5 Best Practices for Measuring Procurement Savings

In procurement, proving your team’s value often boils down to one crucial question: How much are you saving?

Yet, many procurement professionals struggle with savings, often facing challenges like inconsistent tracking and unclear data.

If you’re looking for better ways to quantify your procurement team’s impact, you’re in the right place.

This article aims to simplify measuring procurement savings.

We’ll walk you through five essential practices, from setting clear objectives and working closely with your finance team to identifying the right metrics and benchmarking against industry standards with accurate data.

By the end of this article, you’ll have a solid framework to measure and present your savings.

Without further ado, let’s get started.

Any successful process begins with a solid plan, and measuring procurement savings is no exception.

Establishing clear metrics and objectives right from the start is crucial for several reasons.

One of the best ways to create effective objectives is to follow the SMART framework shown below.

Source: Veridion

A SMART procurement objective would be something like “reduce raw material costs by 8% within the next fiscal year by consolidating suppliers and renegotiating contracts.”

This is a specific, measurable, achievable, and time-bound goal.

On the other hand, a non-SMART objective might be to “improve supplier relationships.”

While this is a worthy goal, it lacks specificity and clear metrics, making it difficult to track progress or determine success.

Speaking of broader goals, it’s essential that your procurement objectives align closely with your organization’s overall strategic objectives.

For instance, if the company’s goal is to reduce overall costs by 5%, the procurement team might set a target to reduce spending by 10%.

It’s important to align these goals so procurement can directly contribute to achieving a company-wide initiative.

Once you’ve aligned your goals, you’ll need to select the main strategy to measure your progress.

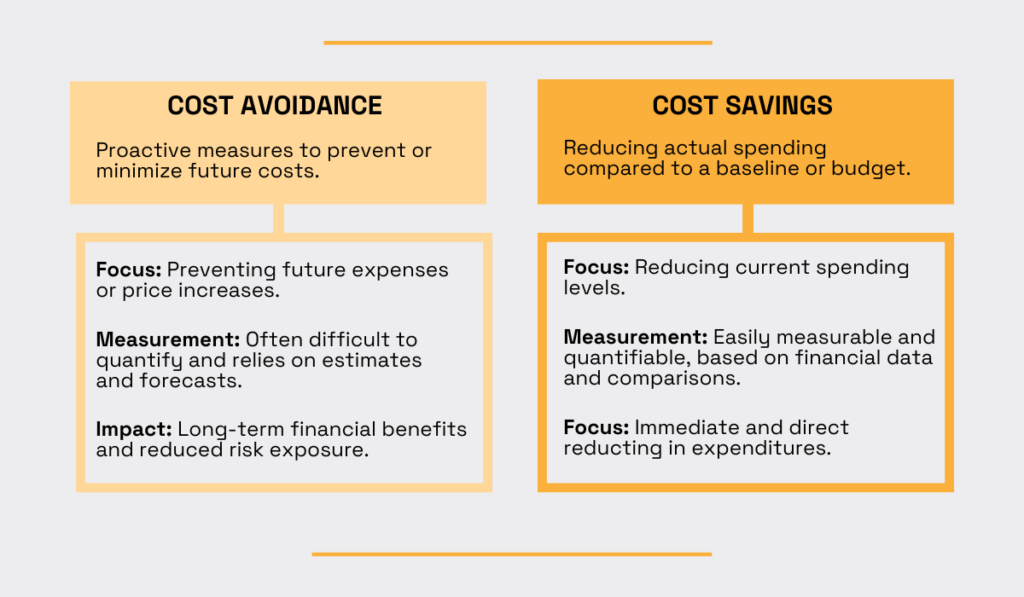

Two common options are cost avoidance and cost savings.

Source: Veridion

Cost avoidance focuses on preventing future expenses or price increases, while cost savings refer to actual reductions in spending compared to a baseline.

Depending on your specific objectives, you might measure one or both of these metrics.

For instance, renegotiating a contract to prevent a price increase would be cost avoidance, whereas securing a discount on an existing contract contributes to direct cost savings.

