5 Best Practices for Improving Your Procurement Cycle

Are unreliable suppliers giving you headaches?

Is controlling costs a never-ending battle?

Are you struggling to meet procurement deadlines and align your activities with your company’s broader business goals?

If any of this sounds familiar, don’t worry—we’ve got you covered.

This article reveals five best practices to improve your procurement cycle.

That means more efficient processes, smoother workflows, better communication, improved risk mitigation, and so much more.

Intrigued?

Read on to find out more about how you can take your procurement to the next level.

A procurement strategy is a detailed plan that clearly specifies all the methods and processes to be followed to fulfill the company’s procurement needs in the most cost-effective and efficient manner.

As such, it’s a crucial component of a successful, disruption-free procurement cycle.

By standardizing procedures and defining everyone’s roles, a well-structured strategy reduces confusion, optimizes resource allocation, and cuts down on the time and effort required for each task.

More importantly, it also ensures all these activities are in line with the company’s broader goals.

For instance, if a business wants to improve its sustainability performance, it will first look to its procurement department to help achieve this goal.

However, procurement can’t really make any of that happen without a robust sustainability program that outlines clear criteria and policies for supplier selection, sourcing, waste reduction, and so on.

Take Puma’s “Forever Better” sourcing strategy as an example.

According to Anne-Laure Descours, their Chief Sourcing Officer, this initiative has been a real game-changer for the entire company.

Illustration: Veridion / Quote: Procurement Magazine

It enables them to procure more eco-friendly versions of leather, cotton, paper, and other materials, reducing their CO2 emissions for materials by almost a third.

It also supports Puma’s suppliers themselves in becoming more sustainable.

Namely, it empowers them to more than double their use of renewable energy by installing large-scale solar power systems at their facilities.

That’s right: these impressive results are entirely due to Puma’s procurement strategy.

It includes a strict supplier vetting process, collaboration with various stakeholders like NGOs, industry groups, as well as other brands, and regular sustainability performance tracking.

Of course, green procurement initiatives are only one example.

The truth is, a well-designed plan of action can bring you closer to any procurement goal, from cost savings and risk management to quality or process improvement.

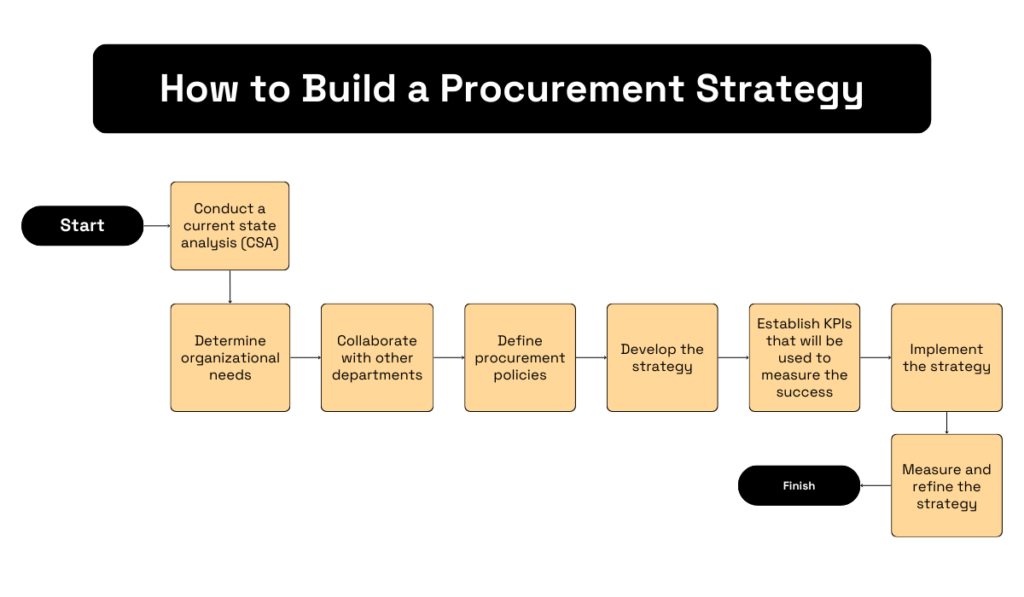

Whatever your priorities may be, you’ll need to follow the following steps to build a good strategy:

Source: Veridion

Just make sure you regularly measure how well your strategy is performing and update it as needed.

