Supplier Selection: 5 Challenges to Overcome

Finding, evaluating, and selecting the right suppliers that meet company standards for price, quality, and delivery has always been challenging.

However, the interconnected nature of today’s global supply chains has made this process even more complex.

Procurement teams now have access to a much larger pool of potential suppliers, but this also brings more challenges.

Today, we will take you through the five most common challenges in the supplier selection process.

But don’t worry—along will come the tips on how you can overcome them.

It may seem logical that the procurement team knows exactly what to source before searching for suppliers, but this isn’t always true.

Challenges arise when different stakeholders, from top management to operational departments like production, marketing, and engineering, don’t define key procurement requirements clearly.

In other words, when they don’t give clear specifications and instructions to procurement teams.

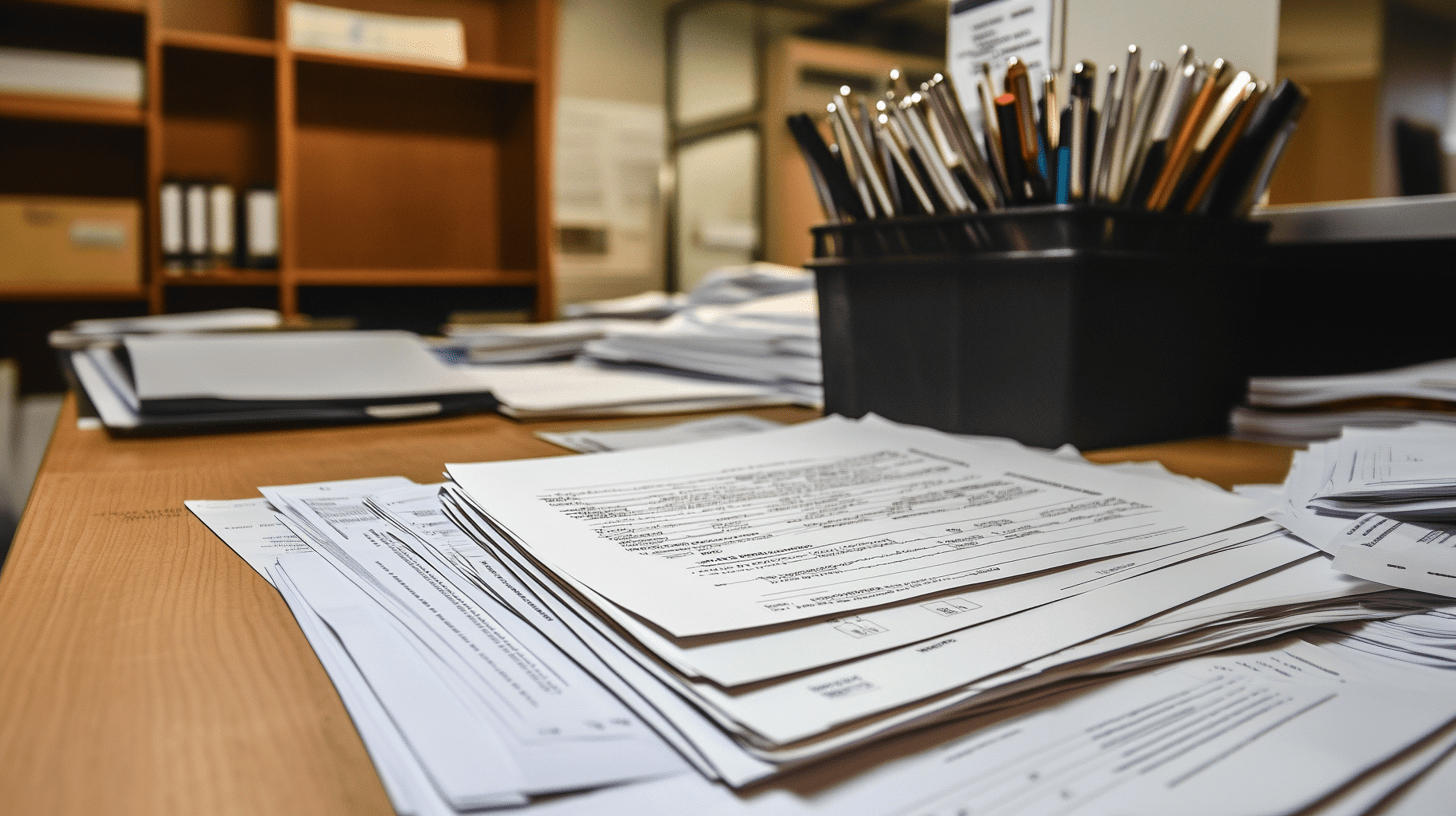

Naturally, one critical element is specifying the exact product or service needed.

However, effective supplier selection involves many more details than just technical specifications.

Here’s a breakdown of the procurement requirements that must be clearly defined for effective supplier selection:

Source: Veridion

Before the procurement team starts searching for potential suppliers, they should be clear on all six requirements.

If they are not, the company can face serious issues.

To illustrate, consider a procurement team sourcing electronic components for their company’s product.

The production department provides detailed technical specifications but fails to specify the need for industry certifications required to sell the final product in certain markets.

The procurement team selects a supplier that meets the technical specifications, and the supplier invests in new equipment to fulfill the orders.

Source: Matric Group

However, after the sample component is delivered, it becomes clear that the supplier lacks the necessary certifications to comply with regulatory standards in key markets.

This leaves the company with two costly options:

Either way, this misstep can result in significant production delays, additional costs, and legal consequences.

This is just one of many examples that shows how important it is to define procurement requirements clearly.

