7 Key Steps of Successful Supplier Sourcing

Key Takeaways:

Supplier sourcing is the heart of procurement success.

It has significant influence over both financial performance and operational efficiency.

It is no surprise that, as procurement professionals, you’re constantly seeking ways to optimize your sourcing strategies and build stronger supplier relationships.

This article is a helpful guide for doing just that.

In the following steps, we will outline the full process for successful supplier sourcing, from identifying and evaluating, to selecting the best suppliers for your needs.

So, if you want to improve your sourcing strategy, here are all the tools and insights to get you started.

You can’t go blindly into supplier sourcing without first assessing your procurement needs.

This means taking a close look at the specific products, services, and materials you require.

Why?

Well, because without understanding your needs clearly, you risk wasting time and resources on suppliers who simply cannot meet your demands.

The specific products or services you’ll need and their quantity are just one aspect to assess.

You must also consider the quality standards, delivery timelines, and other specific requirements.

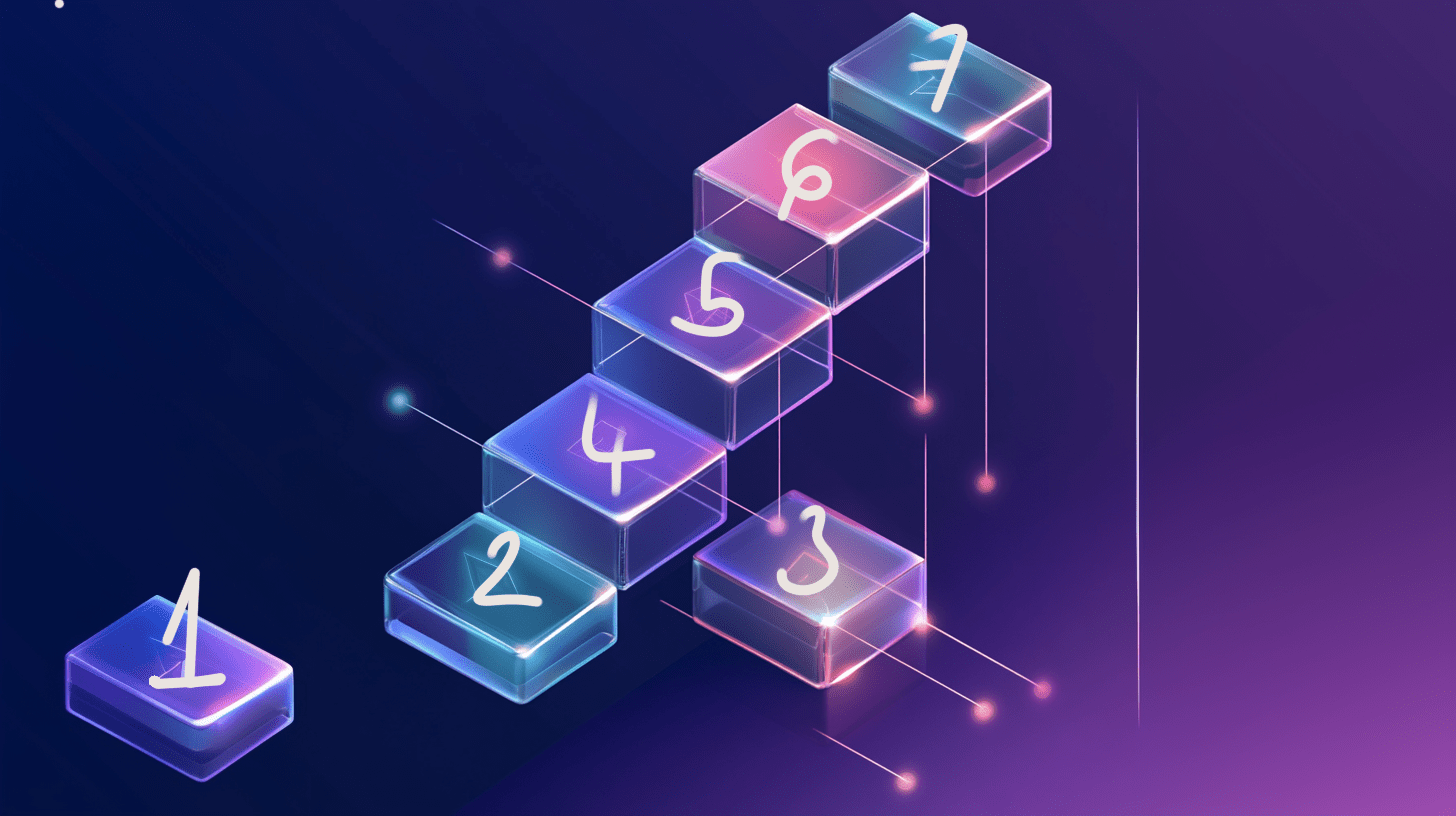

The image below outlines the three types of needs specifications you’ll want to create:

Source: Veridion

Technical specifications include size, weight, materials used, or specific technical standards that the products or services you’re procuring must meet.

