5 Major Goals of Strategic Procurement

Strategic procurement stands as a collective term for a company-wide, comprehensive, and ongoing process aimed at driving long-term value through procurement activities.

It involves using data analytics tools, advanced technologies, and effective methodologies to analyze various data sources and extract actionable insights.

These insights are then transformed into cost-saving or efficiency-boosting initiatives that align with the company’s business strategy.

This alignment is where the goals of strategic procurement are defined.

In this article, we’re going to explore them in more detail, helping you prioritize, plan, and implement the right strategic procurement initiatives for your organization.

Let’s get started.

One of the goals of strategic procurement is to accelerate the procurement process, i.e., reduce cycle times, meet project deadlines, and respond promptly to changing market conditions or customer demands.

So, how can this broad goal be achieved?

In simple terms, the speed of executing various procurement activities can be effectively increased by implementing a combination of advanced tech tools and efficient management methods.

To illustrate how this can be done, we need to pick one example from a range of the abovementioned procurement timelines.

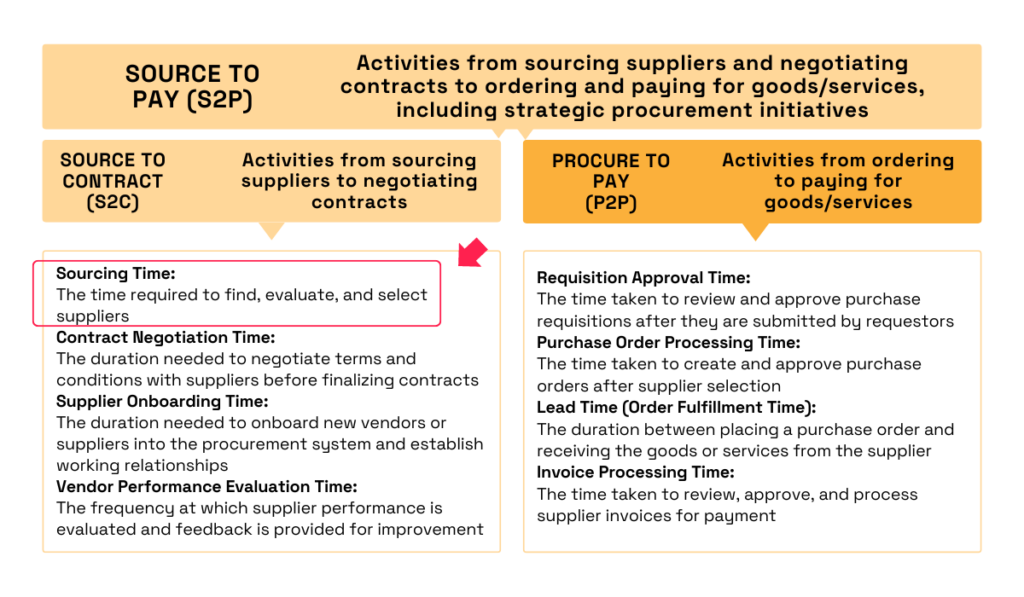

For instance, the below image shows just some of the main cycle times within a comprehensive Source-to-Pay (S2P) process differentiated according to its subcomponents, Source-to-Contract (S2C) and Procure-to-Pay (P2P).

Source: Veridion

As highlighted, we selected supplier sourcing time for our example.

This cycle encompasses the process of discovering potential suppliers, evaluating them against a set of criteria and risk factors, soliciting offers and references, and ultimately selecting the most suitable suppliers.

Depending on the industry, market dynamics, and the complexity of procurement requirements, this is often one of the most time-consuming, yet time-sensitive tasks for procurement teams.

This is particularly true when a company urgently needs to secure a new supplier due to unexpected demand fluctuations or supply chain disruptions.

For example, whether it was a school district looking for new milk suppliers for the soon-starting school year, or hospitals seeking life-saving drugs for their patients, their procurement professionals certainly felt the pressure.

In these and numerous other cases, the speed and efficiency of the supplier sourcing process can significantly impact the organization’s ability to adapt and respond to evolving market conditions.

So, how can a strategic procurement measure of adopting and leveraging technology accelerate the sourcing process?

For starters, supplier sourcing tools like AI-powered big data platforms with advanced search and analytics functions can, as estimated by McKinsey, cut sourcing time by over 90%.

One tool that can help you achieve such profound cycle time reductions is our sourcing enabler, Veridion.