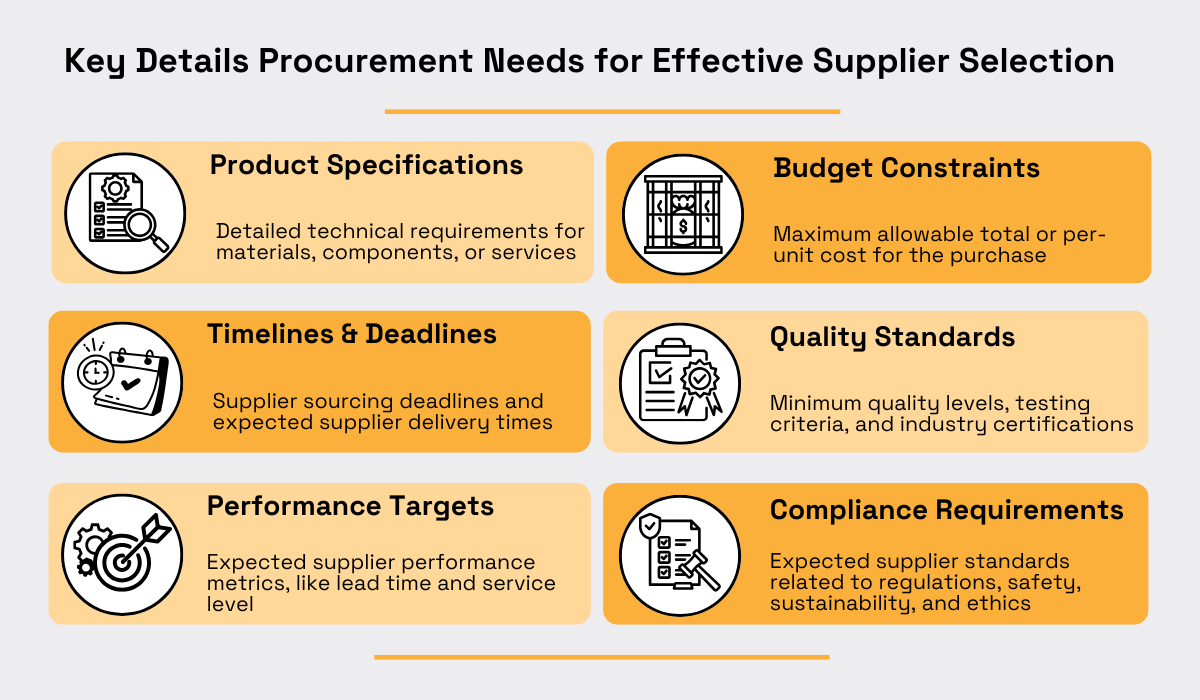

As mentioned, oversights resulting in costly supplier selection mistakes, delays, and unsatisfactory outcomes can happen at any company management level.

Here are a few examples according to the general company hierarchy:

Source: Veridion

Given all these potential risks arising from unclear requirements, it’s easy to see how the supplier selection process can be jeopardized.

So, what can you do to avoid these issues?

Here are some best practices:

With these best practices, the procurement team will know what to look for in a supplier.

Finding the best suppliers requires thorough research and evaluation.