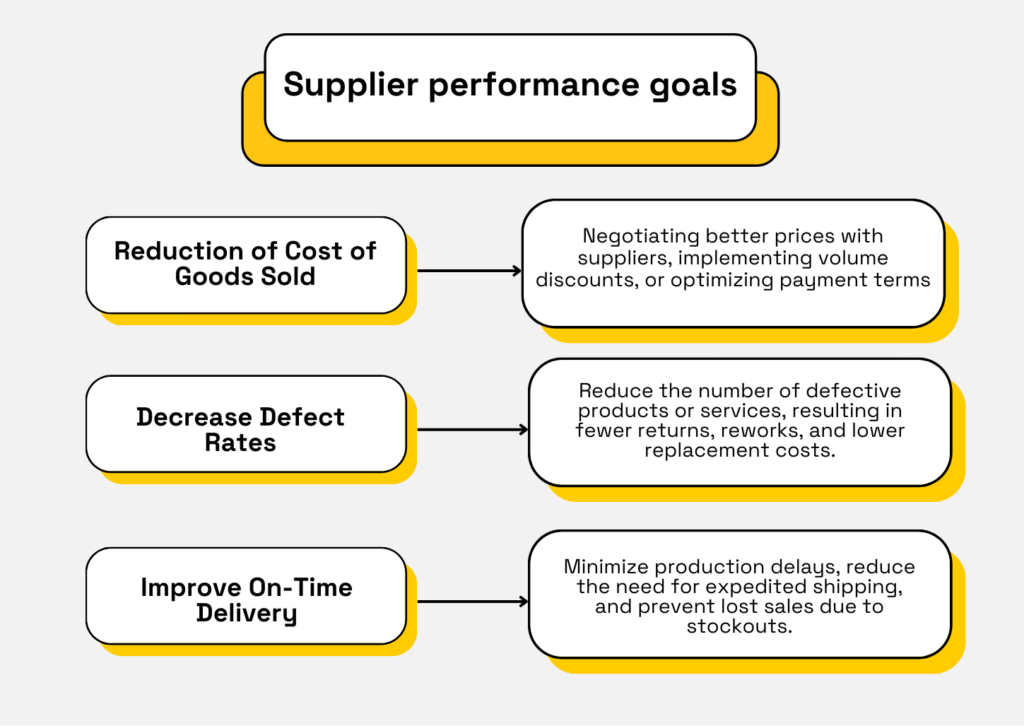

Another important category is supplier performance goals.

Source: Veridion

These goals can directly or indirectly impact savings.

For example, reducing the cost of goods sold (COGS) has an immediate financial impact.

Other supplier-related metrics, such as decreasing defect rates or improving on-time delivery, can indirectly contribute to savings by minimizing waste, improving efficiency, and optimizing cash flow.

All in all, by defining clear objectives and aligning them with your organization’s overall goals, you lay a solid foundation for measuring procurement savings and showcasing your team’s impact on the bottom line.

One of the most strategic moves you can make when it comes to accurately measuring procurement savings is forging a strong partnership with your finance department.

After all, finance professionals are the experts in quantifying and reporting financial performance.

And, their collaboration ensures that your measurement methods are aligned with broader organizational goals and financial reporting standards.

However, as anyone who’s worked in both departments knows, there can often be a disconnect between procurement and finance.

One of the biggest challenges is agreeing on what exactly constitutes cost savings.

Let’s examine the differing perspectives in the table below.

| ASPECT | FINANCE PERSPECTIVE | PROCUREMENT PERSPECTIVE |

|---|---|---|

| Focus | Primarily focused on bottom-line impact and recognized financial accounting standards. | Emphasis on total value achieved, including both hard cost reductions and soft savings like efficiency gains. |

| Measurement | Strict financial metrics like year-over-year cost reductions or budget variances. | Includes both financial metrics like price reductions and non-financial metrics like improved supplier performance, reduced risk, or innovation value. |

| Timeline | Typically focused on the fiscal year or reporting periods. | May consider longer-term impacts e.g., multi-year contracts. |

| Priorities | Prioritizes compliance with accounting standards and maximizing shareholder value. | Balances cost savings with other strategic objectives, such as quality, sustainability, and innovation. |

Finance teams often operate within a strict framework of financial metrics, timelines, and priorities so they may struggle to grasp the nuances of procurement processes or the value of non-financial goals.

