6 Ways To Master Indirect Procurement

Managing indirect procurement is often sidelined because indirect spend doesn’t directly affect your core product.

But those seemingly small purchases—office supplies, software licenses, facility maintenance—can quickly add up.

Suddenly, costs spiral and suppliers multiply, leaving you scrambling to cut expenses.

And you probably know that getting indirect procurement under control could save you time and money, but where do you begin?

Don’t worry.

Today, we’ll share six practical ways to master indirect procurement.

By the end, you’ll feel more in control and ready to sharpen your indirect procurement strategy.

It’s true that indirect procurement doesn’t directly influence your end product.

But think about it—could your business operate without electricity, office supplies, or the right talent brought in by your HR team?

These are all essential expenses, and ignoring them is a costly mistake.

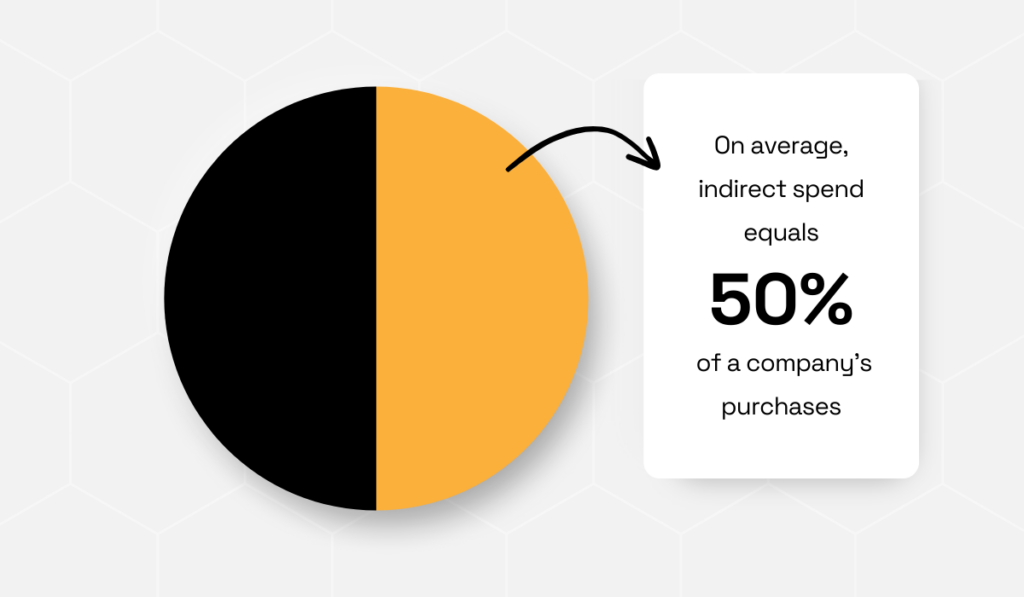

In fact, indirect spend can account for around 50% of your total expenditure.

Illustration: Veridion / Data: Procurement Academy

So, neglecting it is like ignoring half of your budget, which can lead to escalating costs, delayed services, and missed opportunities for savings.

What’s more, if you don’t control your indirect spend with different suppliers, you can face poor supplier performance and disrupted operations.

And the longer you leave indirect spend unchecked, the harder it becomes to rein it in.

But when you recognize its importance, you can achieve great things.

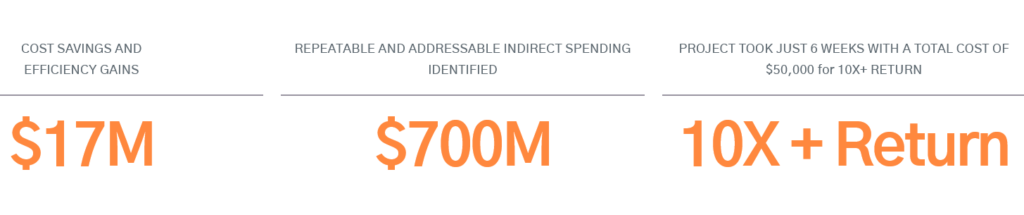

Consider one of the largest quick-service restaurant chains in the U.S.

