What Is Strategic Procurement Planning

Any planning in procurement can be more or less strategic.

However, there’s a big difference in planning procurement with a clear focus on long-term strategic goals, supplier relationships, and value optimization versus simply managing day-to-day purchasing tasks.

That’s why, in this article, we’ll explore what strategic procurement planning is, what benefits it brings, and how you can improve your approach to it.

So, without further ado, let’s delve in.

Strategic procurement planning is a comprehensive approach to managing an organization’s procurement processes with a focus on long-term goals and value creation.

Unlike traditional or transactional procurement, which often centers on short-term needs and cost-cutting, strategic procurement emphasizes:

At its core, strategic procurement planning involves setting clear objectives, conducting thorough market research, and developing a robust procurement strategy that supports your organization’s mission and vision.

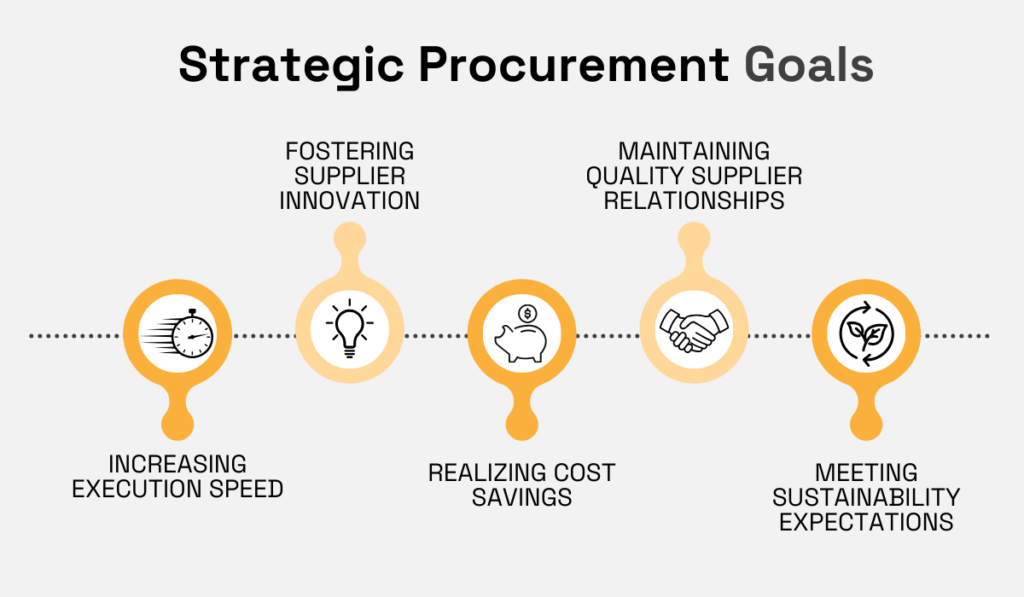

Therefore, it all starts with defining strategic procurement goals.

Here are some general ones.

Source: Veridion

At first glance, these goals might seem applicable to most procurement teams.

However, clearly outlining them gives each company the basis for turning them into strategies and actions specifically tailored to achieve the set targets.

More precisely, these broad goals should be translated into specific objectives and then refined into actionable efficiency-raising or cost-saving initiatives.

That way, companies can create a clear roadmap for their strategic procurement activities that supports their overall business strategy and delivers long-term value.

Although some of the identified areas for improvement might require investment and may not produce immediate savings, they will ensure long-term sustainability and competitive advantage.

For instance, meeting sustainability expectations might involve initially higher costs of transitioning to sustainable sourcing.

However, they often result in long-term cost savings that can’t be ignored.

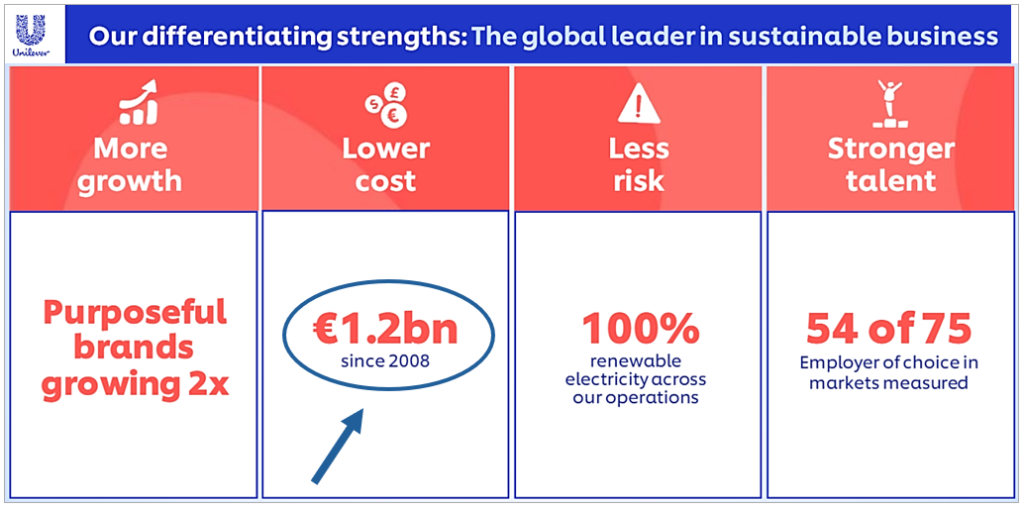

Take Unilever, for example.

