The Full Guide to Procurement KPIs

Procurement isn’t just about placing an order, getting the product, and paying suppliers.

One essential part of the procurement role is tracking key performance indicators, or simply KPIs.

Why?

Let’s just say that by tracking these metrics, you can help both your procurement department and your entire organization.

How?

We will show you throughout this article.

We will also explain what procurement KPIs are in detail, what categories of KPIs there are, why you should track and measure them, and finally, which tools can assist you to do it most efficiently.

So, join us as we explore procurement KPIs in depth.

Procurement KPIs are highly beneficial to track because they measure how effectively you manage your procurement process.

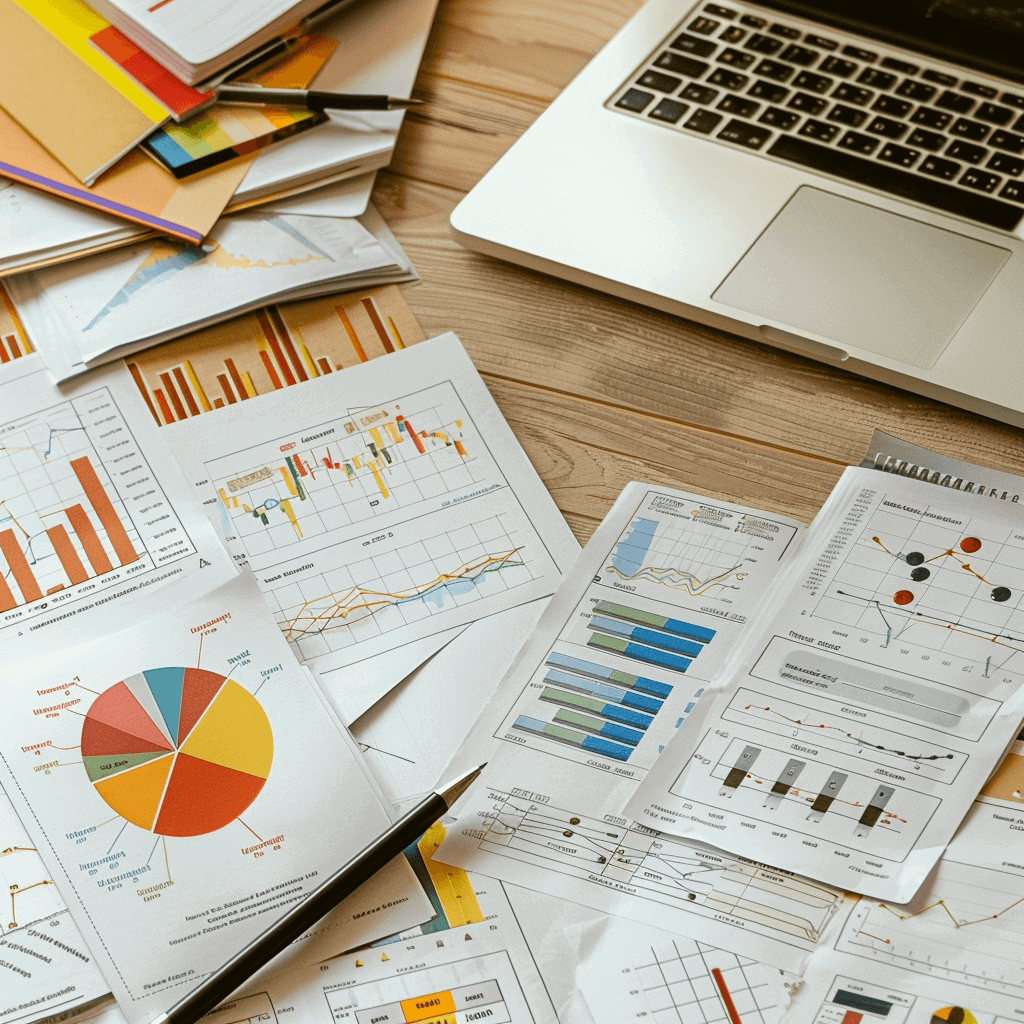

Think of them as tools that assess each step of the procurement cycle and the performance of everyone involved.