On the other hand, procurement teams might have difficulty quantifying intangible savings or navigating the complexities of financial reporting requirements.

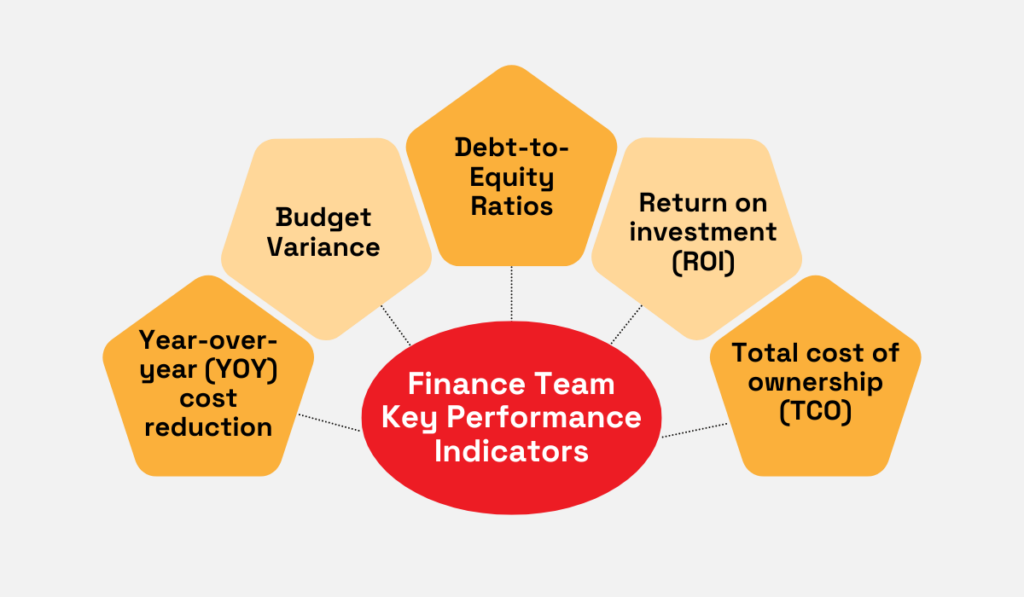

Aligning finance and procurement metrics is a critical first step towards bridging this gap.

Source: Veridion

While finance departments use the above metrics as their daily bread and butter, procurement teams focus on supplier performance metrics, contract compliance rates, cost avoidance, and price variance, among others.

Luckily, these metrics can be directly linked to financial goals.

For instance, reduced lead times and improved supplier performance often lead to lower costs.

Similarly, proactive contract management reduces the risk of cost overruns in the long term.

So the goal should be to translate procurement team initiatives to the finance team, and vice versa.

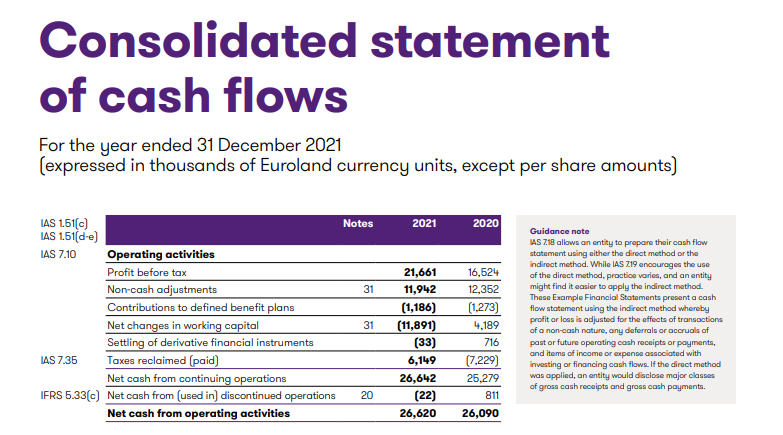

Once these teams start speaking the same language, procurement teams can gain valuable insights into financial reports and statements.