Unilever’s 2020 report highlights that the company saved $1.2 billion through sustainable sourcing since 2008, while also enhancing its brand growth, increasing energy security, and attracting new talent.

Source: Unilever

This example shows how strategically transforming your company’s procurement practices towards more sustainable outcomes—and communicating this to the public—can yield far more benefits than just cost savings.

So, in addition to clearly defining goals and extracting actionable objectives, what does strategic procurement planning actually involve?

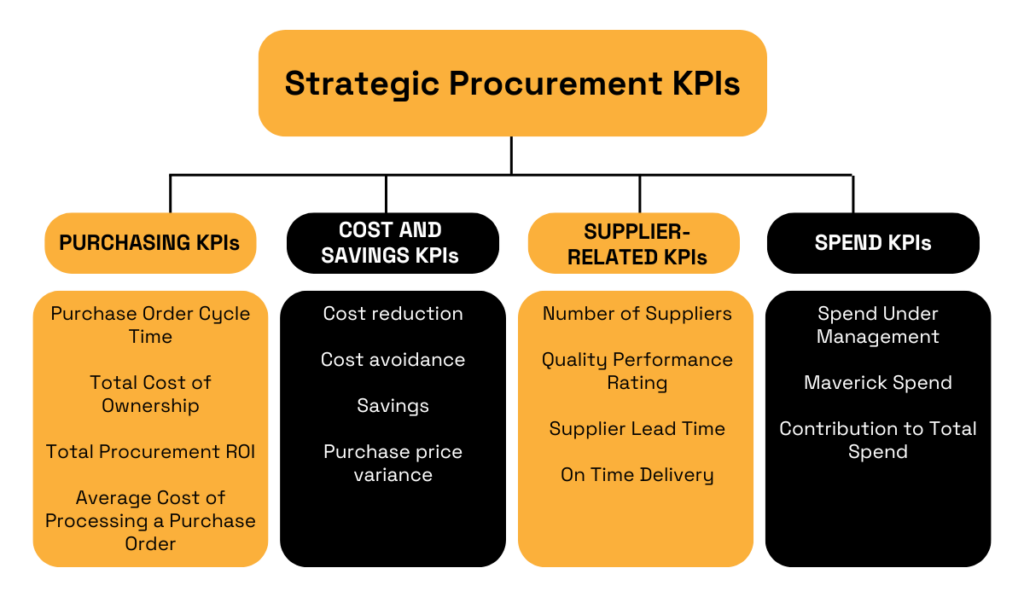

In short, a range of tools for planning, as well as key performance indicators (KPIs) for monitoring progress.

Tools commonly used in strategic procurement planning include spend analysis, supplier performance management, and procurement software solutions.

Essentially, these software tools both provide data-driven insights and streamline various procurement tasks.

As mentioned, another key aspect of strategic procurement planning is the identification and use of KPIs to monitor and evaluate your company’s internal procurement processes and your suppliers’ performance.

There’s a whole range of KPIs relevant for strategic procurement, as illustrated below.

Source: Veridion

Monitoring these and other KPIs allows companies to make informed decisions about all aspects of their procurement operations, including:

Additionally, effective strategic procurement planning requires a collaborative approach involving various stakeholders across the company, as we’ll discuss later on.

For now, it’s important to note that stakeholder engagement helps ensure that procurement strategies are aligned with the company’s broader business objectives and that all relevant perspectives are considered.

To recap, strategic procurement planning involves translating a company’s long-term strategic objectives into its procurement team’s specific goals and tasks.

Ultimately, this process generates many advantages, as discussed in the next section.

By focusing on long-term value creation, strategic procurement planning offers a myriad of opportunities for companies to enhance their efficiency and competitiveness.

Beyond the benefits we’ll cover in this section, strategic procurement planning also aids in meeting sustainability expectations, fostering procurement innovation, and maintaining quality relationships with suppliers.

Now, let’s explore three key advantages in more detail: shorter procurement timelines, cost savings, and improved quality of procured goods.

There are numerous methods to reduce the overall procurement time, i.e., the duration of specific processes, such as:

While some of these methods may involve changing work methodologies or strengthening the procurement team’s capacity, almost all of them also include leveraging various digital tools and solutions.