Procurement involves several steps, as shown in the image below.

Source: Veridion

Procurement KPIs measure how well each of these steps is handled, as well as the efficiency of key people handling them—namely, your procurement team and suppliers.

For example, tracking the right KPIs will show whether:

These KPIs will also highlight inefficiencies, bottlenecks, and areas for improvement in the procurement process.

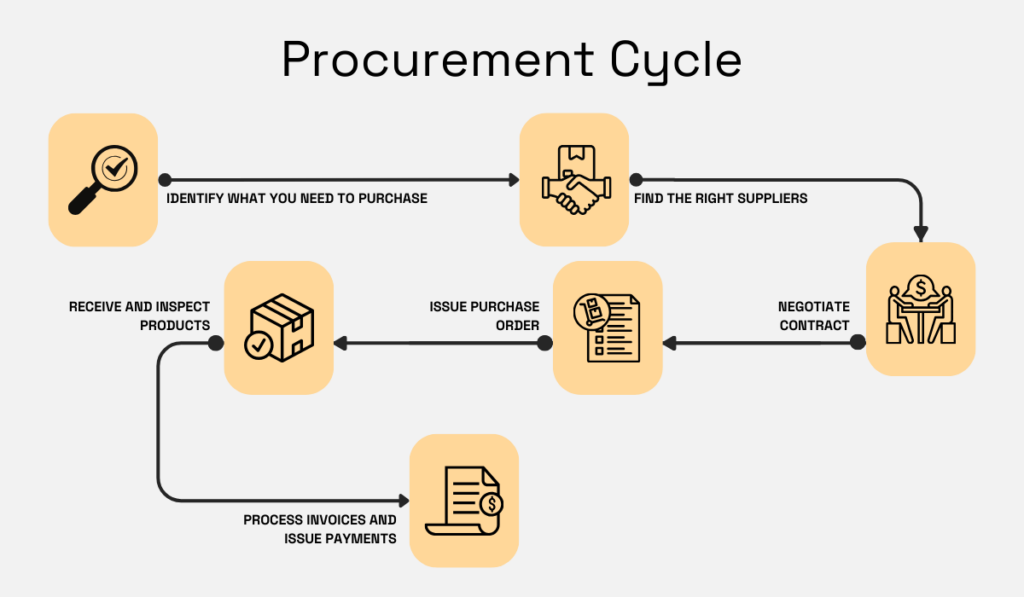

And as Jeetendra Kasar, Business Head for Pricol Asia and an expert in global supply chain management, points out, without measuring procurement KPIs, you wouldn’t be able to realize inefficiencies in time:

Illustration: Veridion / Quote: LinkedIn

In other words, regularly tracking procurement KPIs will help you quickly identify problems, whether they stem from suppliers delivering defective products or from internal issues, such as increased maverick spending because your team is not sourcing from agreed-upon suppliers.

All these factors can be tracked through the right procurement KPIs that fall into various categories, which we will explain later.

When regularly monitored, these KPIs give a true picture of your entire procurement process and help you make data-driven decisions to optimize procurement and deliver value to your organization.

Let’s dive into these reasons in more detail.

So, why bother collecting all that procurement data and crunching numbers (yes, some of these KPIs involve math)?

Here are three simple but powerful reasons.

Let’s face it: you need to know how well your procurement processes are functioning and how your suppliers are performing.

Why?

Because having data on these crucial aspects allows you to assess procurement performance and make improvements.

For example, by tracking supplier-related KPIs like delivery times and product quality, you can see if your suppliers are dependable and if they’re delivering goods on time and up to standard.