These reports include balance sheets, income statements, financial and budget reports, cash flow statements, regulatory filings (e.g., 10-K, 10-Q for U.S. companies), etc.

Source: Finspect

Procurement teams can leverage this information to gain a deeper understanding of the company’s overall financial health, identify areas for improvement, and make more strategic decisions.

Only through actively engaging with financial data and reports, procurement teams become not just cost centers but value-generating partners in the organization’s financial success.

So try and foster a collaborative relationship between procurement and finance to create a unified front that drives both operational and financial efficiency.

In the previous section, we touched on how finance teams often focus on strict financial metrics when measuring savings.

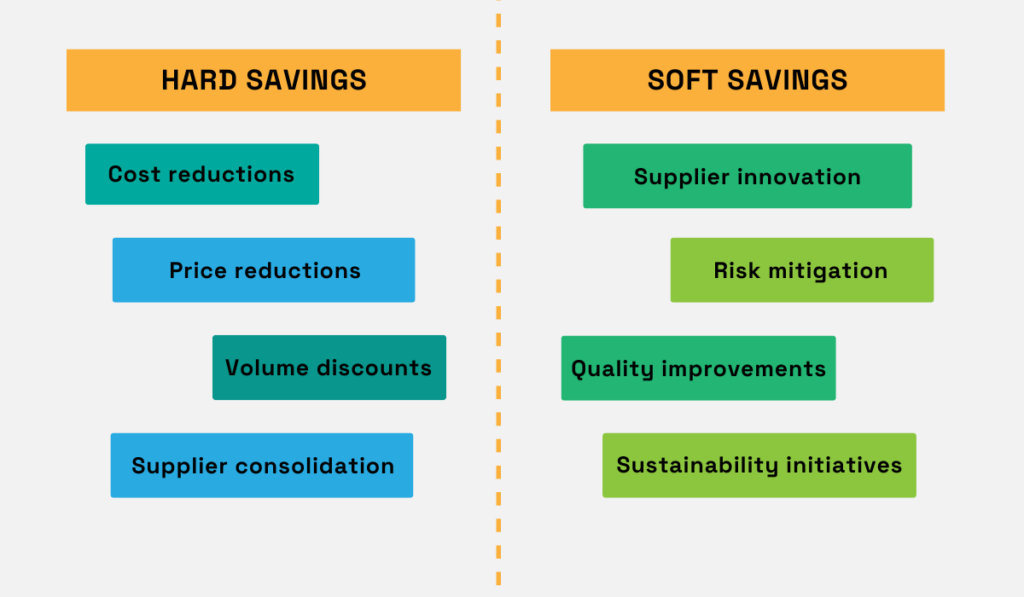

These are commonly referred to as “hard savings,” and while they’re undoubtedly important, they don’t tell the whole story.

Due to the multifaceted nature of procurement processes and strategies, it’s equally crucial to measure “soft savings” to capture the full impact of your team’s efforts.

Let’s take a closer look at these two distinct types of savings.

Source: Veridion

Hard savings are the tangible, bottom-line results that everyone understands.

This could involve measuring direct price reductions achieved through negotiation with suppliers.

Or, it might involve savings realized through supplier consolidation, where you strategically reduce your supplier base to leverage volume discounts and streamline operations.

Soft savings, on the other hand, are less tangible and often harder for other departments to grasp.

These savings can be significant, but they require a different approach to measurement.

Let’s consider supplier innovation as an example.

By collaborating with innovative suppliers, you might unlock new processes or technologies that lead to significant long-term cost reductions and even revenue increases.

The same principle applies to other soft savings categories.

Whether it’s risk mitigation efforts that prevent costly disruptions or process improvements that boost operational efficiency, finding ways to quantify these benefits is crucial.