They identified $17 million in cost savings after implementing a spend management solution to better manage indirect spend.

They also identified another $700 million of repeatable and addressable indirect spend for potential savings, all within six weeks.

Source: Sirius Solutions

If they had continued to ignore their indirect spend, those hidden costs would have continued to eat into their profits.

Their quick win is the perfect example of how effectively managing your indirect spend can bring you massive value.

And recognizing this is the first step in mastering indirect procurement.

Now that you understand the stakes, let’s dive into the specific steps you should take to control indirect procurement better.

Before you can truly get a handle on indirect procurement, you first have to assess your current suppliers.

Think of it as an audit of your supply chain: you need to understand where your money is going and how well your suppliers are performing.

Start by reviewing all your existing contracts with suppliers.

Go through each one carefully and look for opportunities to renegotiate terms.

For instance, you might realize that some of your contracts were made when your business had different needs or required lower volumes of a specific product, and now you can leverage better terms.

Or you may even find that you’re locked into contracts that renew automatically, draining your resources without you even realizing it.

If you discover a contract that no longer serves your interests, consider closing it out or even terminating it.

Faiq Ali, Procurement Director at Corporate Buyers, shares the steps to take if that’s the case:

“Conduct a thorough review of the contract, documenting the completion of all terms, including deliveries, payments, and any post-contract obligations. Communicate clearly with the supplier about the termination, providing ample notice as per the contract terms. Resolve any outstanding issues or disputes amicably. Conduct a formal contract closure meeting or send a closure notice to officially mark the end of the contract.”

Once you’ve reviewed the contracts, it’s time to evaluate supplier performance.

Are the suppliers living up to the agreed terms?

This step is crucial because, even if you have great deals on paper, if the supplier isn’t delivering the quality or service you need, it’s costing you more in the long run.

So, how do you measure supplier performance?

For starters, you need clear criteria against which to compare how well they’re doing.

Factors like delivery times, service quality, compliance with regulations, and pricing consistency are all good starting points.

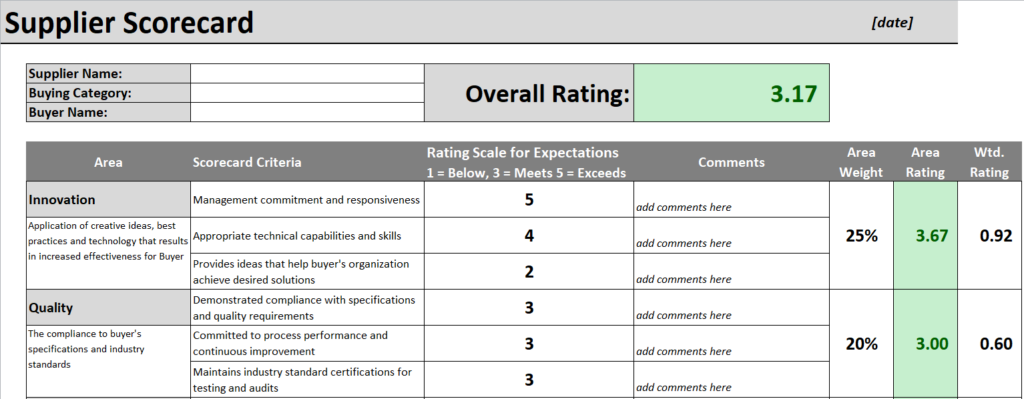

A useful tool for this is a supplier scorecard, like the one you see below.

It allows you to rate suppliers across multiple categories, from innovation and quality to pricing and delivery.

Source: RK

You can then compare these ratings and decide whether to stick with a supplier, renegotiate, or look elsewhere.

This process may sound time-consuming—especially in indirect procurement, where you often work with tens, if not hundreds of suppliers—but it’s well worth the effort.

After all, you can get the most value for your money and strengthen your overall procurement strategy only if you know which suppliers are worth working with.