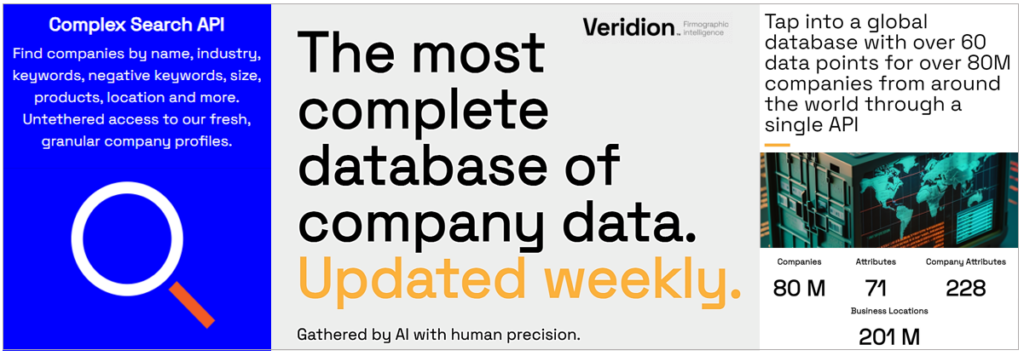

Source: Veridion

Veridion provides you with a global, regularly updated supplier database with over 80 million companies, where over 200 data points are curated by our proprietary, AI-driven algorithms that constantly scour billions of web pages.

Additionally, this database comes with advanced search APIs that are easily integrated with your existing procurement automation tools.

This means your team can filter suppliers according to specific procurement criteria, such as precise product specifications, production capacity, industry, location(s), company size, and more.

Additionally, you can input searches in natural language and use keyword matches or even exclusions to refine the search further.

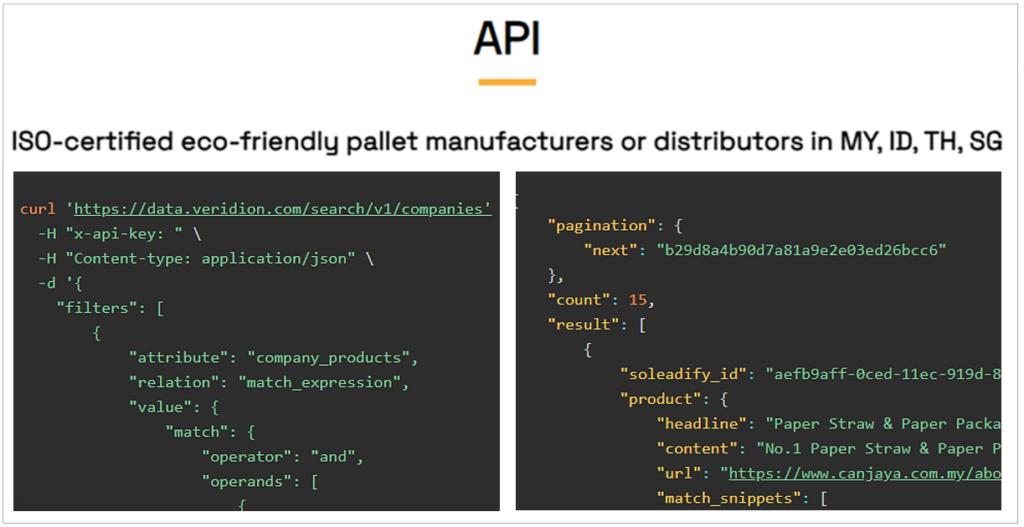

Source: Veridion

As for how a search for a very specific product (chemical compound) by a pharmaceutical company looks, you can see it demonstrated in the below video:

Source: Veridion on YouTube

“A Veridion query typically lasts under five seconds. As you can see, Veridion’s API found 175 companies while competing solutions only found 32 suppliers. Our clients often find such differences after working with our data.”

In our real-life examples of urgent procurement, this would certainly help those organizations minimize the time needed to source new suppliers.

Naturally, digital tools and efficient methodologies can be strategically adopted to streamline other procurement timelines in a similar fashion.