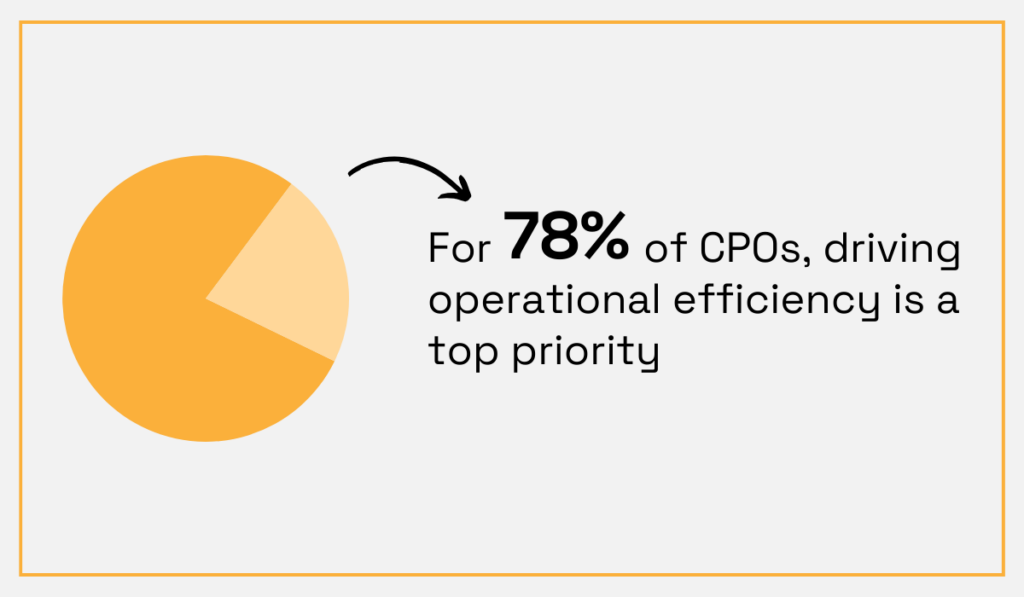

Interestingly, Deloitte data shows that CPOs are increasingly focused on driving operational efficiency.

Illustration: Veridion / Data: Deloitte

In fact, this focus on efficiency surpasses cost savings, which is only 76.4%.

This suggests that the benefits of soft savings are readily apparent to procurement professionals, and it’s essential to communicate these advantages to other parts of the organization.

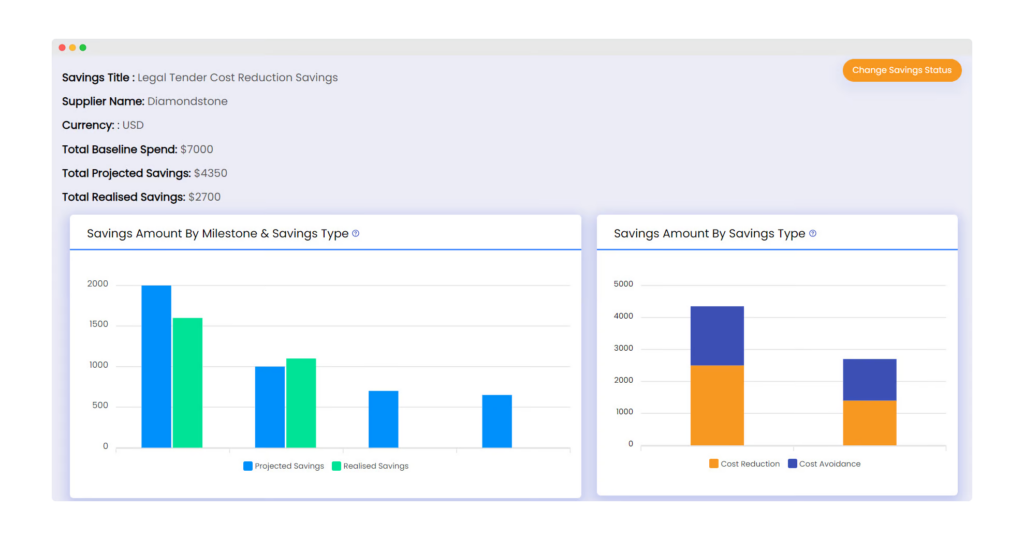

To help measure both types of savings, consider using software solutions like Oboloo.