On the other hand, functional specifications focus on how the product or service should perform, including speed, efficiency, durability, or compatibility with existing systems.

Finally, there’s the procurement budget you want to think about.

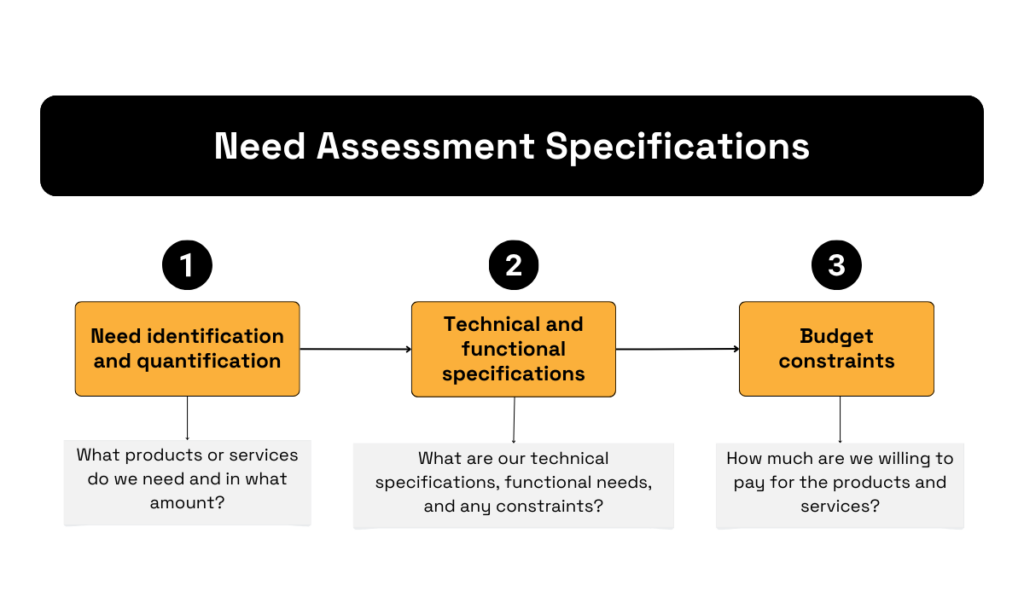

One of procurement’s most important functions is finding ways to keep costs down.

And statistics back this up.

The 2022 Global CPO survey by EY reveals that cost reduction is a top priority for 80% of CPOs.

Illustration: Veridion / Data: EY

That’s why it’s essential to estimate the cost of the required goods or services as accurately as possible.

This includes not only the direct cost of the items themselves but also the costs associated with the sourcing process, like RFP development, supplier evaluation, and negotiation and contracting.

A solid foundation in this step is essential for later success during sourcing.

Next, the procurement team should develop a comprehensive framework for evaluating and selecting suppliers.

This framework helps you define your priorities, standardizes your sourcing approach, and ultimately leads to better sourcing decisions.