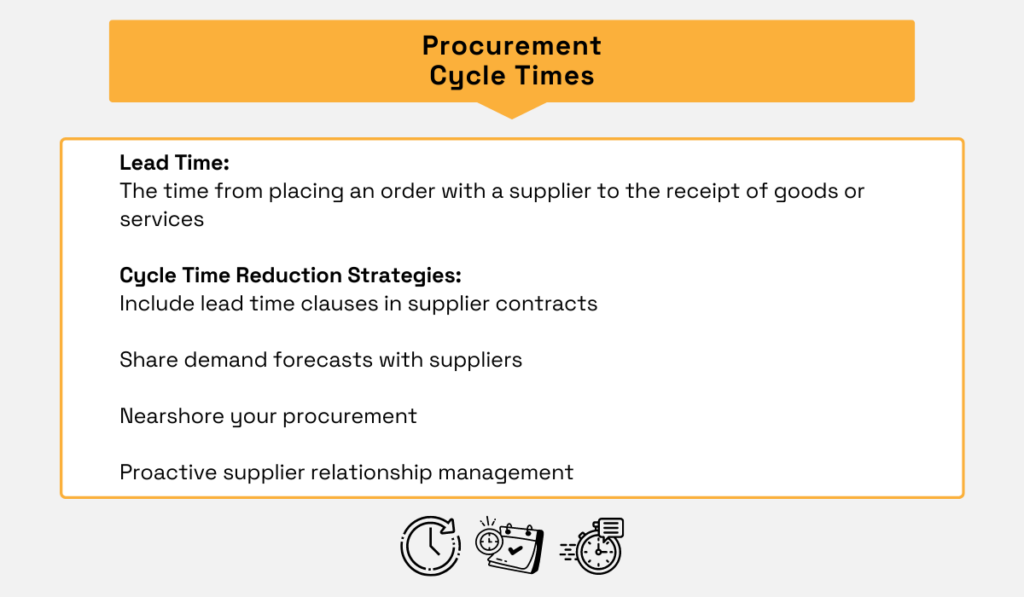

Here’s an overview of some potential strategic measures you can take to increase the execution speed of your procurement cycle times, for instance:

Source: Veridion

To recap, effectively reducing cycle times, meeting project deadlines, and enhancing response-to-change timelines is one of the major goals of strategic procurement.

This goal can be achieved through the thoughtful integration of advanced technologies and efficient management practices, ultimately enhancing your company’s procurement efficiency and responsiveness.

Strategic procurement also aims to encourage creativity and innovation in procurement practices.

This can include exploring new sourcing strategies, adopting advanced technologies like AI, and implementing best practices from other industries.

So, let’s look at a few examples that can shed light on how companies can approach fostering procurement innovation.

For instance, Procter & Gamble (P&G) has long been using an innovation-focused strategy called the “Connect + Develop” initiative, which fosters an open approach to innovation with the goal of achieving higher revenues through external innovations.

Source: P&G

As highlighted, this P&G initiative’s mission is “to anticipate, activate, amplify, and accelerate innovation through external partnerships.”

To achieve this, P&G has established five open innovation maxims that reveal useful principles behind fostering external innovations (from their suppliers and other stakeholders).

Take a look and consider how these tenets could help your company promote procurement innovation:

Illustration: Veridion / Data: SCMR

With this approach, P&G managed to increase its research and development (R&D) productivity by 60% while launching over 100 new products stemming, at least partially, from innovations outside the company.

Of course, innovative sourcing strategies don’t stop here, but these principles show how a company can successfully leverage external innovations to improve its internal processes.

Another example of fostering procurement innovation is adopting new technologies, such as AI tools.

For instance, Walmart has over 100,000 suppliers and struggled to conduct focused negotiations with all of them, so about 20% of suppliers signed “copy/paste” standard contracts, which led to some issues.

To tackle this challenge, Walmart introduced an AI-powered contract negotiations chatbot to streamline the supplier contracting process.

Source: Harvard Business Review

Now, this chatbot is negotiating and closing agreements with 68% of approached suppliers, with the company profiting from more focused, streamlined supplier negotiations.

AI tools are also used by Unilever to help them identify alternative ingredients that will simplify their products, make them more sustainable and cost-efficient, and make their supply chain more resilient to disruptions.

Long story short, whether it’s new sourcing strategies, advanced AI solutions, or best practices from other industries, one major goal of strategic procurement is to encourage collaboration, creativity, and innovation in procurement practices.

We could’ve easily placed cost savings as the first and typically most important goal of strategic procurement.

However, we wanted to highlight that increasing procurement execution speed and fostering innovation ultimately leads to cost savings.

The same applies to enhancing supplier relationships and implementing sustainability-boosting measures, covered a bit later on.