Creating a strategic sourcing plan for indirect spend starts with understanding the nature of your suppliers.

Unlike direct suppliers, who you might interact with regularly, indirect suppliers often provide services or products less frequently.

Naturally, this leads to weaker, more transactional relationships.

But here’s the thing: even if these suppliers aren’t in the picture as often, their role is still crucial to your business.

So, you should have a good strategic sourcing plan in place for indirect suppliers as well.

After all, deepening these relationships is essential for managing your indirect spend more effectively.

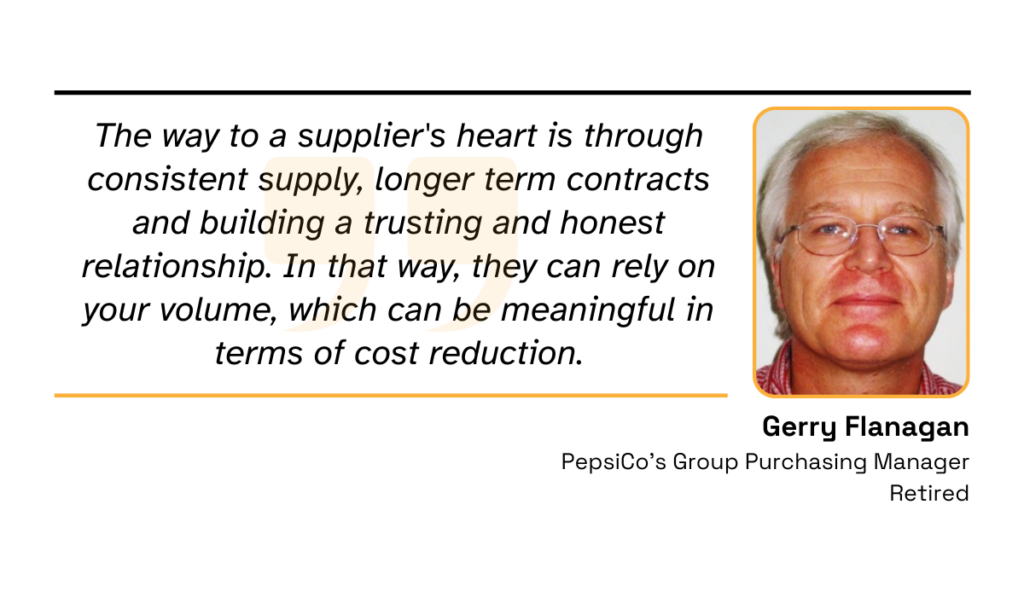

And Gerry Flanagan, retired PepsiCo’s Group Purchasing Manager, shares the perfect recipe to achieve that.

Illustration: Veridion / Quote: LinkedIn

You, on the other hand, get more stability but also better deals.

When you collaborate closely with suppliers, you’re more than just a customer.

They’re invested in your success, so they’re more likely to adapt to your needs, provide better service, and offer consistent value over time.

And this is what strategic sourcing is all about.

So, it isn’t just about finding the cheapest option.

Rather, it’s about finding suppliers who align with your long-term goals, can meet your evolving requirements, and provide quality consistently.

That said, there are a few challenges you need to watch out for in your strategic sourcing.

David Mortaz, who has worked with giants like Facebook, Apple, and HP, offers some important insights he gained when working as a strategic sourcing consultant.

For starters, he points out that suppliers often push to know if you’ve budgeted for a project.

Illustration: Veridion / Quote: LinkedIn

While it may feel like harmless information to share, revealing your budget early can severely limit your ability to negotiate favorable terms.

Therefore, it’s always best to keep your budget confidential until the final stages of negotiation.

Another pitfall?

Vendors often push for quick decisions, especially at the end of a quarter when they’re eager to close deals.

This pressure can also lead to rushed decisions and poor terms.

Moreover, It’s easy to get lured into buying more than you need just because the vendor offers a larger discount.

However, you should stick to your actual needs, and not let the vendor drive the negotiation.