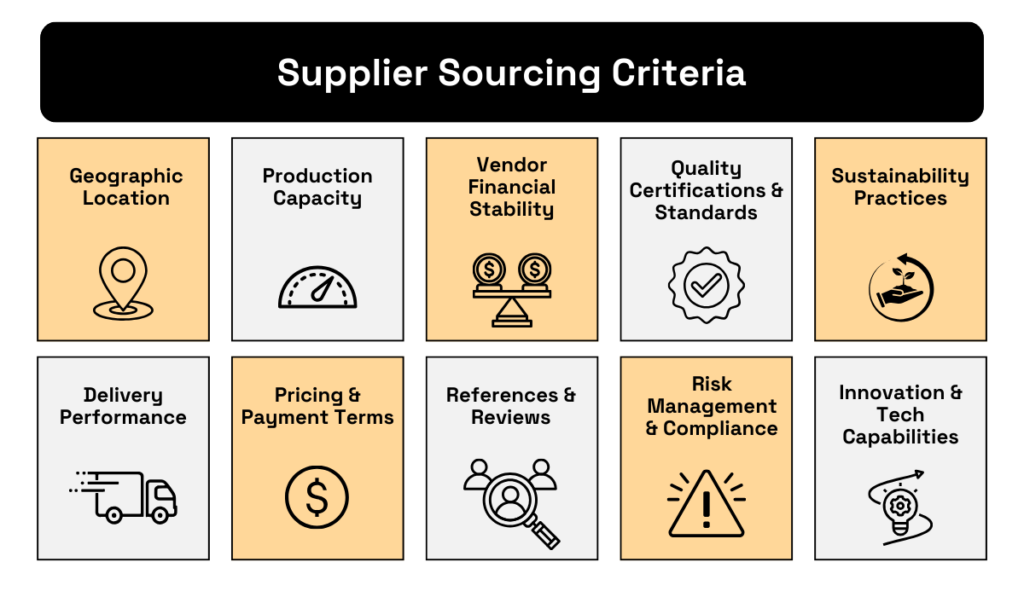

The first step towards creating a sourcing framework is to define your supplier selection criteria.

Below are some of the most commonly used criteria:

Source: Veridion

Naturally, the quality of the goods or services, delivery speed and consistency, and the level of service should be key priorities.

However, each organization should also evaluate its own specific criteria.

Think long-term, taking into account potential supply chain challenges that could arise in the future.

Just remember the challenges that Apple faced in 2021, when chip shortages disrupted the iPhone 13 production.

Source: Bloomberg

While situations like this one are sometimes hard to predict, it’s important to try to mitigate them with a well-thought-out sourcing framework.

This might involve diversifying your supplier base, building strong relationships with key suppliers, or incorporating flexibility into your contracts.

During this step, you’ll also need to define the sourcing process itself.

This includes establishing clear timelines, outlining stakeholder involvement, and setting decision-making protocols.

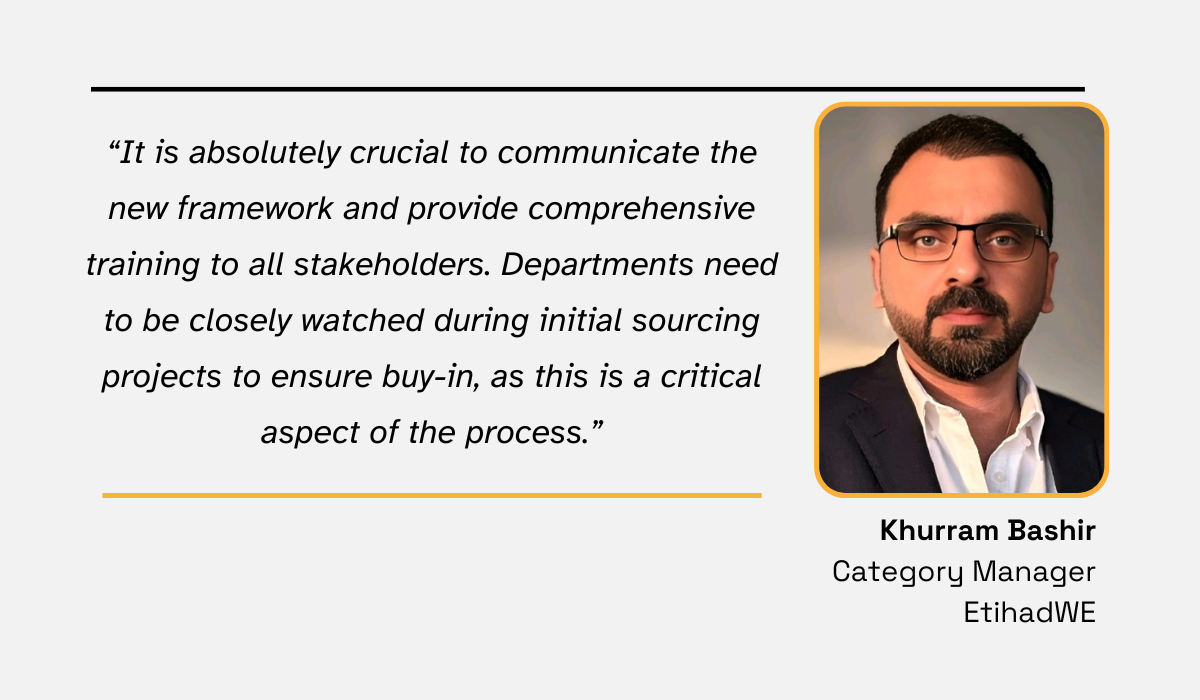

According to Category Manager Khuram Bashir, communicating and getting buy-in from stakeholders in this step is crucial:

Illustration: Veridion / Quote: LinkedIn

When everyone is on the same page and understands the objectives and criteria, your sourcing process is much more likely to be successful.

