5 Invaluable Benefits of Setting Procurement Goals

Setting clear and specific procurement goals allows your company to create strategies on how they can be achieved, implement those strategies, and measure their progress.

These goals act as a roadmap, guiding the procurement team toward specific outcomes that align with your organization’s broader strategic objectives.

Ultimately, the efforts invested in realizing these procurement goals lead to some invaluable benefits for your company.

In this article, we’ll explore five such benefits and the corresponding goals you should set to achieve them.

Alongside achieving cost savings, increased productivity is a paramount objective for companies and their procurement teams across all industries.

In procurement, this includes optimizing internal workflows within different functions as well as external processes involving suppliers and other supply chain partners.

This section will focus on goals and strategies to increase the efficiency of your internal procurement processes.

The later section on supplier management will address optimizing external supplier relationships and supply chain dynamics.

So, what objectives can you set to improve your company’s internal procurement workflows?

Here are some of the most effective ones.

Source: Veridion

These goals can be formulated more specifically and implemented selectively depending on your needs.

Your choice depends on which stages of your procurement process are not productive enough, i.e., either take too long or consume too many resources.

Sometimes inefficiencies are obvious, but they can also be hard to pinpoint.

That’s why the above productivity-boosting procurement goals include conducting an initial audit and regular reviews of existing procurement processes to identify inefficiencies, bottlenecks, and areas for improvement.

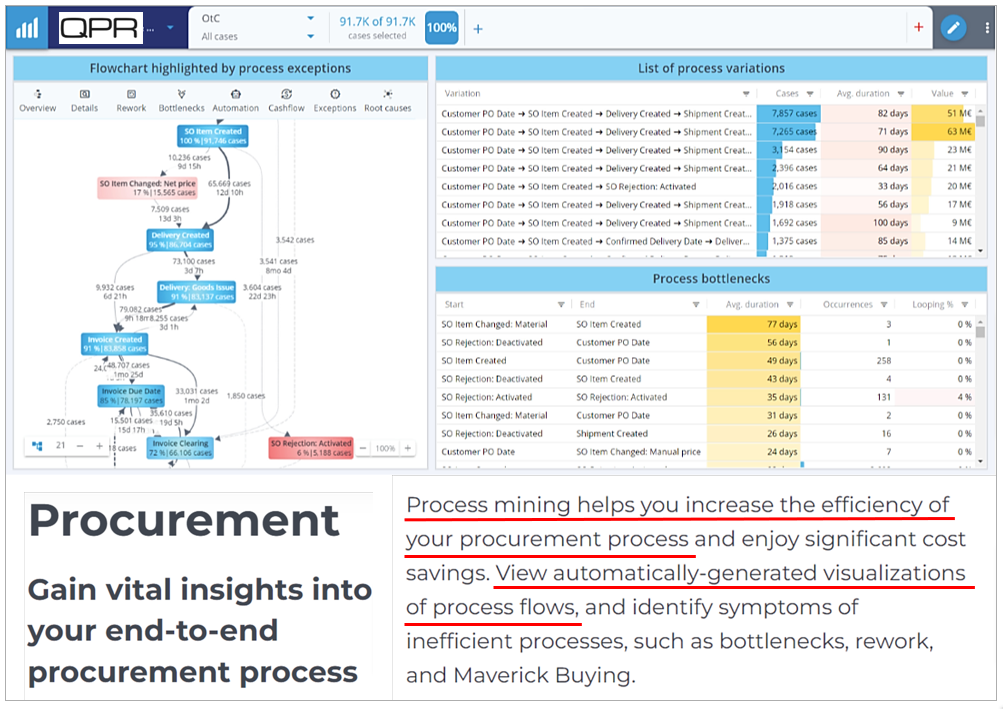

This review of procurement processes can be streamlined by using process mining tools like QPR, as highlighted below.

Source: QPR

Such tools can extract data from your digitized business systems to automatically visualize your existing processes, enabling you to identify inefficiencies.

Combining such procurement software solutions with management methods applies to all procurement goals mentioned in this article.

For instance, developing Standard Operating Procedures (SOPs) for procurement and conducting appropriate training sessions is an effective way to standardize and streamline procurement operations.

Most of these processes can be digitized and facilitated by using procurement management systems like SAP Ariba, Oracle Procurement Cloud, or Coupa.