Equally important, your strategic sourcing team should always control the timeline—not the vendor—to get the best possible outcome.

Mortaz also emphasizes the importance of confidentiality when selecting your final supplier.

If vendors know they’re your top choice too early, they may stop offering better terms.

Keeping your shortlist private until the end of negotiations helps ensure you get the most concessions possible.

Finally, he suggests not limiting yourself to just a couple of vendors.

Even if your indirect spend isn’t huge, having more suppliers involved in the bidding process gives you leverage.

Let’s say you need a specific product or service, but you’re stuck with only one vendor.

That vendor knows they’re your only option, and suddenly, you’re forced to accept terms you’re not happy with.

This is exactly the kind of situation you want to avoid in indirect procurement.

So, how do you make sure you’re not cornered like this?

By having enough supplier options from the start. This ties directly into your strategic sourcing plan.

The more suppliers you have to choose from, the stronger your position when it comes to negotiating favorable terms.

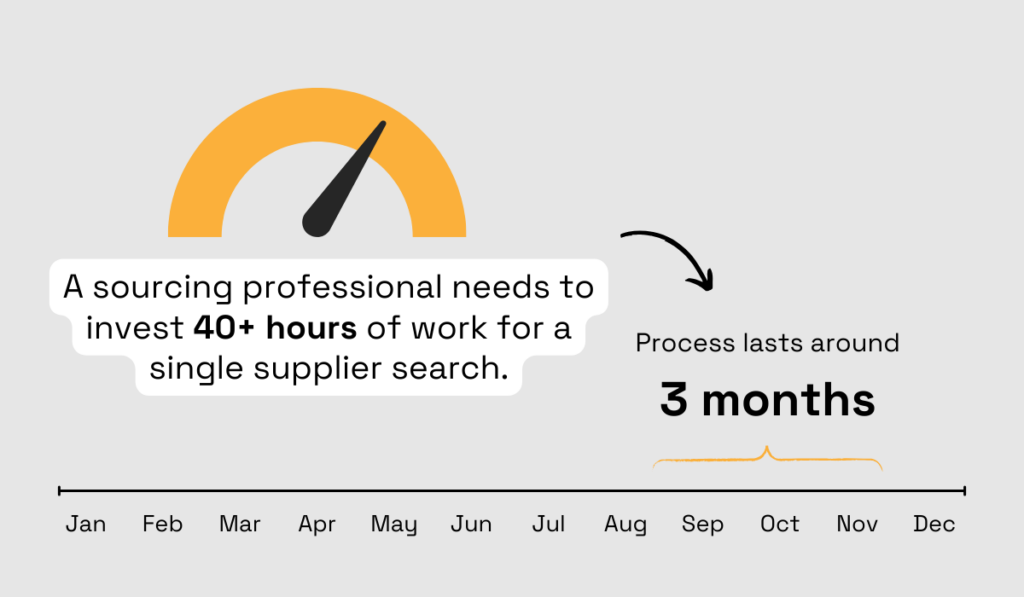

However, you have probably experienced yourself just how time-consuming and resource-intensive it is to search for suppliers and have accurate data on them.

It can take days, weeks, sometimes even months.

