risks associated with non-compliance.

Therefore, strategic procurement enables teams to take proactive steps to concurrently enhance compliance and contribute to overall organizational resilience and success in the competitive marketplace.

As a combination of tech tools, data analyses, and prudently selected actions, strategic procurement offers numerous benefits, from increased cost savings to shorter timelines and an improved competitive edge.

It also empowers your team to reduce risks, build stronger relationships with suppliers, innovate more, and grow the business into a more resilient one.

We hope this article has shed some light on these benefits so that your company can get the most out of them and prosper too.