The same approach applies when your goal is to centralize and consolidate procurement data.

While data governance policies can ensure the integrity and accuracy of data, your team’s productivity will benefit more from ensuring that all procurement data is available in a centralized, easily accessible database.

Tools like Semarchy can help with that.

Source: Semarchy

Similarly, many procurement processes can be accelerated with procurement automation tools and AI-driven big data platforms.

For example, one of the generally most time-consuming tasks is supplier sourcing, i.e., finding, vetting, and selecting new suppliers.

While this process can sometimes take months to cover only a limited number of prospective suppliers, McKinsey’s experts found that the sourcing time can be reduced by 90% or more.

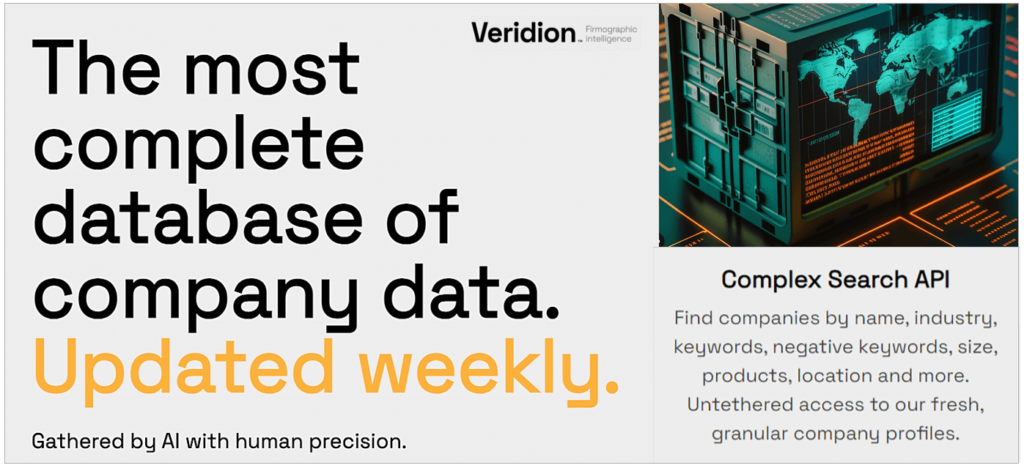

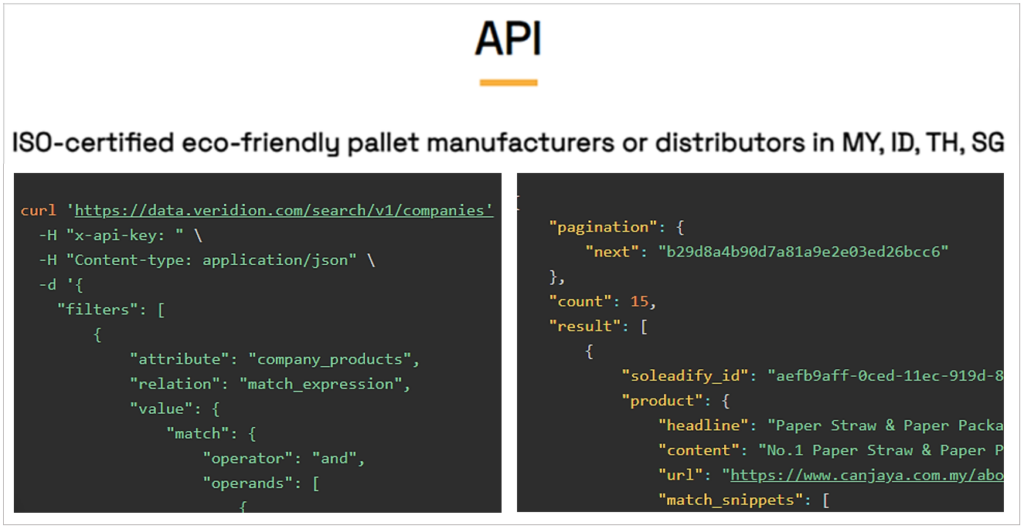

One tool that empowers procurement teams with such a productivity boost is our supplier sourcing platform, Veridion.

Source: Veridion

Veridion provides your team with a global, weekly updated supplier database with over 80 million companies whose data is collected and curated by our proprietary, AI-driven internet-searching algorithms.