If you notice consistent issues—like late deliveries or faulty products—having insight into those KPIs can help you address them more promptly and discuss with suppliers to improve, as Ronanki Ravi, Quality Manager at GRI Renewable Industries, suggests:

Illustration: Veridion / Quote: LinkedIn

But if that doesn’t happen, you can decide to find more reliable suppliers to keep your operations smooth.

On the other hand, monitoring KPIs like purchase order cycle time can reveal process inefficiencies—whether it’s internal delays in approvals or sluggish supplier responses.

Identifying these bottlenecks enables you to streamline processes, such as automating approvals or sourcing from faster suppliers.

And let’s not forget this simple truth: sometimes you just want to give your team a pat on the back and say, “Hey team, we’re killing it!”

But you can’t do that without measuring how well you’re actually performing, right?

Measuring KPIs works wonders for your risk mitigation efforts.

Specific KPIs, like supplier financial health and compliance rates, but even their delivery times, help you identify and mitigate supplier-related risks.

And when you know the risks ahead, you can prevent them or devise strategies to minimize them.

Moreover, keeping an eye on stock levels and lead times lets you stay ahead of supply chain disruptions and avoid running out of essential items.

Understanding how long it takes for orders to arrive—from the moment you place them to when they’re delivered—helps you time your orders just right to prevent shortages and keep things running smoothly.

But it’s not only about supplier-related metrics.

To better manage your procurement risks, you can also measure different compliance KPIs.

For example, if you run a manufacturing company that produces electronics, there are strict regulations about the disposal of electronic waste to protect the environment that you must follow.

One is properly recycling and disposing of electronic components according to environmental laws.

Sophia Fahlen, the Head of IU Ericsson Connected Recycling, highlights the importance of transparency in waste management, as it helps organizations comply with regulations.

Illustration: Veridion / Quote: Sustainability Magazine

Now, if you don’t track compliance with these regulations—like how well you’re managing this electronic waste—you could face legal risks, hefty fines, and penalties.

In essence, tracking compliance KPIs helps you stay on the right side of the law, avoid legal issues, and protect your organization from potential penalties that could arise from non-compliance.

Another good reason to track procurement KPIs is to make sure your procurement efforts are in sync with your organization’s big-picture goals.

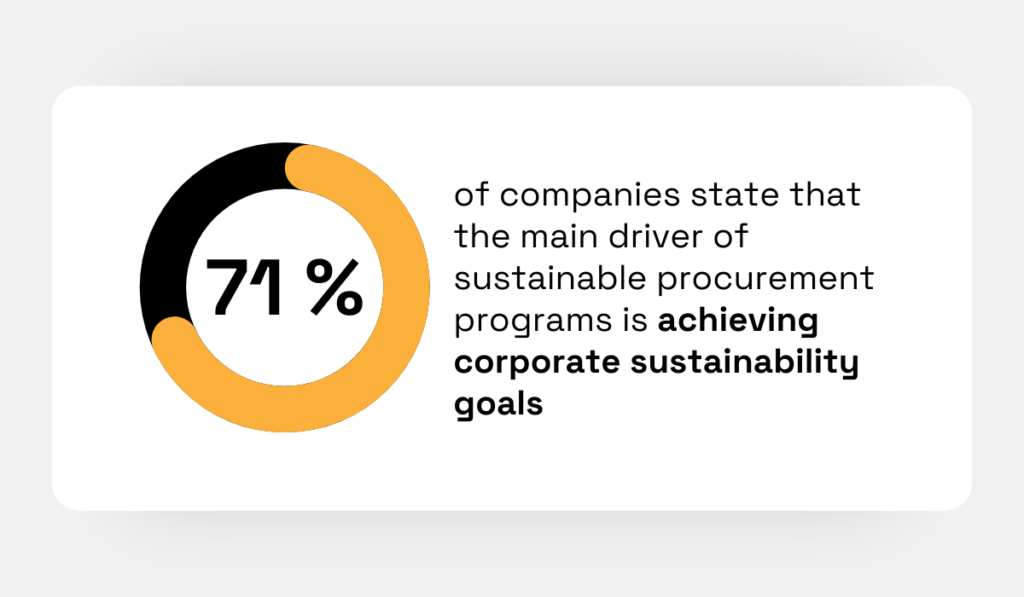

Take sustainability, for example—it’s a top priority in shaping procurement practices for over 70% of companies.