So, take the time to carefully create and communicate your framework and get input from all stakeholders along the way.

Now that you have a solid sourcing framework in place, it’s time to start searching for potential suppliers.

Using your framework as a reference, the procurement team can explore various sources to identify potential vendors.

Some of these sources are listed below:

Source: Veridion

Visiting trade shows or using referrals from trusted sources is a great way to connect directly with reputable vendors.

However, in this digital age, analyzing more data is often better.

Online directories and search engines provide access to a vast pool of potential suppliers.

Plus, you can easily compare offerings, specializations, and even customer reviews.

However, sifting through countless websites and online profiles to find the right suppliers can be time-consuming and inefficient.

That’s where supplier discovery software solutions like Veridion come in.

Veridion is our AI-powered supplier sourcing enablement system boasting a database of 100+ million companies.

And it constantly gets bigger as it scraps the Internet for always fresh supplier data.

But don’t worry—searching this database couldn’t be simpler.

On one side, we have our data discovery platform, in which you simply input your supplier criteria, and you get a list of potential suppliers in seconds.

You can then refine your search and dive deeper into supplier specifics.

Source: Veridion on YouTube

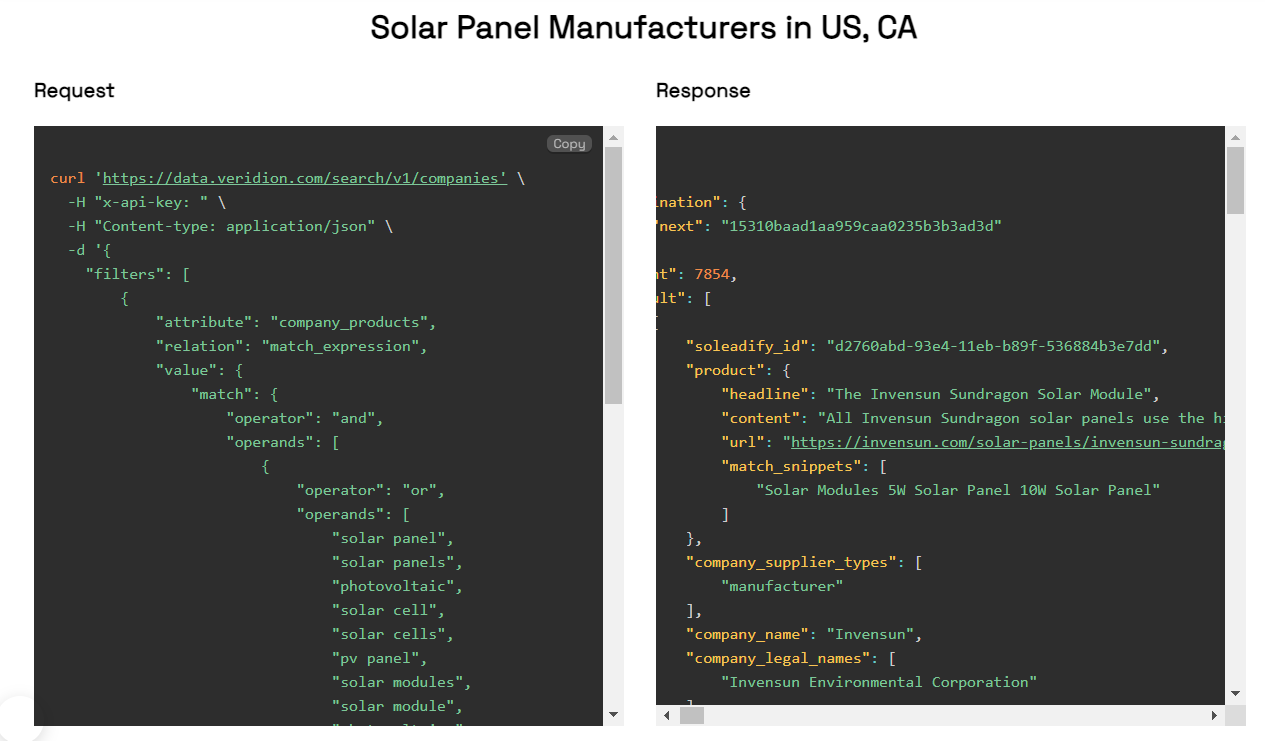

On the other hand, we have Search APIs that can easily integrate with your other systems.

Source: Veridion

By simply entering the criteria you want potential suppliers to meet, ranging from detailed product specifications to facility locations and production capacities, you can get detailed, granular company profiles in moments.