After all, organizational requirements and market conditions change, so an effective strategy must constantly be adapted to satisfy evolving circumstances and demands.

That way, you’ll keep operations running smoothly, customers happy, and the business thriving.

Automation of your processes with the help of different tools directly translates to infusing your entire procurement cycle with unparalleled efficiency, accuracy, and speed.

Why?

Because it:

In contrast, clinging to outdated methods and procedures spells all kinds of trouble, warns Ian Nethercot, a Supply Chain Director at IT procurement company Probrand:

“Standing still on digitalisation will undoubtedly leave businesses at a competitive disadvantage. Bogged down by unnecessary admin, a lack of access to live data is leaving buyers struggling to buy at the best times and gain value from every purchase. As a result, they also have less time to spend building strategic relationships with the suppliers that can help them better meet the needs of their organisation.”

It slows everyone down, compromises the quality of work, and blinds you to opportunities for improvement or cost savings.

Consider supplier sourcing as an example.

The manual approach to this important process isn’t just painfully sluggish but also restricts access to critical data.

After all, there are only so many supplier websites you can browse, calls you can take, or industry events you can attend in a limited amount of time until you have to settle on a vendor.

Keith Hartley, CEO of LevaData, an AI-powered software platform for direct material sourcing, agrees that manual sourcing just doesn’t cut it in today’s fast-paced world.

Illustration: Veridion / Quote: CPOstrategy

Automated supplier sourcing tools, on the other hand, have a much wider reach, allowing you to find truly ideal vendors in seconds.

One such tool is Veridion.

Veridion is an AI-powered supplier sourcing enabler that lets its users tap into a vast global database of suppliers, search based on specific criteria, and create a shortlist of promising candidates.

The best part?

All of that can be done in mere moments.

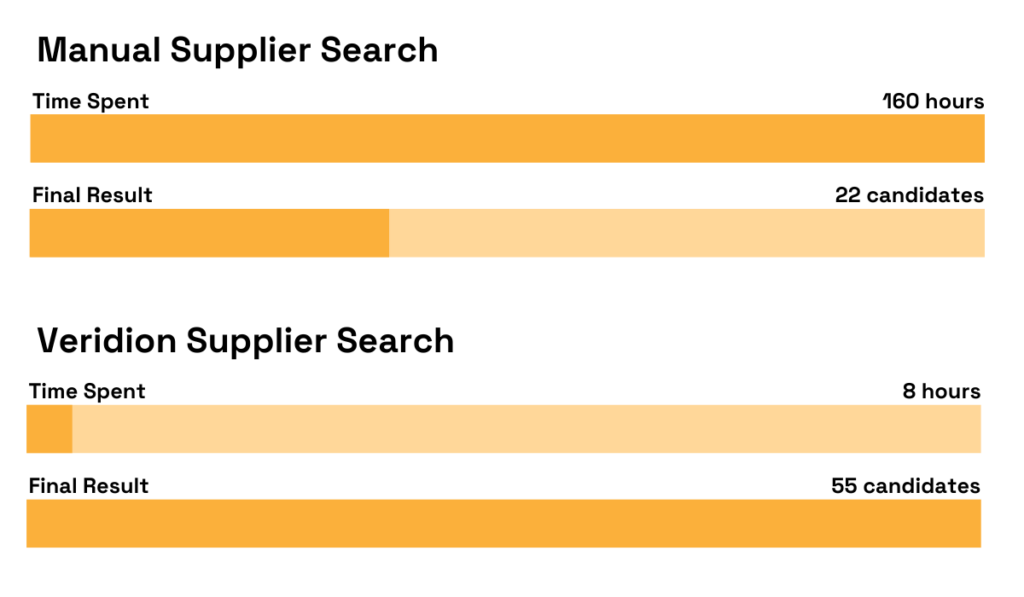

Below, you’ll find a comparison of manual supplier discovery versus using Veridion.