Therefore, incorporating a phased adoption of technology—along with appropriate training and change management efforts—into your strategic procurement plan can provide generous returns, including improved procurement timelines.

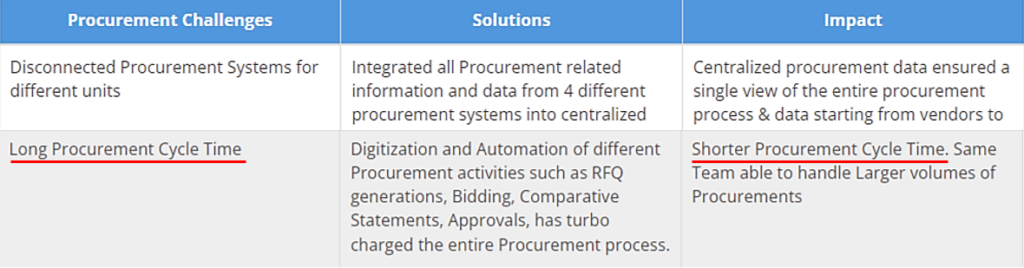

For example, a company can implement a centralized e-procurement platform to streamline internal processes and reduce cycle times.

Below, you can see the results of a case study where a company with four production plants exchanged its separate procurement software solutions with a single, integrated e-procurement platform.

Source: Force Intellect

As highlighted, digitization and automation can significantly reduce the time needed to perform many procurement processes, from quickly generating various requests (RFXs) to accelerating approvals.

Of course, there are other methods to reduce procurement timelines that can be considered when planning strategic procurement, such as:

In short, one of the benefits of strategic procurement planning is that it can consider and address how both internal and external processes can be improved to maximize efficiency and minimize procurement time.

Strategic procurement planning enables companies to achieve better value for money by focusing on overall cost-effectiveness, rather than just the lowest price.

This approach emphasizes thorough supplier negotiations and evaluates the total cost of ownership (TCO), and not just the initial purchase cost.

For instance, a company might select a supplier offering a slightly higher initial price.

But why would anyone want that?

Well, if such a supplier offers superior product durability and robust control processes, this leads to fewer expenses related to faulty components or materials and greater overall savings.

Likewise, as in the case of Unilever, a company might consider that it gets better value for money from suppliers committed to sustainability practices, despite sometimes initially higher costs.

This is what Unilever’s former CEO, Alan Jope, had to say about this:

Illustration: Veridion / Data: Supply Chain Dive

This statement illustrates what many surveys have established: cost savings and sustainability can be achieved together, but typically with a longer time horizon.

For instance, a 2022 EY survey of 525 supply chain executives revealed that 80% of them are increasing their efforts towards achieving supply chain sustainability.

Moreover, 61% said that cost savings and efficiency are the main motivators for their company’s sustainability efforts.

This includes strategic measures like ensuring supply chain decarbonization, efficient resource use, ethical sourcing, and fair trade.

In summary, strategic procurement planning is all about optimizing value for money over the long term, considering factors beyond just the initial purchase price.

Since strategic procurement planning involves rigorous initial supplier evaluation and performance monitoring, this helps ensure that all procured goods and services meet the necessary standards and specifications.

Of course, it all starts with your company establishing clear:

From there, these requirements can be turned into specific procurement criteria.

Then, assuming a long-term, strategic approach, often the most time-consuming procurement task begins:

Finding potential suppliers who meet your quality and performance requirements.

This process can be significantly enhanced by utilizing advanced, AI-powered solutions like our supplier sourcing tool, Veridion.

Source: Veridion

As illustrated, Veridion offers access to a vast global database of suppliers, updated on a weekly basis and with over 80 million companies and 200 million business locations.

Moreover, Veridion comes with two AI-driven search APIs easily integrated with other procurement management solutions.

They facilitate swift supplier discovery, evaluation, and risk assessment.