This can be particularly challenging because many products, components, materials, and services are available from multiple suppliers around the world.

As a result, it can feel overwhelming to identify the best fit among many options.

On top of everything, discovering new suppliers and evaluating them based on specific criteria and risk factors is one of the most time-consuming challenges faced by procurement teams.

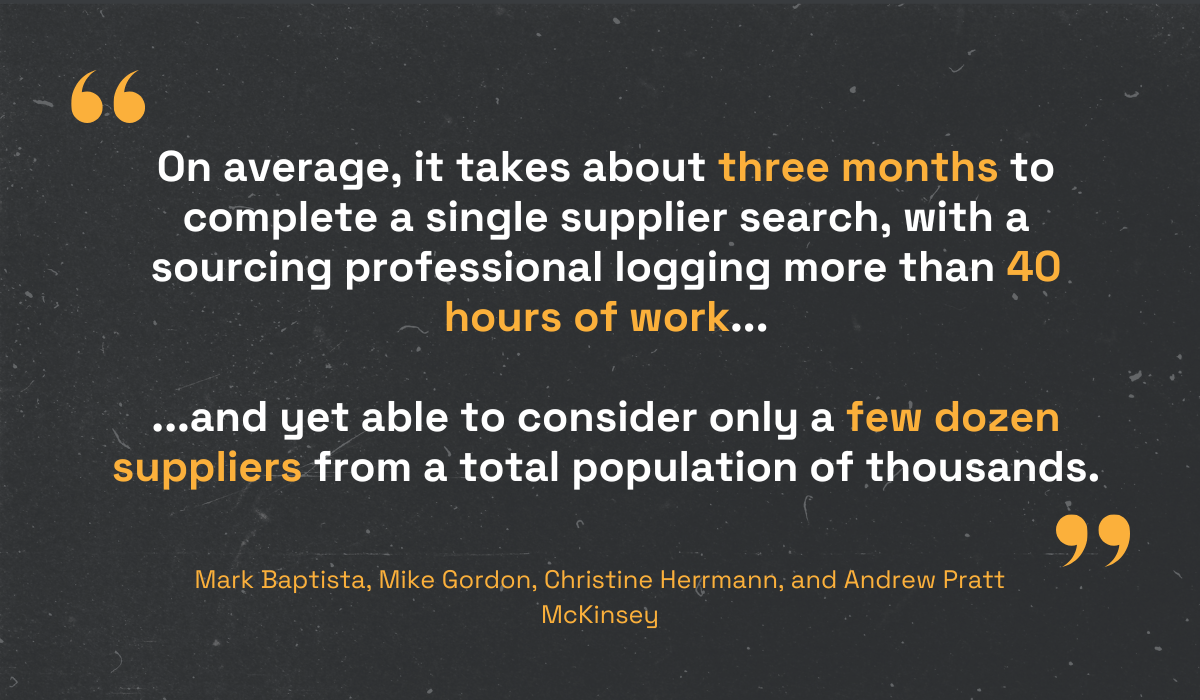

McKinsey’s research confirms this:

Illustration: Veridion / Data: McKinsey

Considering the time and resources required to find suitable suppliers—especially on a global scale—enabling procurement teams to streamline the search process is essential.