Illustration: Veridion / Data: McKinsey

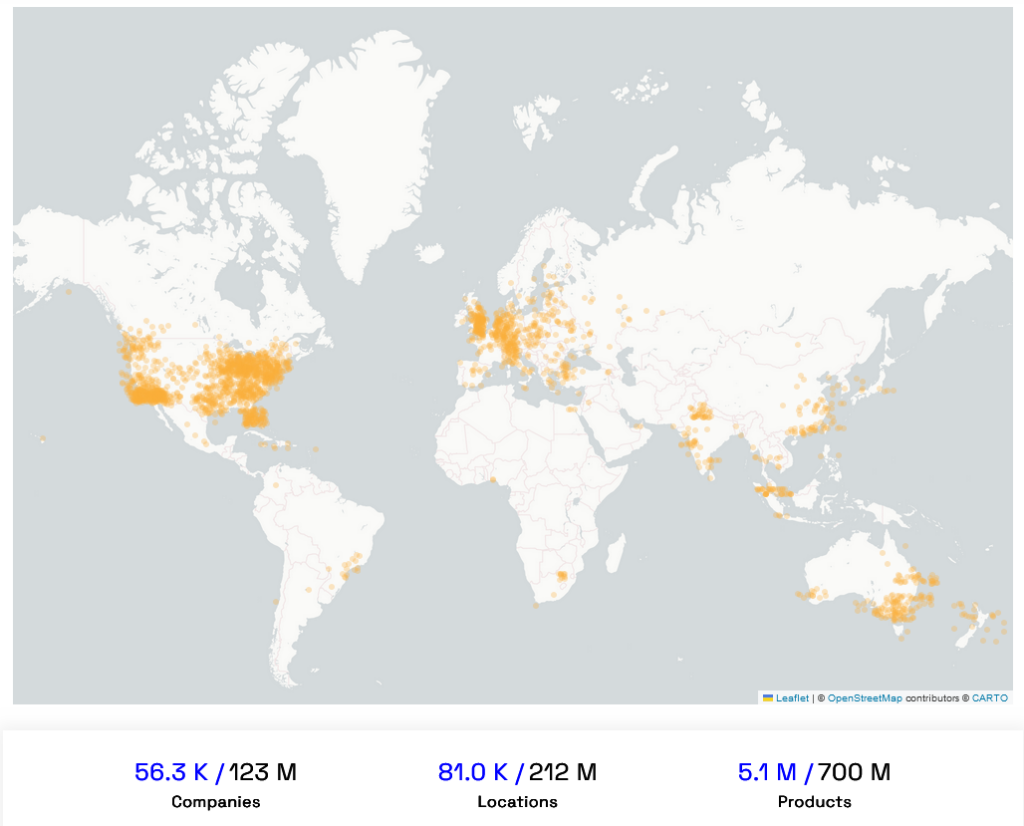

Fortunately, that’s where big data platforms like our Veridion come in.

You simply enter your criteria into our service, and Veridion presents a tailored list of suppliers that match your needs in seconds.

Whether it’s suppliers with ISO certifications, sustainability standards, or specific compliance requirements, Veridion will help you find exactly what you’re looking for.

You can see how it works in the video below:

Source: Veridion on YouTube

It’s fast, it’s efficient, and it gives you access to an enormous database of over 100 million companies across 212 million locations.

Source: Veridion

And the best of all?

Our data is always fresh and accurate.

Source: Veridion

There’s really no better way to ensure you always have options at your fingertips.

Now, you might be wondering: isn’t supplier consolidation the best practice for indirect spend management?

And doesn’t that sound like the opposite of what we’re discussing here?

Well, here’s where it all connects.

Supplier consolidation is about working closely with a select few suppliers who can deliver multiple services or products, building stronger relationships, and achieving economies of scale.

On the other hand, having access to a larger pool of suppliers is your safety net.

It gives you the flexibility to compare offers and ensures you’re not over-relying on one supplier, which helps you manage risks better.

The key is to balance the two.

Consolidate where it makes sense, but always keep enough options in your back pocket to maintain negotiating power.

And it all becomes easier when you can find potential suppliers with just a few clicks.

Remember, building strong supplier relationships is just the beginning of better indirect procurement.

To get the most long-term value from those relationships, you need a solid framework in place—one that dictates how purchases are made.

It should include key elements like approval workflows, vendor selection criteria or pre-approved supplier lists, and purchase order processes.

These policies will guide your procurement cycle and provide a clear structure for all stakeholders.

They will know which suppliers to work with, how to manage purchases, and how to comply with internal protocols.

This will reduce errors, curb unnecessary spending, and maintain consistency across the organization.