This comprehensive database can be easily searched using natural language input through our Complex Search API.

Source: Veridion

And it seamlessly integrates with your other procurement management tools.

These Veridion’s features enable your procurement team to quickly and easily discover potential suppliers that fit a range of specific procurement criteria.

This can be anything from precise product specifications to suppliers’ production capacity, industry certifications, and sustainable/ethical business practices.

Since criteria setting can be done in a few minutes and search results obtained in a few seconds, this significantly reduces the supplier sourcing time.

From there, you can use e-sourcing tools to streamline the process of contacting the shortlisted candidates, sending requests for proposals (RFPs), selecting suppliers, negotiating terms, and awarding contracts.

Lastly, centralized procurement data integrated with other systems can encourage communication and collaboration across departments.

By now it’s clear that increasing the productivity of internal procurement processes involves setting specific goals and using a combination of advanced software tools and effective management methods to achieve them.

Cost savings are a universal objective for companies and their procurement departments.

Similar to productivity-increasing goals, achieving cost reductions requires procurement teams to first identify potential opportunities.

Some of these opportunities are obvious, such as negotiating volume discounts with suppliers to reduce prices.

However, others may be more elusive.

Therefore, we’ll focus on specific goals and corresponding strategies that can help your team more easily identify cost-saving opportunities.

Typically, this involves collecting and analyzing a lot of procurement data from internal and external sources to extract actionable insights.

That is hard to do without technology.

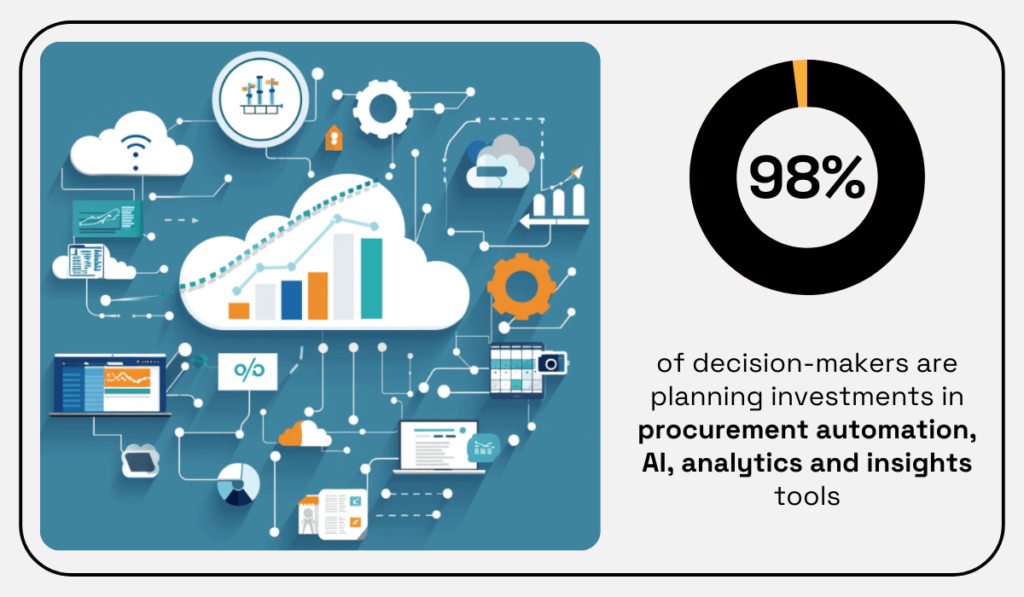

Luckily, decision-makers in companies recognize this and are willing to invest in tech, as evidenced in Amazon’s 2024 State of Procurement Report.

Illustration: Veridion / Data: Amazon

So, what goals can you set for better detection of potential cost-savings that procurement technology helps with?

We’ll highlight three:

For instance, running a systematic analysis of a company’s spending patterns enables the procurement team to uncover inefficiencies, such as maverick spending and duplicate purchases.