This means moving away from manual internet searches, factsheets, and spreadsheets to leverage supplier discovery tools.

According to McKinsey, these tools can cut the time needed to identify the best suppliers by 90% or more.

One such solution is our supplier-sourcing enabler, Veridion.

Veridion gives your organization access to a global, weekly updated database of suppliers.

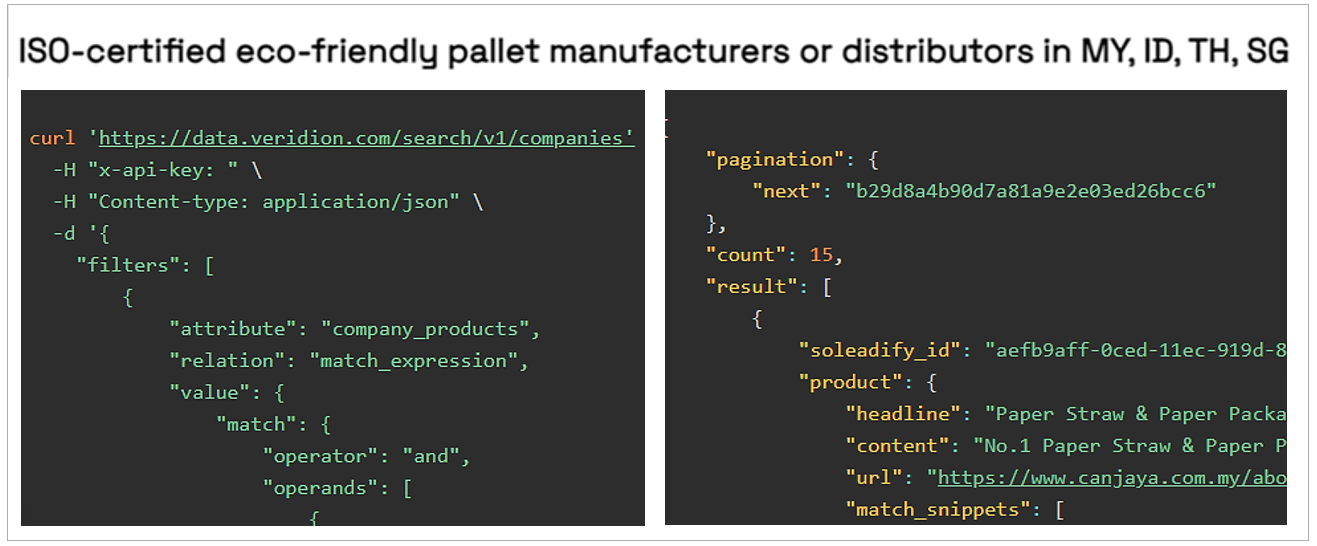

Source: Veridion

Currently, this database covers over 100 million companies across more than 200 million business locations, offering 800 million products and 100 million services.

Veridion’s proprietary AI-driven algorithms continuously refresh this data by scouring the internet, public registries, and commercial databases to gather the latest supplier information.

This is particularly important when discovering suppliers and evaluating them, as relying on outdated data can result in poor selection decisions and increased risks.

Source: Veridion

Using accurate and up to date, your procurement team can further leverage Veridion’s search service to enter a range of specific criteria using natural language.

They can look for suppliers based on criteria such as industry, specific products, facility locations, production capacity, industry certifications, and sustainable or ethical business practices.

Source: Veridion

Since the database search takes only a few seconds, your team can generate a shortlist of prospective suppliers in minutes.