Conversely, our Match & Enrich service can enrich your current supplier lists with fresh data gathered through other methods.

After you find your potential suppliers, you should send out requests for information (RFIs) to them.

With these questionnaires, you can gather detailed information about the vendor’s capabilities, experience, and compliance with industry standards before diving deeper into the sourcing process.

The ultimate goal with all of this research is to identify a pool of qualified suppliers who can fulfill the needs you established in the first step and meet the criteria outlined in your sourcing framework.

With a preliminary list of potential suppliers in hand, it’s time to move into the sourcing process.

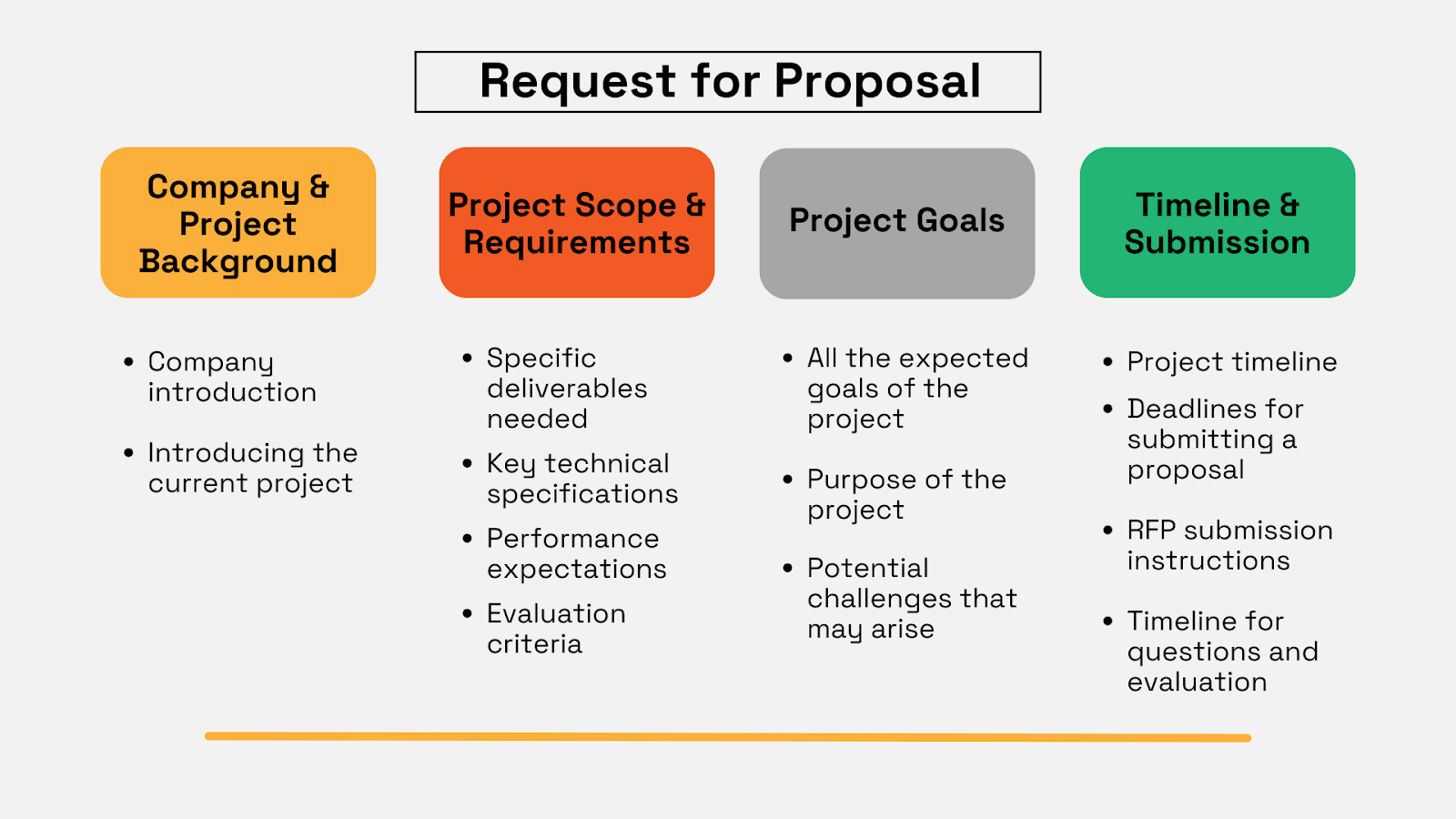

This is where you start engaging directly with suppliers by issuing requests for proposals (RFPs).