Illustration: Veridion / Data: EcoVadis

Tracking sustainability metrics, like how environmentally friendly your suppliers are or how socially responsible your procurement practices are, ensures that you’re contributing positively to these strategic goals.

On the other hand, keeping tabs on metrics like return on investment (ROI) and total cost of ownership (TCO) shows how your procurement decisions are adding value to the company’s overall strategy.

In the end, measuring KPIs really isn’t just about numbers but about showing the real impact of your procurement efforts on your company’s success.

And today, when procurement is given more importance than ever across organizations, leveraging KPIs is the only way to show that every dollar you spend contributes to achieving your organization’s goals.

Abid Sheikh, Strategic Sourcing Manager at Unilever, reminds us that procurement KPIs are diverse.

At the same time, which ones you track depends entirely on how your organization perceives procurement and how much value it places on it:

“Different organizations will have different KPIs, however this all depends on the organization’s maturity towards the procurement function and integration of activities in a way that data can be extracted, sliced, and diced and used for the optimum level of decision making.”

Based on this diversity, procurement KPIs can be categorized into several key areas.

In the next few sections, we’ll explain what each category measures and why it is essential to track these KPIs.

As their name suggests, these KPIs revolve around how you manage finances.

They help you keep track of spending and find ways to save money, which is key for keeping your organization financially healthy.

Some of the KPIs that fall into this category include:

| Cost savings | How much money is saved through procurement strategies |

| Cost avoidance | Costs that are prevented or avoided because of strategic decisions |

| Total cost of ownership | Total cost of purchasing and owning a product |

| Spend under management | Percentage of total spend that is managed by procurement |

| Procurement ROI | Return of investment from your procurement activities |

Measuring these KPIs can help you make sure that you spend resources wisely and contribute positively to your organization’s financial goals.

To learn more about each of these KPIs and how to calculate them, take a look at our article dedicated to essential procurement KPIs.

As we already mentioned, supplier KPIs help you gauge supplier performance.

They measure how well your suppliers meet their commitments and deliver quality goods and services.

Some KPIs that you should measure in this group are:

| On-time delivery | How many times suppliers deliver on schedule |

| Supplier availability | How often suppliers had products available when you needed them |

| Supplier defect rate | Number of defective products you received from suppliers |

| Supplier compliance rate | How well suppliers adhere to your contracts |

| Supplier lead times | How quickly suppliers fulfill orders |

Monitoring these supplier performance metrics helps you reduce supplier-related and supply chain risks, as well as maintain high standards throughout your supply chain.

Risk management KPIs focus on identifying and minimizing potential disruptions within your supply chain.

By keeping an eye on these metrics, you can more easily prevent disruptions that would make you lose money or halt your operations.

Risk management KPIs include:

| Supplier risk assessment | Stability and reliability of your suppliers |

| Supply chain risks | Geopolitical risks, trade restrictions, environmental risks, demand fluctuations, price volatility, etc. |

| Inventory risks | Stockouts, overstocking, inventory inaccuracy, returns and recalls, etc. |

As you can see, there are many risk management KPIs under each of these sections because there are as many procurement risks out there as you can count.

Still, tracking at least some of these will help you manage risks better and protect your procurement, reputation, and bottom line.

The last category we will talk about is sustainability.

Sustainability KPIs measure how environmentally and socially responsible your procurement practices are.

They focus on promoting ethical sourcing, reducing environmental impact, and ensuring compliance with regulations.