Source: Veridion

The results are striking: Veridion-powered searches uncovered more than double the number of potential suppliers in only a fraction of the time.

It really doesn’t get any more efficient than that.

And remember, sourcing is just one stage in the procurement cycle.

Now imagine unlocking this level of efficiency across all your processes.

Such a transformation would be a real game-changer for the entire procurement function, as well as the business as a whole.

Data visibility means having easy access to and the ability to analyze information about your suppliers, purchasing trends, spending patterns, contract management, and overall procurement performance.

This is absolutely critical for making informed decisions that steer your procurement activities toward more favorable outcomes.

Why?

Because data visibility helps you identify trends and patterns, anticipate future needs, optimize costs, mitigate risks, and much more.

And the findings of the 2024 Keelvar survey confirm this.

According to the survey, 56% of businesses prioritize data-driven decision-making as their top investment to drive growth, attract talent, and minimize risks in procurement.

Illustration: Veridion / Data: Keelvar

For them, access to accurate, timely data is pretty much synonymous with success.

They realize that, without these insights, they essentially operate blind to what’s happening within their companies, relying solely on intuition.

But good data visibility offers another significant benefit to the procurement cycle that is often overlooked: it demonstrates procurement’s value across the organization.

As Derek Bush, Supply Chain Transformation Leader at IBM, notes, procurement often operates in the shadows compared to other departments, despite its considerable impact on business outcomes.

Illustration: Veridion / Quote: CPOstrategy

With strong data transparency, however, the function can finally showcase its achievements, proving it hits targets and drives results without constantly having to justify every move or beg for more resources.

This eliminates the pressures that can lead to rushed decisions, missed cost-saving opportunities, decreased morale, and high employee turnover, all of which negatively affect the procurement cycle.

So, how do you achieve this data visibility?

The answer is, yet again, through digitalization.

Solutions like e-procurement platforms, for example, gather and consolidate data from every stage of the procurement cycle and then even crunch all the numbers for you as well.

Ingmar Mester, Director of Supplier Management and Sustainability at Hapag-Lloyd, a German international shipping and container transportation company, emphasizes the importance of such data analytics capabilities.

Illustration: Veridion / Quote: Craft

And he’s absolutely correct.

Data visibility isn’t just about compiling and accessing vast amounts of information.

It’s also about turning that information into actionable insights that give you a complete, 360-degree view of your operations and leveraging it to manage your procurement cycle with confidence and ease.

Effective procurement is all about continuously raising the bar, and that’s why keeping a close eye on Key Performance Indicators (KPIs) is crucial.

What exactly are KPIs, you ask?

Put simply, they are the metrics that help evaluate how well all your activities, initiatives, and procedures are performing across every stage of the procurement cycle.

Below, you can see some common KPI examples within three categories: cost control, supplier management, and process efficiency.

| COST MANAGEMENT | SUPPLIER MANAGEMENT | PROCESS EFFICIENCY |

|---|---|---|

| Cost savings | Supplier availability | Procurement cycle time |

| Cost avoidance | Supplier compliance rate | Vendor rejection rate |

| Procurement ROI | Supplier quality | Emergency purchase ratio |

| Spend under management | Supplier defect rate | Purchase order accuracy |

Monitoring KPIs is invaluable, as they provide a quantifiable measure of how well you’re doing and whether or not you’re hitting your targets.

On top of that, they highlight areas where you’re excelling, along with those that might require some further improvement.