These documents are formal invitations for suppliers to submit detailed proposals outlining how they can meet your specific needs.

RFPs must contain some important elements, as shown below:

Source: Veridion

In general, you want to clearly describe your project scope, goals, and requirements to potential suppliers.

And, you want to give vendors a chance to showcase their capabilities, propose solutions, and provide detailed pricing information.

As Marjin Overvest, founder of Procurement Tactics, explains, RFPs are an essential document for smart procurement:

Illustration: Veridion / Quote: Procurement Tactics

RFPs bring structure and clarity and allow you to compare “apples to apples” by ensuring all suppliers respond to the same set of requirements.

Once you’ve sent out RFPs and started receiving proposals from suppliers, you can begin compiling that data and sorting it out.

This often involves creating a comparison table to evaluate suppliers across various criteria.

The table below shows a simplified version of how this can look like:

| Supplier A | Supplier B | Supplier C | |

| Pricing | $10,000 | $12,000 | $8,500 |

| Experience | 5 years | 10 years | 2 years |

| Customer Support | 24/7 phone and email | Email-only | 8-hour phone support |

| Technical Expertise | High-rise building supply specialization | Road and bridge industry expertise | Focus on eco-friendly and sustainable materials |

| Scalability | Can handle large-scale projects | Best for small to medium projects | Scalable with limitations |

| References | Provided 3 client references | Provided 5 client references | Provided 1 client reference |

Overall, issuing RFPs and systematically evaluating supplier proposals are crucial steps in the sourcing process.

This structured approach ensures objectivity and helps you better compare your list of suppliers.

Through an effective sourcing process, you should hopefully end up with a shortlist of suppliers that meet your criteria and have submitted compelling proposals.

Now, it’s time for the procurement team to engage in negotiations to finalize the deal.

This involves focusing on key aspects like pricing and payment terms, delivery schedules, minimum order quantities, service level agreements, and more.

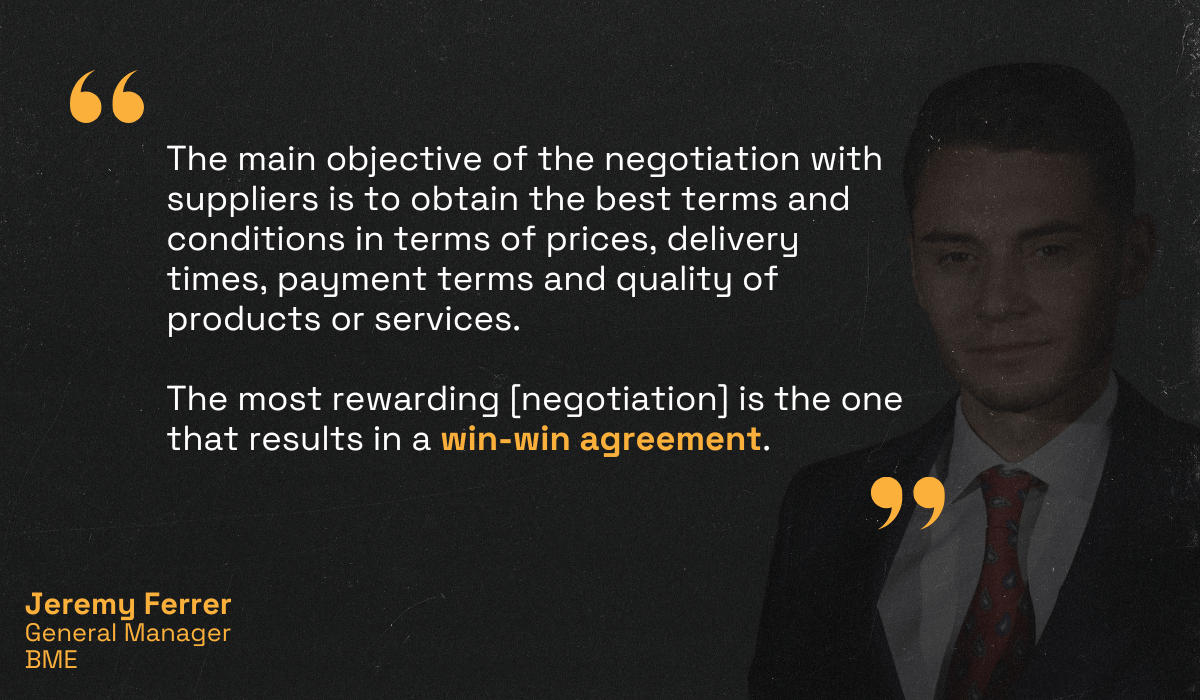

It’s worth mentioning that negotiating is a nuanced part of the sourcing process, as there are several approaches or styles you can take.