Some specific sustainability KPIs are:

| Carbon footprint | Total greenhouse gas emissions from procurement activities |

| Recycled material usage | Amount of procured materials that are recycled or renewable |

| Supplier diversity | Percentage of procurement spent on diverse suppliers (minority-owned, women-owned, etc.) |

| Labor practices compliance | Percentage of suppliers that adhere to fair labor practices |

After all, when you have this sustainability data, you can be fully transparent about where your products come from, how they are made, and in what circumstances.

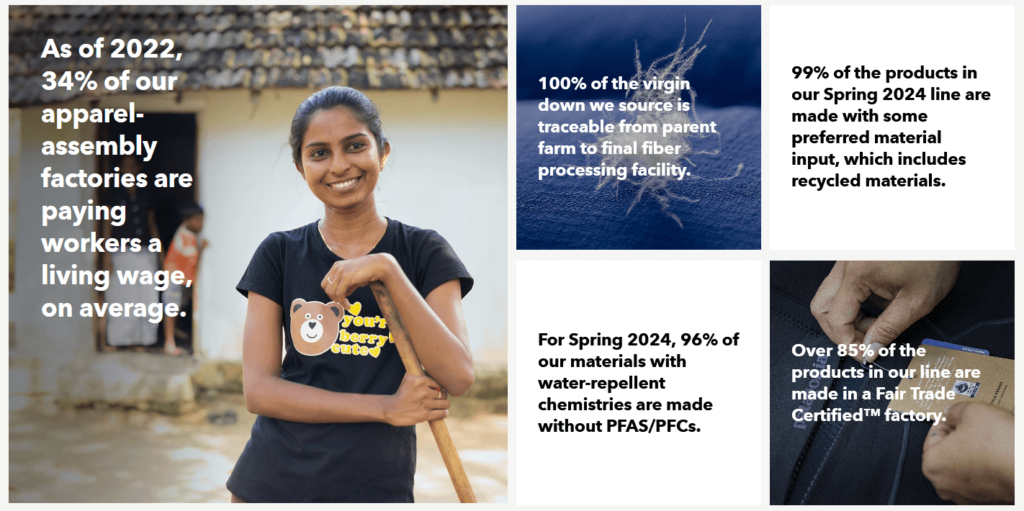

Patagonia is a company that actively tracks and measures its sustainability KPIs through ESG criteria to continually improve its practices.

And, as you can see below, the results are nothing less than remarkable.

Source: Patagonia

This focus on sustainability is critical in consumer-driven markets where ethical considerations influence purchasing decisions across various industries, from food and beverage to fashion.

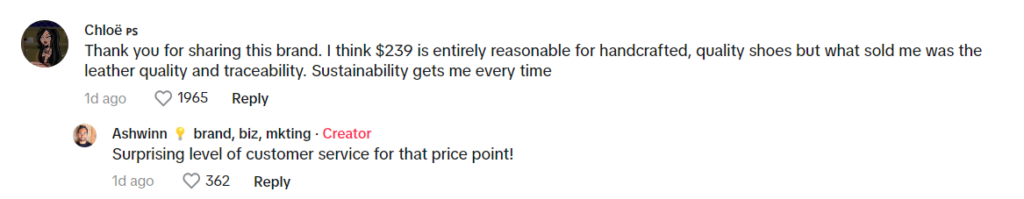

Users on social media platforms like TikTok often highlight their appreciation for brands that prioritize sustainability, transparency and ethical practices.

Comments such as the one you can see in the screenshot below support that claim.

Source: TikTok

Let’s conclude by emphasizing that only by tracking sustainability metrics will you be able to build transparency, enhance your brand reputation, and meet consumer expectations in a socially conscious market.

So, make sure to include this KPI category in your tracking efforts!

To measure procurement KPIs, you first need to track all the necessary data.

Doing this manually—gathering data from purchase orders, contracts, and invoices—is too time-consuming and resource-intensive.

That’s why it’s essential to have procurement software in place to reduce the burden on your employees.