Among this variety of cost-saving initiatives, effective strategies include reducing overhead expenses, optimizing inventory levels, as well as engaging in supplier negotiation and consolidation.

So, let’s look at one such example, namely cutting overhead costs.

As mentioned, companies can significantly cut administrative expenses and improve efficiency by streamlining procurement operations through automation and e-procurement platforms.

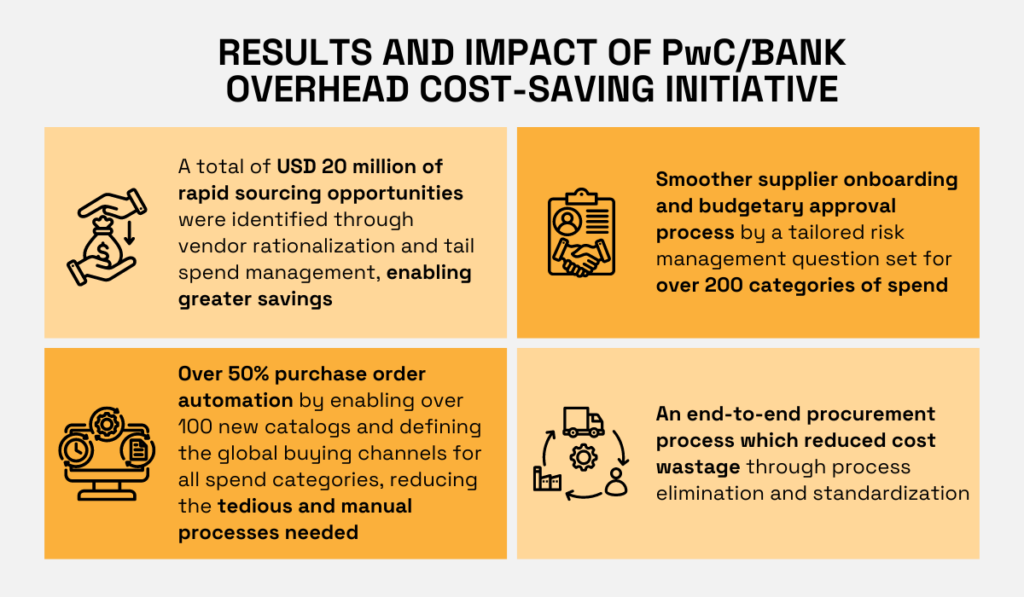

For instance, a PwC case study shows how they helped a global bank streamline their back-office supply chain operations to realize cost savings.

Source: PwC

The bank in question was faced with inefficient and disparate workflows across its procurement categories, company departments, and geographic regions.

This resulted in a number of cost inefficiencies, such as:

PwC helped the client create a new operating model where all procurement data could be found in a centralized database, i.e., a single source of truth.

Among other things, this enabled the bank to provide its procurement team with real-time insights that allowed them to identify cost-saving opportunities.

Additionally, they simplified the supplier onboarding process, created standardized procurement procedures across the company, and automated the requisition and approval process.

You can see the results of this overhead-cutting strategy in the image below.

Illustration: Veridion / Data: PwC

Naturally, there’s a range of other strategic procurement tactics you can employ to reduce costs, such as:

In essence, realizing this goal of strategic procurement requires a data-driven approach that combines technology, comprehensive spend analysis, effective inventory management, and strategic supplier negotiations.

As we’ll discuss next, these savings can be further enhanced by building strategic partnerships with key suppliers.

As indicated, another objective of strategic procurement is the cultivation of strong and mutually beneficial relationships with suppliers.

This involves effective communication, resolving conflicts promptly, and recognizing suppliers’ contributions to the organization’s success.

Although quality relationships with suppliers have always played an important role in driving procurement efficiency, recent supply chain disruptions have underlined just how crucial such relationships can be.

That’s why many companies prioritize building close and effective supplier relationships.

For example, Jabil, a U.S.-based manufacturing company, works closely with Vishay, their supplier of specialized passive components and semiconductors.

Here’s what Vishay’s Senior Vice President Peter Williams has to say about their relationship:

Illustration: Veridion / Data: Jabil

Vishay’s insights into the latest component trends and the most recent technology developments help Jabil assess the current state of the market, plan for the future, and make informed business decisions.

Moreover, this relationship is mutual, as Jabil provides its manufacturing expertise to help Vishay improve operations in its factories.

Simply put, strategic and collaborative partnerships with suppliers don’t only make contract management and supplier performance monitoring easier.