Source: Oboloo

Oboloo offers a range of features designed specifically for measuring procurement savings.

It enables you to track and compare projected savings with actual realized savings, go into different savings categories, and more, ultimately helping you gain a comprehensive view of your team’s impact.

Measuring both hard and soft savings, helps you paint a more complete picture of procurement’s contribution to your organization’s financial health and operational efficiency.

When it comes to measuring anything, data accuracy is paramount.

This is especially true in procurement, where precise calculations are essential for tracking savings and making informed decisions.

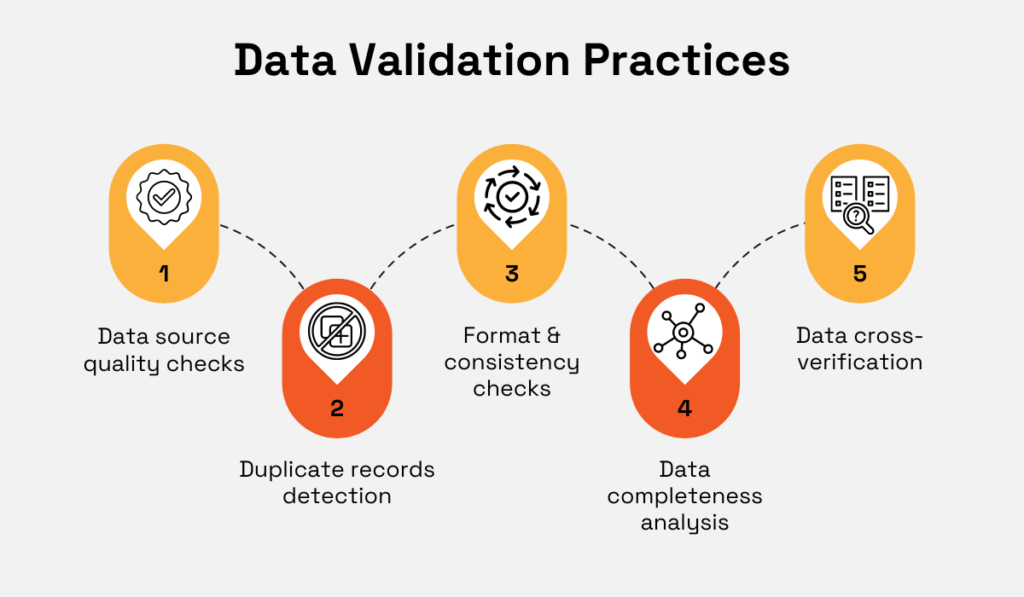

Validating the accuracy and integrity of your procurement data ensures that your calculations are based on reliable, consistent, and up-to-date information.

To achieve this high level of data integrity, it’s important to follow data validation best practices, some of which are illustrated below.

Source: Veridion

Straightforward tasks like cleansing data can make a big difference.

This involves detecting and removing duplicate records, as well as checking for inconsistencies in data formats.

These steps ensure that your data is clean and standardized, making it easier to analyze and compare.

Once your data is tidy, you can move on to more in-depth validation techniques.

For example, quality checks can involve evaluating the reliability and accuracy of the sources you’re using.

You should also focus on the accuracy of your supplier data.

Validating supplier information ensures you’re working with reliable partners who can meet your quality and delivery standards, which is crucial for risk mitigation and cost control.