Then, with the shortlist on-screen, procurement professionals can add more criteria, constraints, or other parameters to further refine their search.

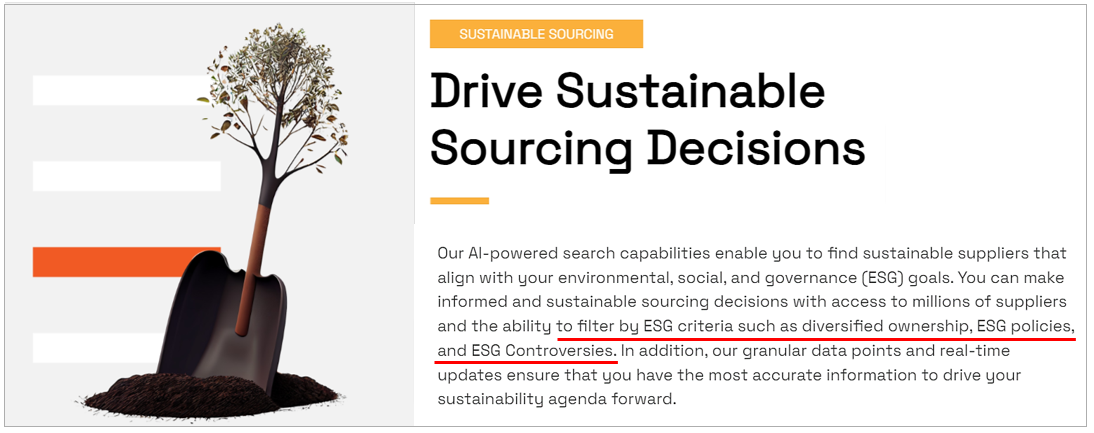

For example, they can leverage Veridion’s data to assess potential suppliers’ financial stability, regulatory compliance, and ESG commitments.

Source: Veridion

All these functionalities represent a giant leap in the team’s efficiency, enabling them to identify more suitable suppliers in significantly less time than through manual methods.

With time and effort saved, they can focus on more strategic tasks, such as engaging with shortlisted suppliers and negotiating favorable terms.

Ultimately, identifying the best suppliers in a global landscape doesn’t have to be challenging.

All you need is the right technology.

As we’ll explore next, these tools are also invaluable when procurement teams face tight deadlines.

Sometimes, procurement teams are pressured to select suppliers quickly, often due to tight project deadlines or urgent operational needs.

When time is limited, there’s a significant risk of rushing up the selection process, which can lead to inadequate vetting of suppliers.

This can result in problems such as poor-quality materials, unreliable deliveries, or even regulatory non-compliance and fines.

In some cases, however, the pressure to quickly secure suppliers for market profit purposes can lead to significant reputational damage.

This happened to Hims & Hers Health, an American telehealth company.

Source: Fast Company

Although the company stated that its supplier vetting process took over a year due to strict due diligence, it seems that rushing to get the product to market may have overlooked critical red flags.

The end result is public scrutiny and financial losses.

While this case represents one of the more severe outcomes that can arise from supplier selection time constraints, it’s far from the only example.

Many procurement teams face various challenges when forced to make quick decisions, which then cause issues down the line.

Along with subpar quality and delivery delays, time constraints can lead to other mistakes such as:

Yes, unrealistic sourcing timelines and management pressures are ideal grounds for oversights that can lead to different types of supplier-related fraud.