Source: Veridion

Depending on a company’s leverage and specific situation, you might choose a competitive strategy.

Here, you want to get the most favorable conditions for your organization, potentially at the expense of the supplier.

This can be a good choice when you have strong leverage, such as high-volume orders or readily available alternative suppliers.

But, as the general manager of Buy Made Easy, Jeremy Ferrer, explains, the most favorable outcome is a win-win:

Illustration: Veridion / Quote: BME

After all, while you want the best terms for your company, picking a problem-solving and collaborative negotiation style can be highly beneficial as this approach focuses on building a long-term relationship with the supplier and finding solutions that benefit both parties.

Some potential benefits of collaborating with suppliers include:

Overall, with the right balance of collaboration and focusing on your company’s needs, you can create a more successful and mutually beneficial partnership.

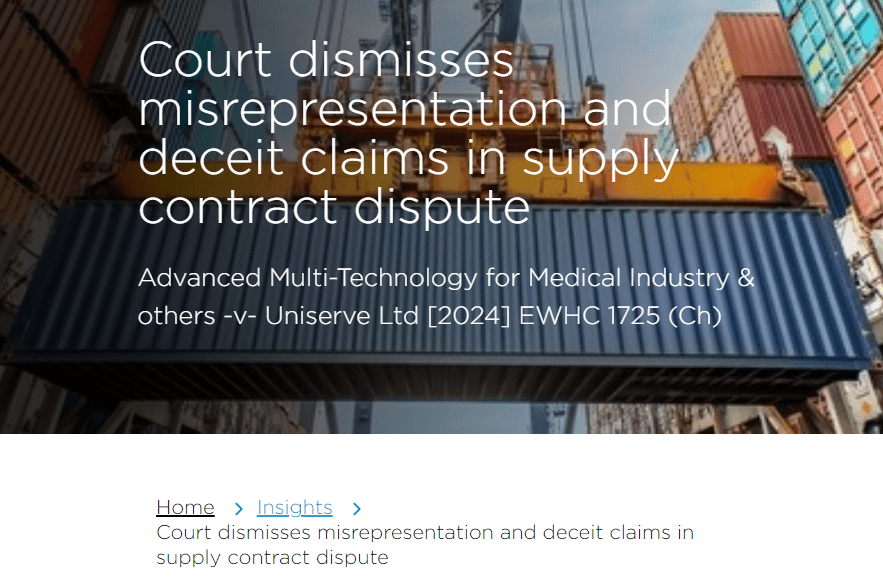

After successful negotiations, you’ve reached the second-to-last step in the supplier sourcing process: signing the contracts.

Depending on the complexity of your needs and the nature of the supplier relationship, this might involve several different agreements, like the following:

If we take a generic contract with a supplier for services or goods, there are certain elements you’ll want to include:

Source: Veridion

These contracts need to be carefully put together and checked by your legal team.

Everything needs to be double-checked, especially crucial aspects like the scope of services, payment and pricing structure, and performance agreements such as delivery dates and product quality.

When dealing with more complex contracts with multiple involved parties, being meticulous here is even more important.

You want to avoid situations like the supply contract dispute illustrated in the article below, which involved agreements relating to the procurement of personal protection equipment (PPE) during the COVID-19 pandemic.

Source: Hill Dickinson

In this case, information was handled through multiple parties, which led to a misunderstanding or miscommunication about the quantity of masks that could be supplied.

This caused a dispute over who was at fault—whether the supplier or the buyer breached the contract, and if the buyer had the right to terminate the agreement.

Although the court eventually ruled in favor of the supplier, the legal process took four years and was both tedious and expensive.

To avoid issues like this, it’s essential to have strong, clear, and concise contracts that all parties fully understand.

So, take the time to create well-defined contracts, and you will minimize problems down the line.

To make sure contracts are upheld and suppliers adhere to the standards you’ve set, you need to continuously monitor their performance.

This ongoing assessment helps you identify any potential issues early on, track progress, and ensure that your suppliers are meeting their obligations.

Most commonly, assessing suppliers is done through already established key performance indicators (KPIs).

They should be specific, measurable, agreed upon and included in the contracts.