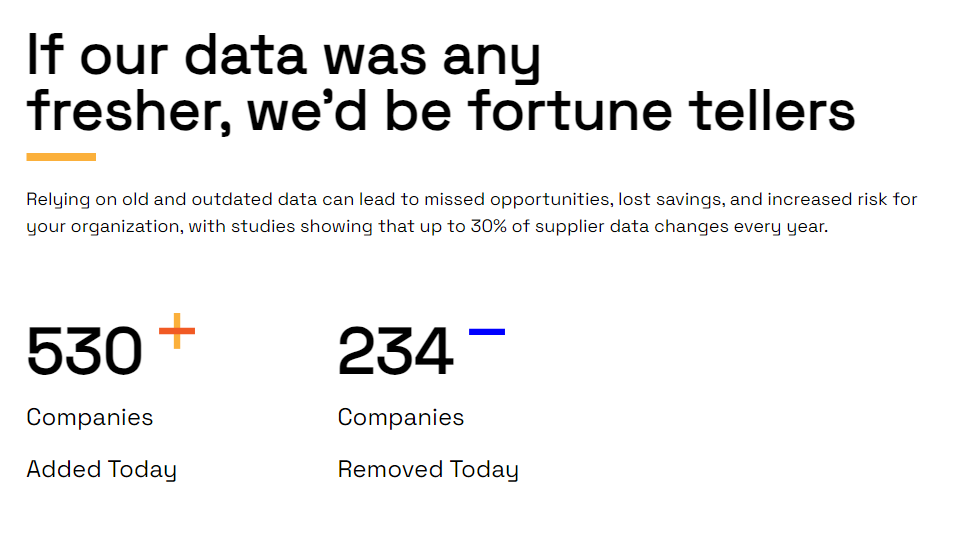

For this purpose, you can leverage our supplier sourcing enabler tool, Veridion.

Source: Veridion

We boast a vast database of over 80 million companies worldwide, constantly updated weekly.

New companies are added, and outdated or inaccurate information is removed, guaranteeing that you always have access to the most current and reliable supplier data.

This comprehensive database can be used to clean up your existing supplier data, ensuring it’s accurate and up to date.

You can also enrich your data with additional information with our Match & Enrich API, if you’re looking for additional data points for a deeper understanding of your supplier landscape, enabling more informed decision-making.

Source: Veridion

The use cases are endless.

For example, if implementing sustainable practices is one of your objectives for procurement savings a priority, you can utilize Veridion’s data to verify the environmental credentials of your preferred suppliers or find new suppliers that match your criteria.

Or, if you’re seeking local sourcing options, you can integrate Veridion’s data with your internal spending data to identify potential suppliers within your geographic region.

So, by diligently validating your procurement data and leveraging tools like Veridion, you create a solid foundation for accurate measurement, informed decision-making, and ultimately, increased procurement efficiency.

Finally, let’s discuss benchmarking—the practice of comparing procurement data and performance metrics to industry standards.

Think of it as checking in with the rest of the industry to see how you stack up.

This comparison offers valuable insights into your organization’s strengths and weaknesses and helps you understand where you have room for improvement.

Michael Van Keulen, CPO of Coupa, a spend management platform, aptly describes the importance of benchmarking.

Illustration: Veridion / Data: Coupa

Benchmarking is particularly useful when measuring procurement savings.

By comparing your achievements against industry standards or peer organizations, you gain a clear understanding of where your performance stands relative to others.

This external perspective provides valuable context for interpreting your internal data and helps you identify areas where you can optimize your processes and drive greater value.

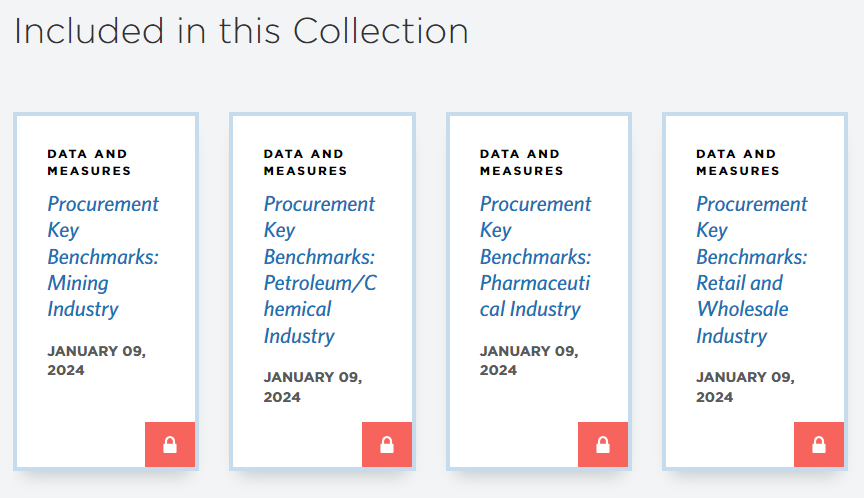

Luckily, there’s no shortage of resources available to assist with benchmarking your procurement metrics.