For instance, KPIs related to cycle times can pinpoint bottlenecks in approval processes that you need to address.

Similarly, delays in supplier lead times that are beyond acceptable limits may signal there are some inefficiencies within the supplier performance management process or logistics.

Basically, you can think of KPIs as diagnostic tools, revealing where the problems may be and hinting at their root cause.

A good example of a business that prioritizes KPI tracking is Danone, a French multinational food products company.

For them, this process is key to effective supplier management, explains their CPO, Jean-Yves Krummenacher.

Illustration: Veridion / Quote: Procurement Mag

After all, they work with so many different suppliers.

KPI monitoring is the only way for Danone to keep a close eye on their safety, quality, as well as service levels, and ensure strong, transparent, long-term seller-buyer relationships.

The bottom line?

You can’t really expect to know how to even begin to improve your procurement cycle if you don’t measure your performance first.

That’s where KPIs tracking and analysis step in, giving you clear insights into your processes, facilitating benchmarking, and, ultimately, pushing you toward smoother, more efficient operations.

Whether through a digital database, cloud-based system, or physical filing, consolidating procurement-related documentation in a single organized repository is an absolute must.

This repository should include all vital documents such as:

Why does this matter?

Well, for starters, it significantly boosts the efficiency of the procurement cycle.

When all documents are stored in one central location, employees can easily find all the information they need without wasting time searching through multiple systems or locations.

Plus, a centralized repository helps ensure that everyone in the company is accessing the most up-to-date versions of documents, reducing errors that occur when outdated versions are used.

Not to mention that teams across all company departments can collaborate more effectively when the documentation is properly stored.

They can work on the same file simultaneously, track changes, and comment on drafts without confusion over multiple versions.

Talk about efficiency.

And let’s not forget compliance—having all your documents in one spot makes it easier to demonstrate that you’re adhering to the internal rules and regulatory standards.

Kiran Menghnani, director of Tipico Services LTD, a part of the online iGaming and sports betting brand Tipico Group, can attest to that:

“There are always particular questions auditors ask, and to be in a position where we couldn’t answer, or couldn’t find the answer, was not an option. I didn’t want to be running around looking for answers, it should be readily available… but wasn’t. And so, this was the acknowledgment needed to start centralizing documentation and the move towards a contract life cycle management process.”

Before centralizing their documentation, they would really struggle during audits because, essentially, retrieving the right documents was like searching for a needle in a haystack.

But once they changed that and established a reliable single source of truth, suddenly, finding the information they needed was a breeze.

Now, we mentioned that documentation can be centralized using both digital solutions and physical storage.

But, are both truly equally effective?

Unfortunately, no.

Organizing your documents manually definitely has its limitations.

It restricts access to those physically present at the storage location, makes document retrieval slower, and requires significant physical storage space, which can be costly and impractical for large volumes of documents.

Digital solutions, such as document and contract management systems, or even procurement management tools in general, are far more efficient, no doubt about it.

They offer 24/7 access from any location with an internet connection, can be searched using keywords, require no physical space, and maintain a detailed history of all document versions and updates.

Source: Promena

So, if you’re aiming for easy, yet controlled access to critical data, reduced paper usage, and decreased risk of document loss or damage, such systems are an ideal solution for you.

Overall, centralizing procurement-related documents in a well-organized repository—preferably digital—is undoubtedly the key to easier communication, regulatory compliance, and efficient operations across the entire procurement cycle.

Isn’t it remarkable how much of a difference an effective organization can make?

At this point, you might agree that solving common purchasing challenges and taking your procurement cycle to whole new heights isn’t such a daunting task after all.

Sure, it takes work, patience, and the right digital tools, but it’s entirely achievable.

Plus, all that effort truly pays off.

How do super-efficient, risk-free operations sound?

How about strategic, long-term supplier relationships or significant cost savings?

By working on your own procurement cycle, you can definitely unlock all these perks and more.