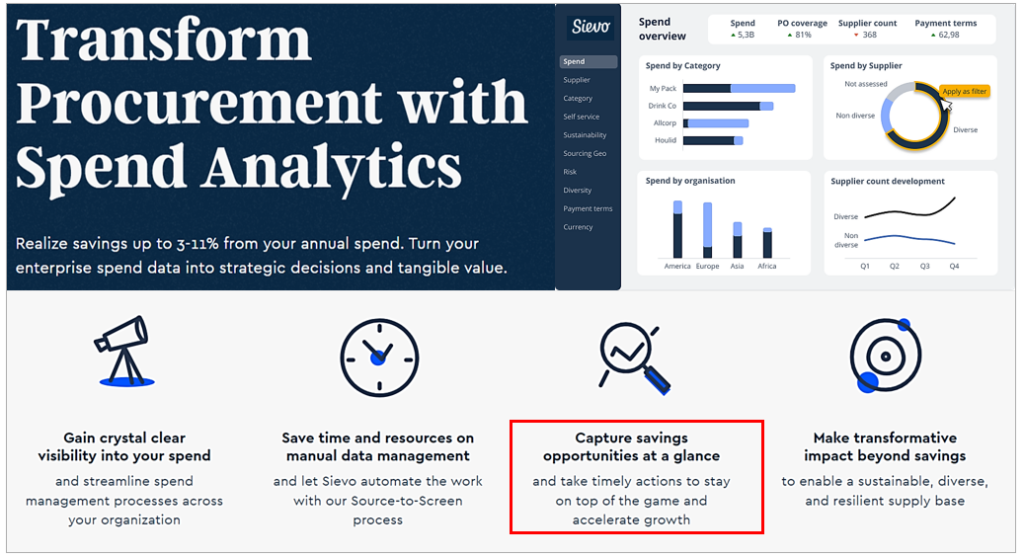

Spend analysis can be automated by a range of specialized tools or comprehensive procurement management platforms.

Source: Sievo

As highlighted, such tools provide detailed insights into where money is being spent and help your team capture savings opportunities.

Similarly, utilizing market intelligence tools can provide your company with real-time data and insights about market trends, supplier pricing, and emerging alternatives.

This then allows your team to benchmark supplier prices and other parameters, discover new, cost-effective suppliers, and take advantage of market opportunities.

Source: Veridion

Lastly, implementing advanced forecasting tools and techniques to predict future demand more accurately helps companies recognize when there’s a risk of stockouts or overstocking.

This avoids keeping excess inventory, therefore reducing inventory holding costs.

As you can see, setting the goal to use tools can help both your team and company more easily uncover a host of cost-saving opportunities, which can then be turned into appropriate cost-saving initiatives.

By setting specific goals to improve supplier management, you can strengthen supplier relationships, ensure better compliance, and drive overall performance improvements.

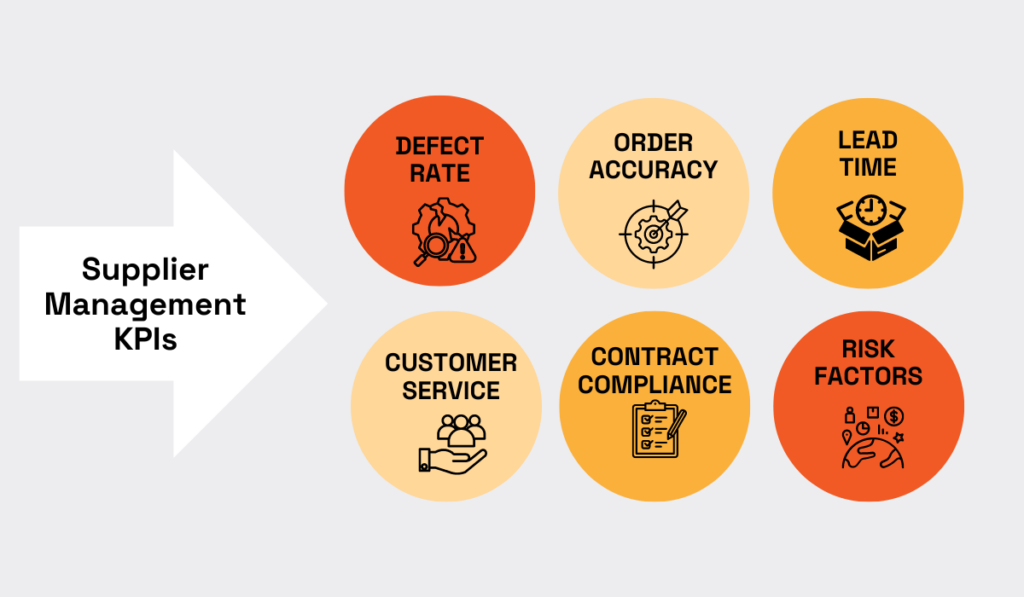

One of the fundamental goals in this regard is to establish and monitor suppliers’ key performance indicators (KPIs).