One excellent option is APQC (American Productivity & Quality Center) which publishes key procurement benchmarks regularly updated with the latest data.

Source: APQC

APQC provides procurement data across diverse industries, from mining and pharmaceuticals to retail and manufacturing.

This allows you to zero in on benchmarks specific to your sector, gaining insights that are highly relevant to your organization’s operations.

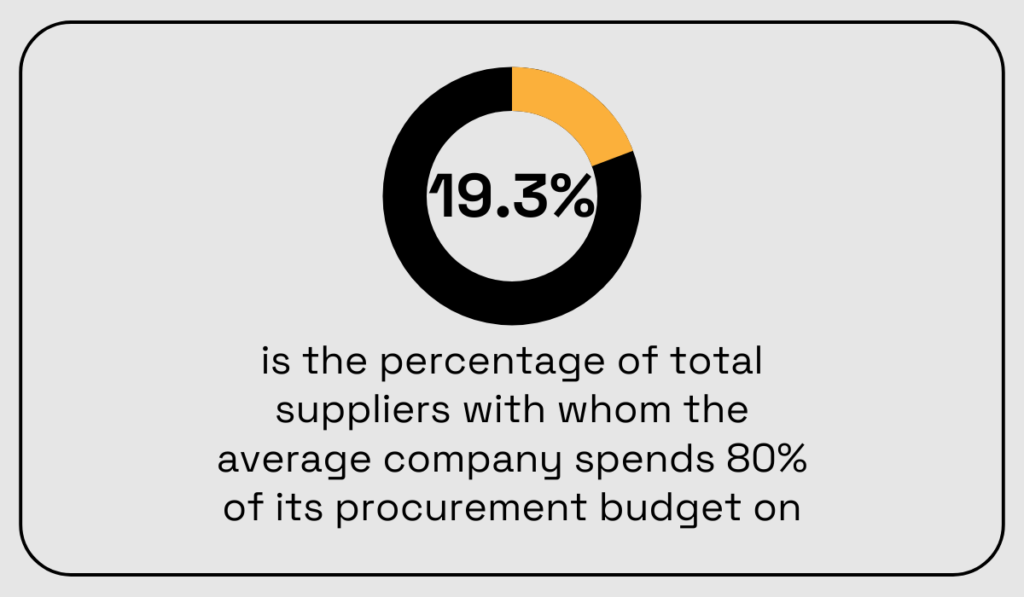

Another valuable resource is Coupa’s business spend management benchmarks.

Their reports offer up-to-date metrics for various procurement activities.

For instance, the 2023 benchmark for spend with primary suppliers provides a snapshot of supplier management practices for savings of top-performing companies.

Illustration: Veridion / Data: Coupa

In the same report, among dozens of other metrics, Coupa also offers other savings-related data, including:

By analyzing this data, you can gauge how your own organization’s practices align with industry best practices.

Benchmarking is not about keeping up with competitors, but about unlocking your full potential for improvement. By understanding where you stand and where you can excel, you’ll transform benchmarking into a powerful tool for driving procurement success.

And that wraps it up!

We hope this article has shed light on how to enhance your savings measurement approach.

Applying these practices will not only help you track your procurement team’s success but also communicate it effectively to stakeholders, reinforcing your strategic importance in the organization.

After all, precise savings data that’s clearly communicated can significantly boost your team’s credibility and drive ongoing improvements.

So, take these insights and turn them into measurable success, showcasing the true value of your procurement efforts.