They also increase the chances your orders won’t be put on the backburner in case of shortages or other disruptions.

Additionally, cultivating strong supplier relationships can lead to higher product quality, shorter delivery times, better pricing, and quicker reactions to unexpected supply chain fluctuations.

Given all the above, it’s clear why maintaining quality relationships with suppliers is a critical goal of strategic procurement.

Lastly, strategic procurement aims to align your company’s procurement practices with its sustainability goals.

This can be achieved by sourcing from environmentally responsible suppliers, reducing carbon footprint, minimizing waste generation, and promoting social responsibility throughout the supply chain.

Moreover, with the growing awareness of environmental, ethical, and social issues, companies not addressing these concerns are risking significant negative impacts on their reputation and bottom line.

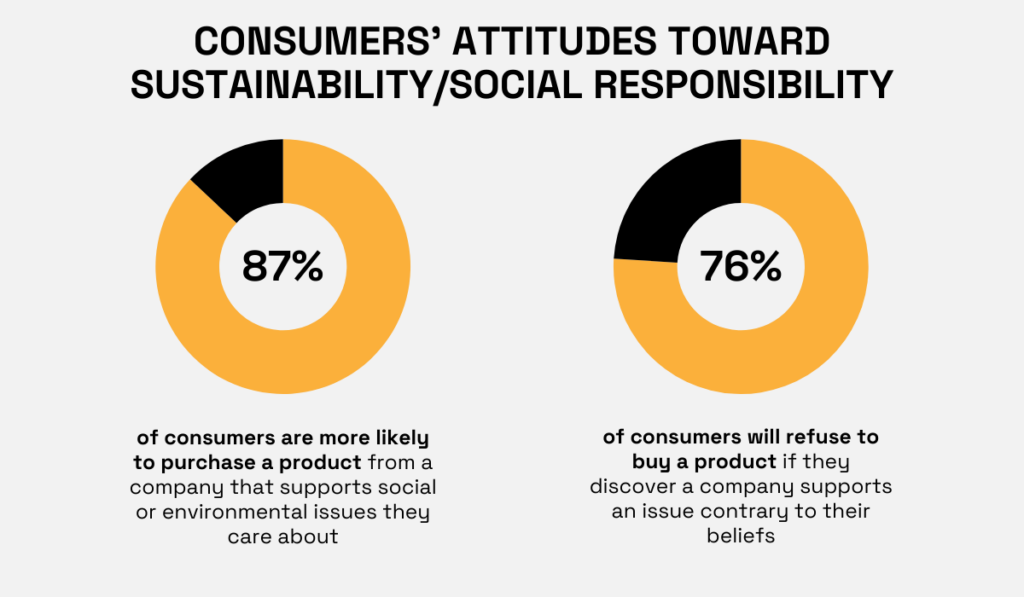

To illustrate the magnitude of these adverse effects, consider the findings from a Cone Communications survey of consumers and their attitudes toward sustainability and social responsibility:

Illustration: Veridion / Data: Cone Communications

These percentages show why companies are investing considerable efforts to meet consumers’ sustainability and ethical expectations.

For instance, at the turn of the century, Nike faced allegations about poor working conditions in their suppliers’ factories.

To tackle these issues, the company redesigned its supplier management tools and, among other measures, introduced the Sourcing & Manufacturing Sustainability Index (SMSI).

This index is used to assess potential suppliers’ factories against unethical labor, health and safety, and environmental protection practices.

By 2020, Nike managed to have all its factories improve their SMSI score to the highest level required.

Source: Harvard.edu

Additionally, Nike introduced sustainability measures across its supply chain by minimizing water usage and waste generation.

This example shows that, from the lens of strategic procurement, companies striving to enhance their reputation and revenues have to ensure that their suppliers understand and comply with their sustainability/ESG/CSR requirements.

In conclusion, by integrating these and other considerations into their procurement operations (primarily supplier sourcing and performance monitoring), companies can ensure their and their consumers’ sustainability expectations are met.

So, with these five goals described, it’s evident that strategic procurement is integral to modern business success, encompassing execution speed, cost savings, and robust supplier relationships.

It’s also clear that strategic procurement requires the use of advanced technologies and efficient management practices that enable companies to streamline procurement operations and respond swiftly to market changes.

Ultimately, these strategies allow companies to optimize their procurement to achieve better business outcomes: increased efficiency, reduced expenses, and a stronger competitive edge.