These KPIs can include a range of relevant metrics such as on-time delivery rates, quality of goods or services, responsiveness, and cost-effectiveness.

To illustrate, here are just some of them.

Source: Veridion

By regularly tracking these and other KPIs using supplier management tools, your team can identify high-performing suppliers and address issues with underperforming ones.

This ongoing monitoring drives continuous improvement and strengthens relationships, leading to more successful supplier management.

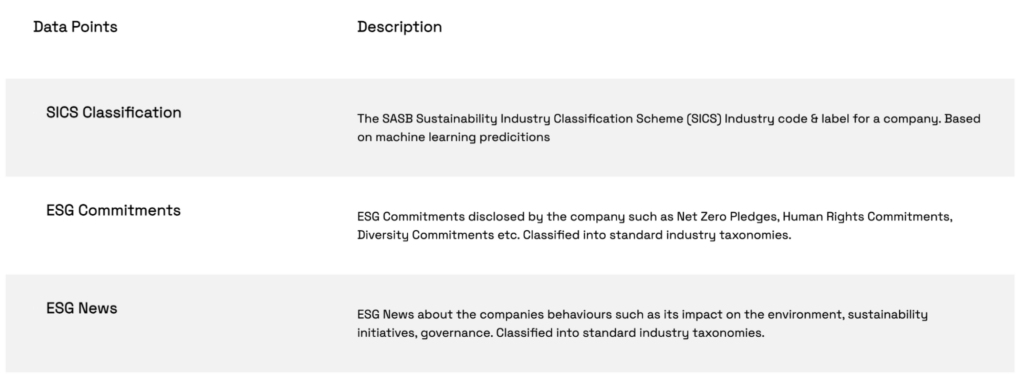

As environmental sustainability and fair labor practices have become a priority for consumers and regulators, another critical goal is to promote and support supplier sustainability initiatives.

This starts with selecting suppliers that adhere to your company’s environmental and social governance (ESG) goals.

Source: Veridion

Beyond selecting sustainable suppliers, you can use sustainability-related KPIs to monitor supplier compliance and set improvement goals for them.

These supplier improvement goals can range from reducing their carbon footprint and using more sustainable raw materials to improving working conditions at their locations.

Another major goal that can lead to more successful supplier management is to enhance collaboration with suppliers, streamline communication, and drive joint value creation.

This can involve organizing joint planning (to align with your demand forecasts) or problem-solving sessions and collaborative innovation initiatives.

For example, Tesco connects sustainability start-ups with their major suppliers to help them scale their innovations in the real world while also improving suppliers’ ESG standards.

Source: Tesco

Of course, supplier improvement initiatives go beyond sustainability standards and can include any aspect of your supplier relationships.

By using the right supplier management tools and methods, such initiatives can improve supplier performance and contribute to the company’s overall strategic objectives and supply chain resilience.

Therefore, focusing on goals like establishing and monitoring supplier KPIs, promoting sustainability, and enhancing collaboration and innovation enables your company to achieve more successful supplier management.

As a complex process typically involving many stakeholders, supply chain activities have always been exposed to a myriad of risks.

However, events in recent years, from health crises to geopolitical conflicts and climate change, have put resilience to procurement risks at the top of companies’ priorities.