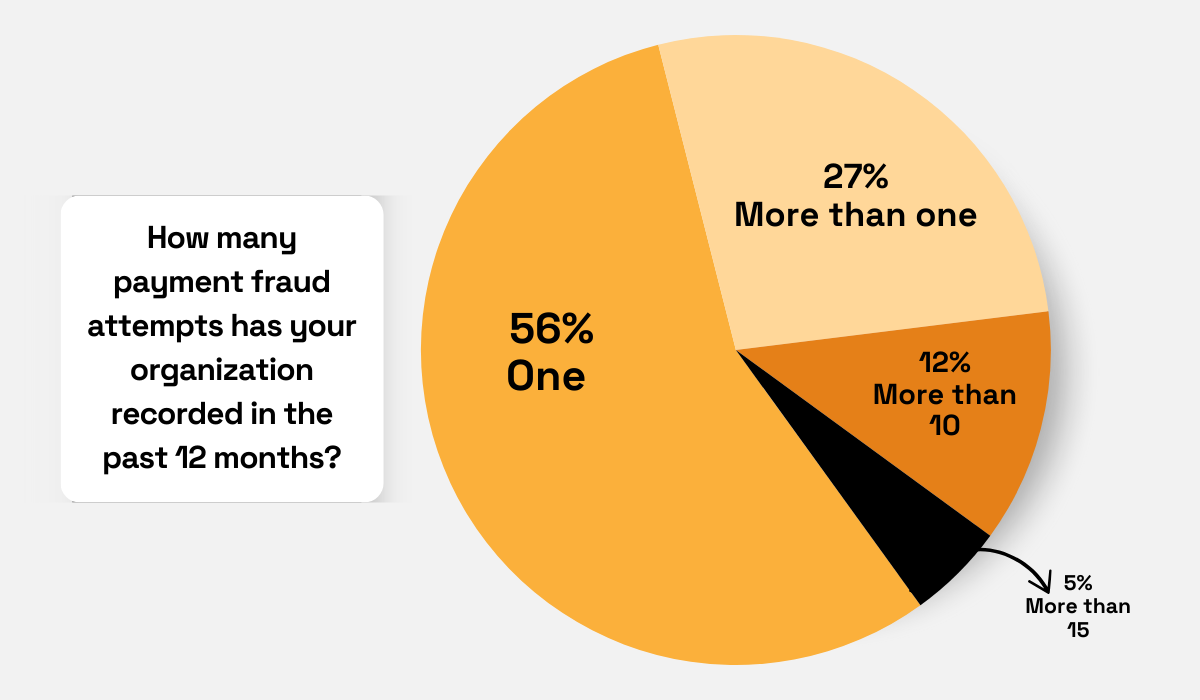

Since rushed supplier selection often leads to inadequate vetting of supplier credentials, this leaves procurement teams vulnerable to issues such as payment fraud.

Consider how the tight deadlines may have contributed to these concerning statistics from TrustPair’s 2023 report:

Illustration: Veridion / Data: TrustPair

So, faced with all these potential pitfalls and increased risks, what can organizations do?

They can implement proper planning, appropriate methodologies, and suitable risk management tools.

When it comes to planning, it’s crucial to establish realistic sourcing timelines early on.

This will ensure the procurement team has enough time to apply thorough supplier vetting criteria.

Beyond that, you can ensure the necessary preconditions for time-pressured supplier selection, such as:

This includes leveraging supplier sourcing tools like Veridion, which not only saves time but also enhances vetting accuracy.

To recap, it’s best to plan ahead and avoid time constraints.

And when tight deadlines do occur, having the right strategies and tools in place will help you navigate them without compromising supplier quality or increasing risks.

Balancing cost and quality is a constant challenge in procurement.

It involves making trade-offs between selecting cost-effective suppliers and ensuring the goods or services meet the required quality standards.

If your procurement team focuses too heavily on minimizing costs, it can lead to poor product quality or service issues.

On the other hand, prioritizing quality without keeping costs in check can strain budgets and negatively impact overall profitability.

Achieving a balance between the two can, therefore, be challenging.

Juliette Ferraro, Marketing Strategist at Thomasnet, warns that focusing only on the best price, although tempting, can hurt you in the long run.

She explains why:

Illustration: Veridion / Data: SupplyChainConnect

Since price alone can’t be the sole deciding factor, balancing cost and quality requires carefully assessing both supplier capabilities and overall financial implications.