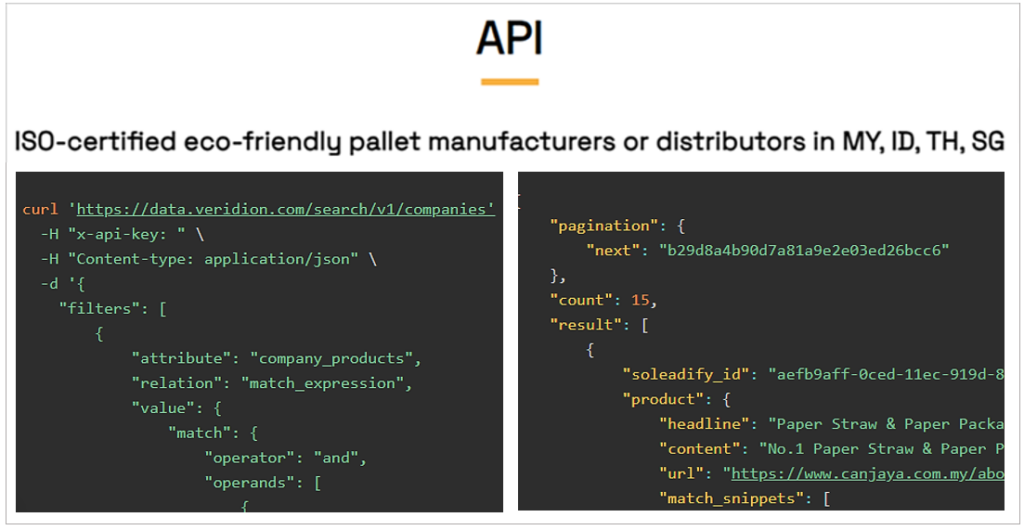

With our company search service, you can use natural language input to efficiently identify suppliers that meet your required quality standards and possess the necessary industry certifications.

Source: Veridion

In addition to enabling procurement teams to quickly find suitable candidates that fit specific quality criteria, they can also screen them against sustainability (ESG) criteria.

That way, potential supplier non-compliance with environmental and labor regulations or standards can be prevented from turning into quality or delivery issues and disruptions.

As for monitoring supplier performance, Veridon can facilitate this process by enabling companies to set supplier-specific risk parameters and receive real-time alerts, as discussed later.

To recap, clear quality specifications and standards, technology-assisted supplier evaluations and monitoring, and strategic relationship building can help companies increase the quality of procured products and services.

As mentioned, strategic procurement planning involves a set of tools and methodologies that enable teams not only to plan, but also monitor and update their procurement practices.

Such procurement management tools and methods, coupled with employee training and skills building, form the backbone of your strategic procurement planning.

So, here are three things you can do to improve your approach.

To stay informed, anticipate changes, and plan strategic procurement activities accordingly, it’s crucial to regularly analyze market trends, supplier markets, and industry developments.

Simply put, the world is moving too fast, and companies can’t afford to make business decisions based on outdated or incomplete information.

That’s why conducting market research is an essential component of strategic procurement planning that enables companies to:

Again, big data platforms with the latest market intelligence and powerful data analytics can automate many aspects of this otherwise resource-intensive process.

Source: Veridion

With access to the freshest market data needed for informed decision-making, companies can keep an eye on, for example, their competitors’ moves, advancements in technology, and changes in regulatory environments.

This ultimately enables them to adapt their business and procurement strategies accordingly, allowing for efficient and proactive strategic procurement planning.

Involving all relevant stakeholders in the procurement planning process is essential for ensuring comprehensive input and buy-in.

More precisely, your procurement planning will become more strategic as you gather diverse perspectives, needs, and wants of your company management and internal departments such as finance, operations, legal, IT, and quality assurance.

Additionally, although they’re external to the company, key suppliers and supply chain partners can also provide valuable input when planning procurement.

Here’s a broad overview of stakeholders—other than the procurement department—relevant to strategic procurement planning.

Source: Veridion

For example, the finance department can help in understanding budget constraints, input from operations can ensure that procured goods meet practical needs, and feedback from suppliers can inform the feasibility of delivery timelines.

To sum up, getting all relevant stakeholders involved in strategic procurement planning will not only foster collaboration and enhance decision-making but can also drive cost savings and innovation.

Considering recent supply chain disruptions and ongoing geopolitical tensions, effective strategic procurement planning is necessarily predicated on regularly conducting risk assessments.

Procurement risks encompass a wide array of factors, ranging from suppliers’ financial stability to their competitive and regulatory environment, market volatility, trade wars, sanctions, and natural disasters.

By identifying these risks early, procurement teams can create contingency plans and strategies to minimize their impact.

Many supplier-related risks can be averted or minimized during initial supplier selection.

As for ongoing risk monitoring, a combination of supplier management and market intelligence tools can be leveraged.

As mentioned, this is where Veridion can assist you by automating both market intelligence gathering and supplier risk monitoring.

Source: Veridion

You can set custom risk factors—such as regulatory issues or financial instability—for specific suppliers and receive real-time alerts if such risks are detected.

Coupled with monitoring of market-related risks, this enables your team to proactively identify potential disruptions and define robust risk management strategies.

These can range from diversifying the supply base to reduce overreliance on any one supplier to encouraging suppliers to implement their own risk mitigation measures.

In summary, your approach to strategic procurement planning should prioritize proactive risk management to help your company avoid or minimize the effects of market volatility and supply chain disruptions.

All things considered, strategic procurement planning is essential for optimizing procurement processes, reducing risks, and achieving long-term value.

It generates many advantages for forward-looking companies, from reduced procurement timelines to better value for money and increased quality of procured goods.

By leveraging appropriate planning tools and methods, you can make better-informed decisions and ensure your procurement activities are efficient, cost-effective, and resilient against disruptions.