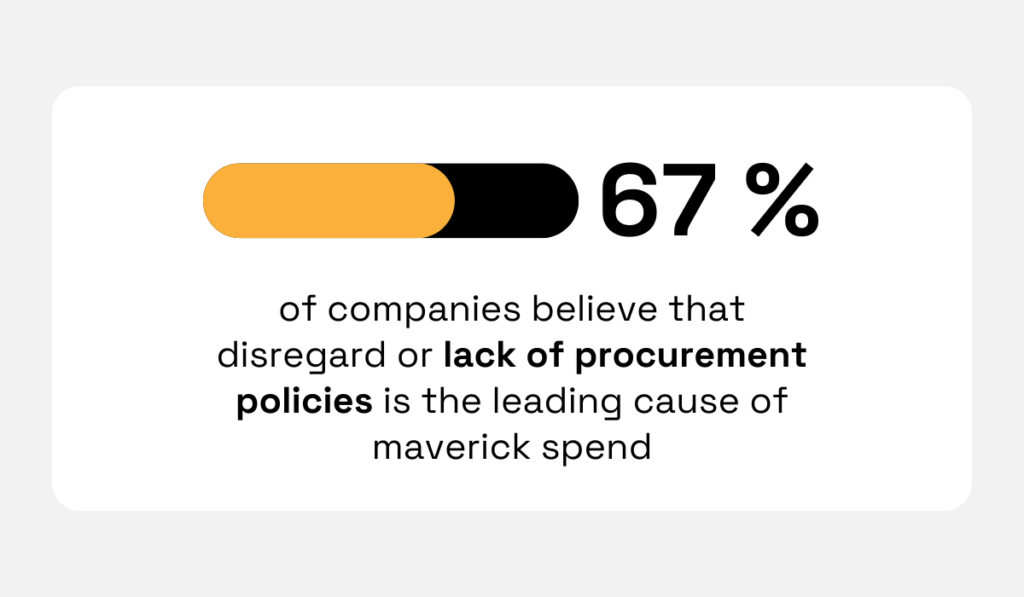

But why is sticking to these rules and policies so important?

Well, because a lack of procurement policies or disregarding them is the leading cause of maverick spend, according to 67% of companies.

Illustration: Veridion / Data: Basware

This type of spending isn’t just costly, though.

It’s also a way of “betraying” the suppliers you’ve worked hard to negotiate deals with, as it undermines the value of your contracts.

However, if you establish, document, and share spending policies with your team and other stakeholders, you can drastically reduce maverick spending.

Now, how do you decide where to focus your spending policy efforts?

This is where the well-known Pareto Principle can help you, says Anthony Clervi, Principal Owner of the group purchasing organization UNA.

He emphasizes that focusing on the critical 20% of suppliers or categories that represent 80% of your spend will deliver the most impact.

Illustration: Veridion / Quote: Una on YouTube

But here’s the thing: your spending policies will only work if they’re clearly communicated and followed consistently across your organization.

This brings us to an often-overlooked aspect of indirect procurement—stakeholder engagement.