Some of these supplier performance metrics are illustrated below:

Source: Veridion

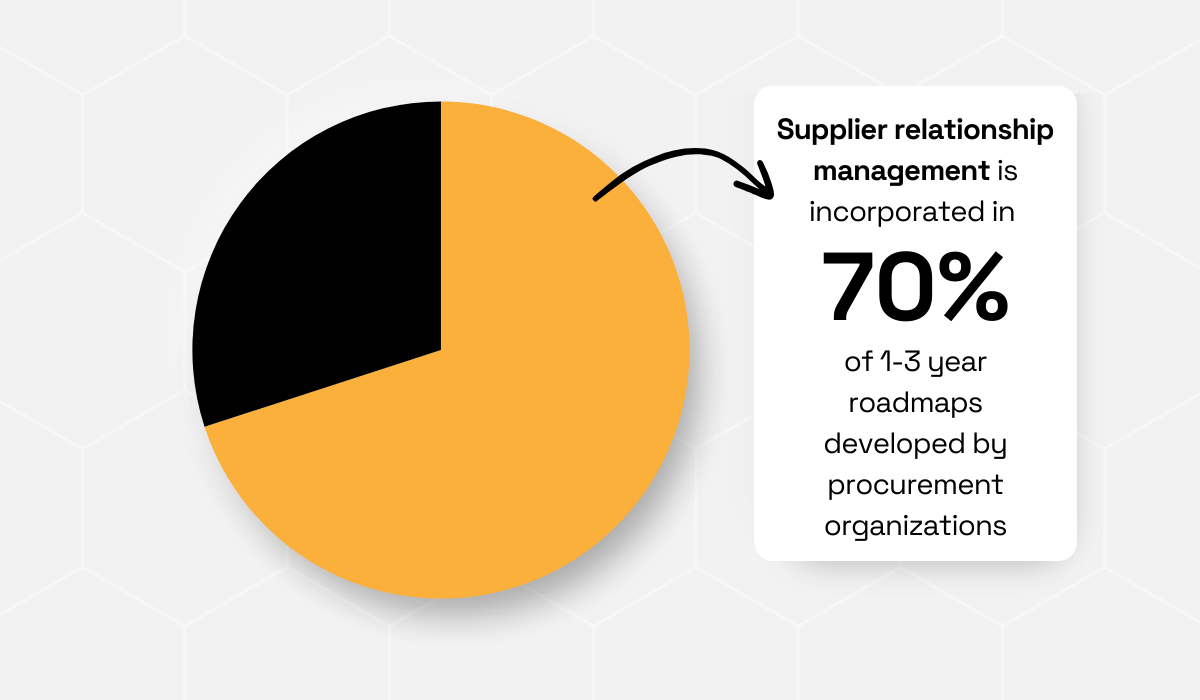

Now, it’s important to mention that metric-driven supplier performance management (SPM) is just one aspect of monitoring and interacting with suppliers.

The other is supplier relationship management (SRM), with the differences between the two outlined below:

| Supplier Performance Management (SPM) | Supplier Relationship Management (SRM) | |

| Focus | Monitoring and evaluating supplier performance against predefined metrics. | Building and nurturing collaborative relationships with strategic suppliers. |

| Objective | Ensure suppliers meet contractual obligations and performance standards. | Create mutual value and achieve shared goals through collaboration. |

| Scope | Tactical, focused on specific deliverables and KPIs. | Strategic, encompassing the entire supplier relationship lifecycle. |

| Metrics | Quantitative (e.g., on-time delivery, quality ratings, cost). | Both quantitative and qualitative (e.g., trust, communication, innovation). |

| Time Horizon | Short to medium term. | Long term. |

So, while SPM is all about efficient execution, ensuring production schedules, effectively managing inventory, and reducing disruptions, SRM takes a more long-term view.

It requires collaboration in planning, fostering innovation, and creating value together.

Organizations invest in building strong partnerships with strategic suppliers, knowing these relationships can drive their success.

In fact, according to KPMG’s 2023 Global Procurement Survey, most organizations have SRM initiatives in their 1-3 year procurement roadmaps.

Illustration: Veridion / Data: KPMG

The same survey reported that focusing on SRM boosted performance by over 10% by improving on-time delivery and service levels.

Additionally, SRM reduced supply risk, and enhanced product and service quality.

So, what’s the best approach for monitoring and measuring supplier performance?

A combination of both SPM and SRM.

This way, you ensure supplier obligations and standards are consistently met while also fostering long-term success through strategic partnerships.

There you have it, seven key steps for successful supplier sourcing.

From conducting thorough research and setting clear supplier criteria to negotiation tips and the importance of supplier monitoring, we have covered it all.

By following this practical guide and adapting each step to your organization’s specific needs, you can establish a more robust and effective sourcing strategy.

This, in turn, will contribute to long-term value creation and enhance your overall procurement efforts.

So, what’s the next step?

Well, it’s time to put this knowledge into action and optimize your sourcing process!