Such a tool automates many procurement processes, including:

When these processes are automated within a single tool, the software automatically gathers and stores all relevant data in real time.

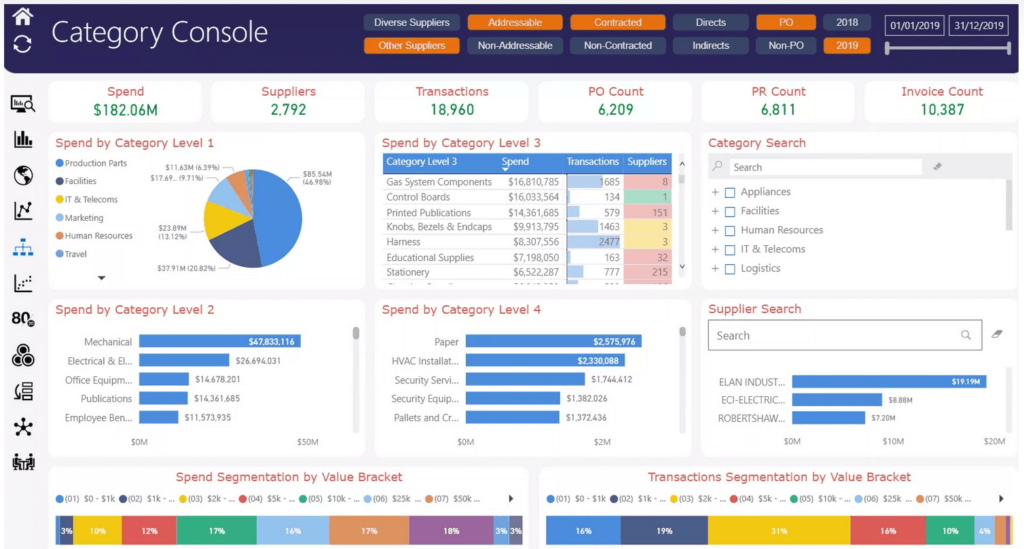

Moreover, it can analyze and display this data in a dashboard in the form of KPIs or generate reports within seconds, like in the example below.

Source: Simfoni

Procurement software will, therefore, make it easy and convenient to collect the data you need and transform it into valuable key performance indicators.

However, this internal data sourced from POs, invoices, contracts, etc., may not suffice, especially when it comes to risk management KPIs.

For robust risk assessment, especially supplier-related, you need fresh and accurate supplier data.

The most convenient way to get this information is through big data platforms.

Our very own tool, Veridion, is a leading solution because it continually gathers fresh and accurate data on millions of global suppliers using AI-powered algorithms.

Source: Veridion

This data includes supplier size, location, product specifics, compliance records, certifications, and sustainability practices.

Veridion will, therefore, provide you with fresh data on suppliers and related risks already in the sourcing stage.

Later, after you decide to work with only the best suppliers, Veridion will continually assess supplier risks and alert you about risk factors and suspicious activities in real time.

Source: Veridion

But we are not just blowing smoke here.

In PwC’s report from 2023, 57% of procurement professionals reported better decision-making based on risk insights that they got from such tech solutions.

Therefore, integrating big data platforms like Veridion and using robust procurement software seems like a wise decision for easier tracking and measuring procurement KPIs and better decision-making.

So, don’t miss out on these valuable tools!

And that wraps up our guide on procurement KPIs.

We hope we made it clear that tracking these metrics is essential for understanding how your procurement functions and pinpointing bottlenecks and areas for improvement.

Admittedly, managing all these KPIs may seem overwhelming.

That’s where procurement software and other technologies come in handy.

These tools automate processes and gather, store, and analyze data effortlessly, simplifying KPI tracking and measurement.

So, make sure you have these tools at your disposal and diligently track the KPIs we discussed today.

They will not only improve your procurement efficiency and add value to procurement but also support sustainability efforts and meet the expectations of today’s conscientious consumers.