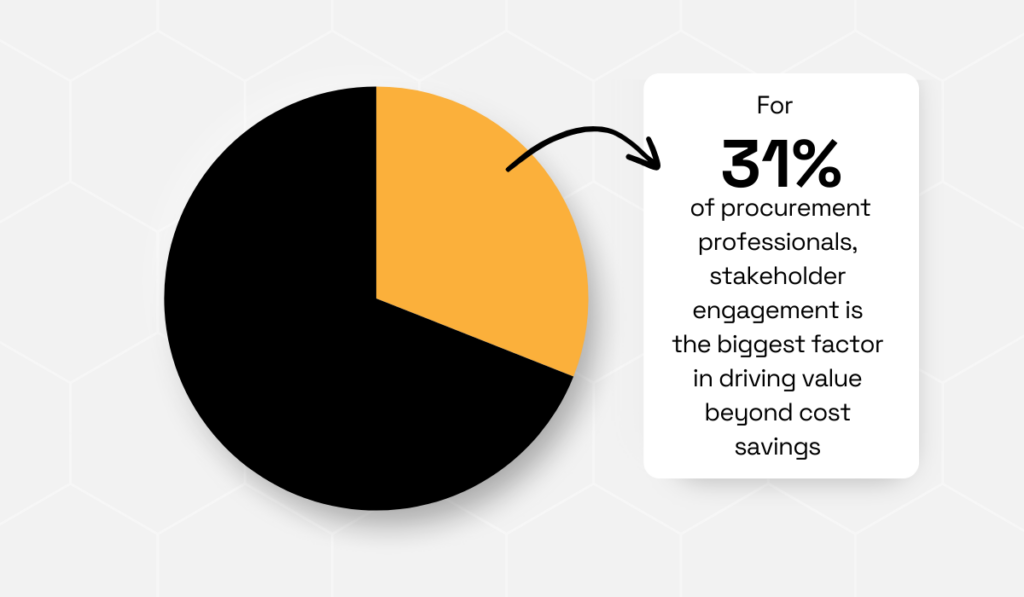

In a recent webinar about indirect procurement in 2024, 31% of participants identified stakeholder engagement as the biggest factor in driving value beyond cost savings.

This was also the most popular enabler.

Illustration: Veridion / Data: CASME

Justin Virden, Executive Director and Global Head of Indirect Procurement at Amgen and one of the key speakers, gave valuable insight on this point:

“Indirect procurement is a broad and diverse set of services and capabilities that touch a lot of the functions in your company. You need to really invest time in understanding your stakeholder map. And this isn’t just knowing who the people are but really understanding what their priorities are and how they take in information.”

In other words, policies only work if everyone, from marketing to manufacturing, is fully on board.

Moreover, every team has different priorities, but engaging with them from the start ensures they understand and follow the same procurement guidelines.

This makes the entire process smoother, especially when dealing with indirect spend, which often spans multiple departments.

Clear communication will help keep your procurement team and other stakeholders aligned, ultimately improving how your organization manages indirect spend.

And by reinforcing the importance of these policies, you will ensure compliance, reduce rogue spending, and build a more efficient procurement function.

So far, we’ve discussed the importance of identifying the right suppliers, documenting spending policies, and building strong relationships.

But how do you make sure all of these strategies work seamlessly, without getting bogged down in complexity?

The answer lies in procurement automation.

When you centralize and automate your procurement processes, everything we’ve talked about falls into place.

Automation ties together supplier selection, compliance with spending policies, approval workflows, and stakeholder engagement.

Ultimately, this makes procurement not just easier but more efficient and consistent.

Let’s start with visibility.

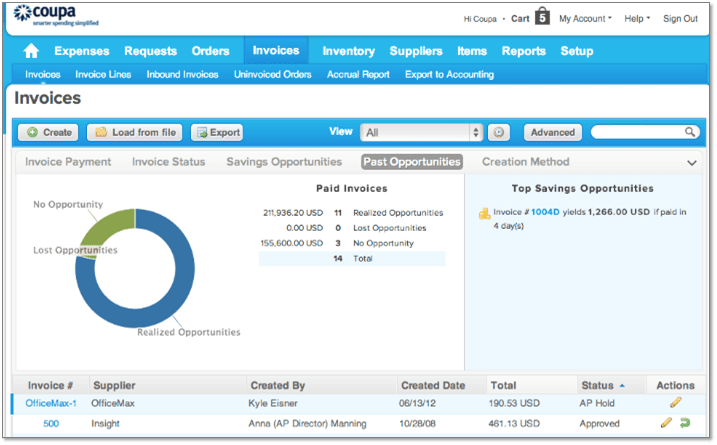

Centralized procurement platforms or procure-to-pay (P2P) systems, like the one below, give you full visibility across all purchasing activities in one place.

Source: Select Hub

You don’t have to chase down purchase orders or worry about whether your spending policies are being followed.

Automation ensures that everything, from sourcing to invoicing, flows through the same system.

Sometimes, you need just a few clicks to make a purchase from vetted suppliers.

For example, guided buying catalogs and automated workflows can help you here.