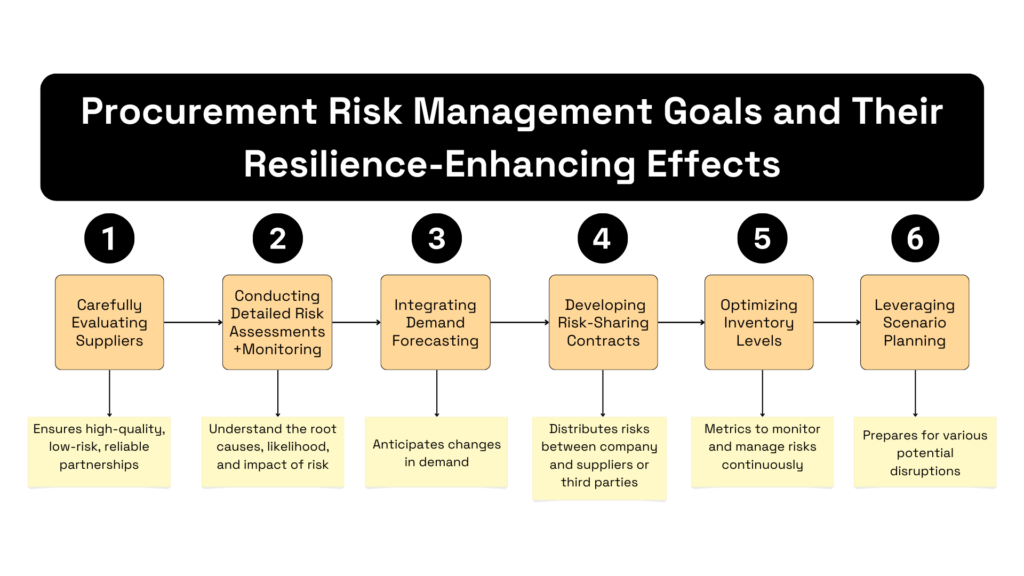

So, what goals can you set that will help your organization successfully mitigate procurement risks?

Here are some suggestions illustrated.

Source: Veridion

As shown above, one goal could be empowering your team to carefully evaluate potential suppliers.

This ensures that you partner only with those who meet your quality and reliability standards, reducing the likelihood of supplier-side disruptions.

Likewise, a goal of conducting comprehensive risk assessments of potential suppliers and monitoring current ones for risk emergence helps identify potential risks before they materialize, enabling you to develop targeted mitigation strategies.

When selecting suppliers, increased resilience to risks may be achieved by avoiding high-risk suppliers or employing other appropriate risk management methods to mitigate the identified risks.

As for risks associated with existing suppliers, enhanced resilience can be accomplished by monitoring:

Of course, this requires using risk management tools, such as supplier management software for tracking KPIs and supplier data platforms for monitoring outside risks.

Even a supplier sourcing enabler like Veridion can help in that regard.

Source: Veridion

Next, the goal of creating risk-sharing contracts or clauses can ensure that risks are distributed fairly between your company and suppliers or transferred to third parties (e.g., insurance).

Or, you might set up a goal like planning different risk scenarios.

In that case, using tools to run these scenarios lets you plan for potential disruptions and develop relevant risk mitigation measures and contingencies.

Overall, increased resilience to procurement risks involves setting specific risk management goals. Only after setting them, you can identify appropriate strategies to achieve them.

One overarching benefit of setting clear and measurable procurement goals is that they ensure a higher level of accountability for all involved stakeholders.

For instance, by standardizing and streamlining procurement processes and approval workflows, you make everyone more accountable for their actions.

This is because any deviation from the set procedures and guidelines can be tracked and addressed, ensuring that everyone follows the same protocols or is held responsible for not doing so.

Similarly, quality and performance goals for suppliers ensure that suppliers are held to elevated standards.

Of course, it’s not enough to just set those goals.

You should also monitor supplier compliance through regular performance reviews and audits and define consequences for non-compliance.

Here’s how others do that:

Source: IEWC

That way, you ensure suppliers are accountable for consistently meeting the defined quality, delivery, and sustainability expectations.

The same applies to setting internal performance goals for your procurement team, such as a specific reduction in the supplier sourcing time or a specific percentage of cost-savings achieved.

Such benchmarks provide objective criteria for evaluating individual and team performance, identifying gaps, and facilitating corrective actions when necessary.

The bottom line, measurable goals foster higher accountability among all stakeholders, leading to more efficient, reliable, and transparent supply chain operations.

Let’s underline that goal setting enables procurement specialists to implement appropriate strategies and monitor progress toward each goal.

With a clear roadmap and the right tools, the efforts invested in achieving procurement goals can be turned into valuable benefits: from improved productivity and cost-savings to less risky business.

Lastly, these goals and tools bring visibility, resulting in higher accountability for all involved.

So keep setting those goals for more productive and profitable procurement operations.