Organizations aiming to strike this balance should—as mentioned earlier—start by clearly defining their procurement requirements.

This includes determining which aspects of product quality and supplier performance are critical for smooth operations.

It also involves understanding whether and where cost or quality take precedence in your competitive strategy.

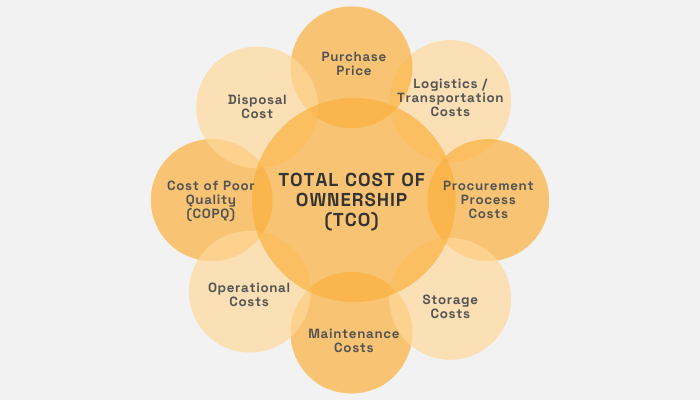

Another important aspect involves evaluating the total cost of ownership (TCO) instead of just the initial purchase price.

As illustrated below, TCO accounts for all ongoing expenses typically incurred while working with a supplier, including storage, maintenance, and costs related to potential quality issues.

Source: Veridion

Another strategic approach involves identifying the risks associated with low-cost options and developing strategies to avoid them (e.g., by not selecting them) or establishing contingencies to mitigate potential issues.

Of course, thorough vetting of suppliers—with realistic timelines—based on their track record, quality assurance systems, and industry certifications is a must.

This is again where updated supplier data, market intelligence, and risk assessments provided by automated sourcing tools become invaluable.

Source: Veridion

In summary, while balancing cost and quality is an ongoing challenge, there are strategies and tools that can make this process more data-driven, leading to better-informed procurement decisions.

Geographic distance and other logistics factors are important when selecting suppliers.

Recent disruptions in global supply chains have made this challenge even more significant.

Nowadays, geographic distance plays a critical role in procurement decision-making.

It affects not only logistics and lead times but also the potential risks associated with transportation and supply chain disruptions.

For instance, choosing suppliers that are far away can lead to longer delivery times, increased shipping costs, and potential supply route breakdowns due to geopolitical conflicts or accidents.

Source: PEMP

On the other hand, local (onshore or nearshore) suppliers can offer quicker turnaround times.

However, they may be more expensive or have limitations in capacity or specific offerings.

Just like with cost and quality, procurement teams must balance these trade-offs.

So, what can you do to improve your supplier selection decisions based on location?

Omer Abdullah, co-founder of market intelligence provider The Smart Cube, recommends adopting an intelligence-driven approach to enhance your decision-making.

As he explains, this approach involves:

Illustration: Veridion / Data: SCMR

His advice highlights the importance of staying informed about geopolitical developments that may impact suppliers in distant locations.

It also underlines the value of diversifying your supplier base to reduce supply chain dependence on any single region.

Of course, thorough risk assessments related to geographic location should include considering factors such as:

Overall, location-specific risks in supplier selection can be mitigated by considering the right factors and ensuring your team has access to up-to-date market intelligence.

It’s evident that effective supplier selection requires a careful balance between multiple factors, from clear procurement requirements to considering logistics challenges.

Despite many potential pitfalls, strategic planning and data-driven tools can enable procurement teams to navigate them and make well-informed decisions successfully.

Doing so can help your company mitigate risks, optimize supplier relationships, and ultimately enhance the efficiency and reliability of your supply chain.

With the right tools, supplier selection doesn’t have to be so challenging, after all!