Need office supplies? A catalog of pre-approved vendors is just a click away.

Looking to finalize a purchase? Automated approval workflows ensure that every purchase meets your standards.

This level of consistency helps prevent errors and rogue spending while ensuring you always work with the right suppliers under the right terms.

This also removes silos between departments, everyone follows the same rules, and spend data can be easily collected.

All this together leads to significant time and cost savings.

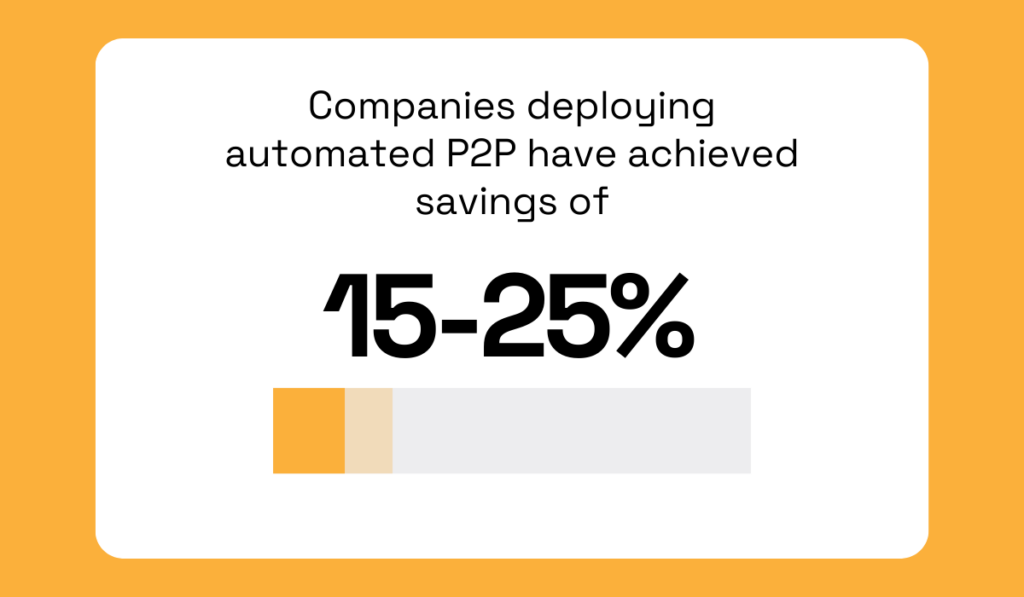

McKinsey has found that companies using automated P2P systems reduce their processing times from days to minutes and achieve savings of 15-25% per transaction.

Illustration: Veridion / Data: McKinsey

That’s time and money saved, freeing up your team to focus on more strategic work.

Let’s conclude with a great example from Jabil, a global manufacturing giant that achieved great things by mastering its indirect procurement.

They were spending over $2 billion annually on indirect procurement but had little visibility into where that money was going.

By centralizing and automating their procurement through a cloud-based procurement platform, they transformed their entire process.

In just 18 months, they increased electronic invoicing from 5% to over 50%, saving time and reducing complexity.

Now, 90% of their purchases are processed through the platform, which gives them better control, governance, and efficiency.

But all of this wouldn’t have been possible without one key aspect we mentioned earlier—stakeholder engagement from the beginning.

Heidi Banks, Senior Director of Global Procurement at Jabil, notes:

Illustration: Veridion / Quote: Coupa

The bottom line?

Automation ties everything together—from spending policies and compliance to cost savings and supplier relationships.

With good governance, it helps you manage your spend better and get the most out of your indirect procurement.

Yes, indirect procurement is often overlooked, but it has immense potential to drive value.

By mastering key strategies—like building strong supplier relationships, establishing clear spending policies, and centralizing processes with automation—you can transform indirect spend into a powerful lever for cost savings and operational efficiency.

The key takeaway?

Treat indirect procurement with the same strategic focus as direct spend.

Embrace technology, engage stakeholders, and always keep value creation at the forefront.

It will pay off sooner than you think!